Equidistant segmented cutting device for building logs

An isometric segmentation and cutting device technology, applied in woodworking safety devices, wood processing appliances, forming/shaping machines, etc., can solve the problems of dangerous operation, damage, inability to automatically limit cutting tools, etc., to prevent random movement, The effect of protecting the cutting tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

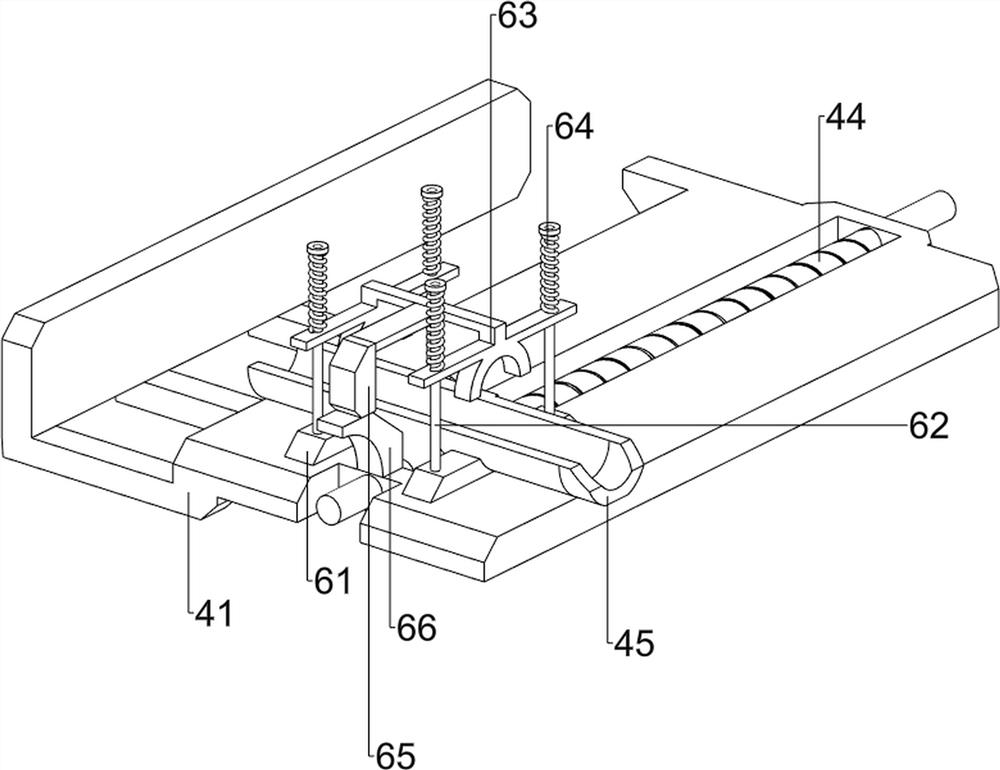

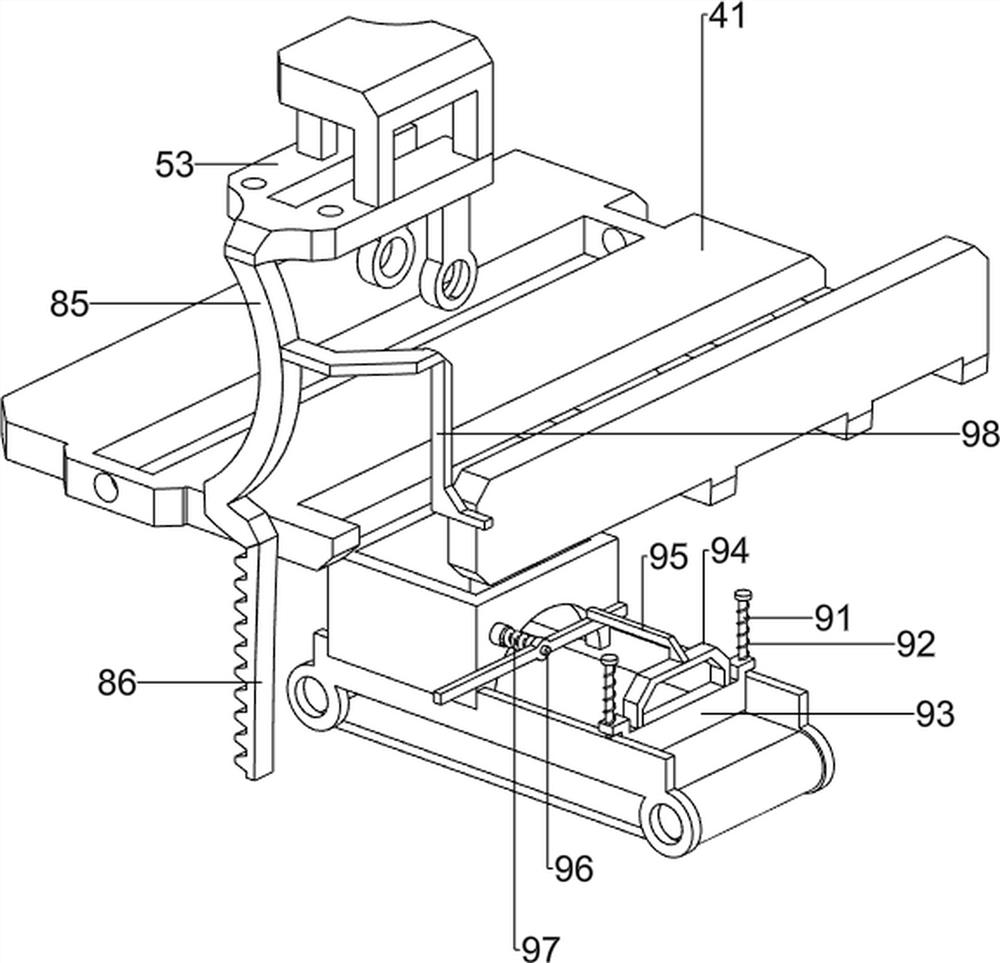

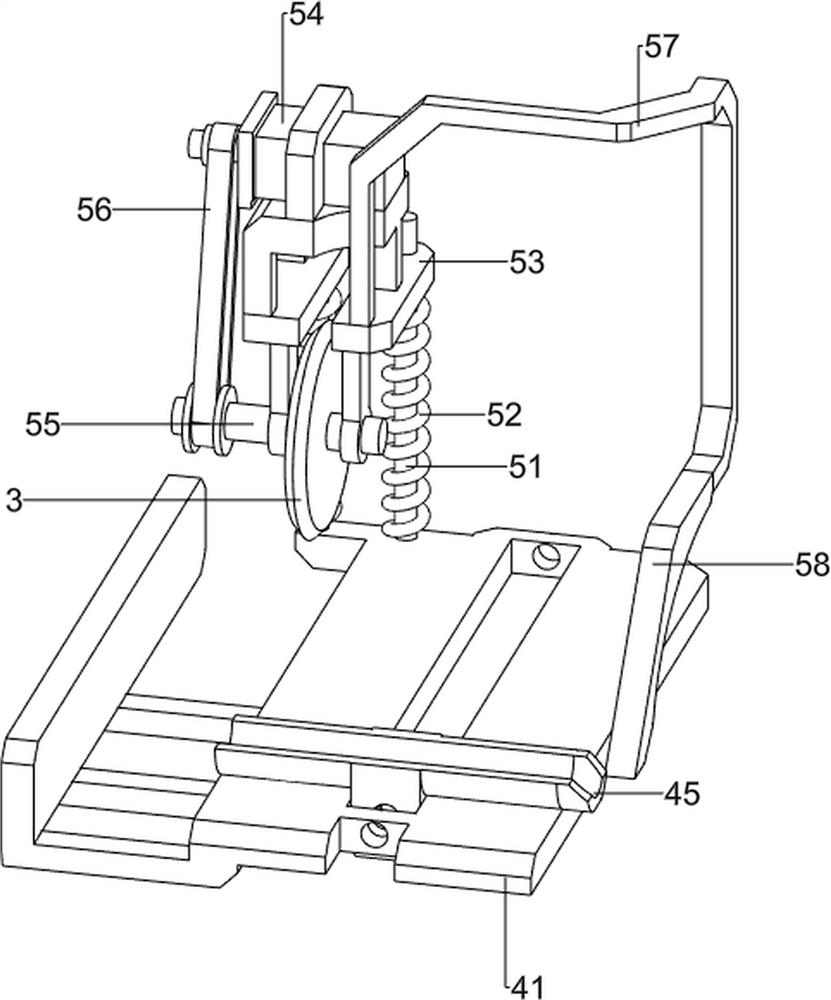

[0030] Such as Figure 1-7 A log equidistant section cutting device for construction is shown, including a base plate 1, a bracket 2, a cutter 3, a moving mechanism 4, a mounting plate 41, a first fixing frame 42, a first servo motor 43, and a screw rod 44 , arc-shaped bearing moving plate 45, pressing mechanism 5, first slide bar 51, first spring 52, mounting frame 53, second servo motor 54, first rotating shaft 55, transmission belt 56, first connecting block 57, Oblique pressing block 58, pressing mechanism 6, second connecting block 61, second slide bar 62, first pressing block 63, second spring 64, first top block 65, first bump 66, protection mechanism 7, The second fixed frame 71, the third sliding rod 72, the third spring 73, the second top block 74, the protective cover 75, the third connecting block 76, the second bump 77, the discharge mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com