Building construction sand and stone mixing device

A technology for building construction and mixing devices, applied to clay preparation devices, cement mixing devices, chemical instruments and methods, etc., can solve the problems of poor mixing effect of sand and gravel materials, inability to achieve stirring and dispersing effects, etc., achieve ingenious structure, increase mixing Effect, well-designed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

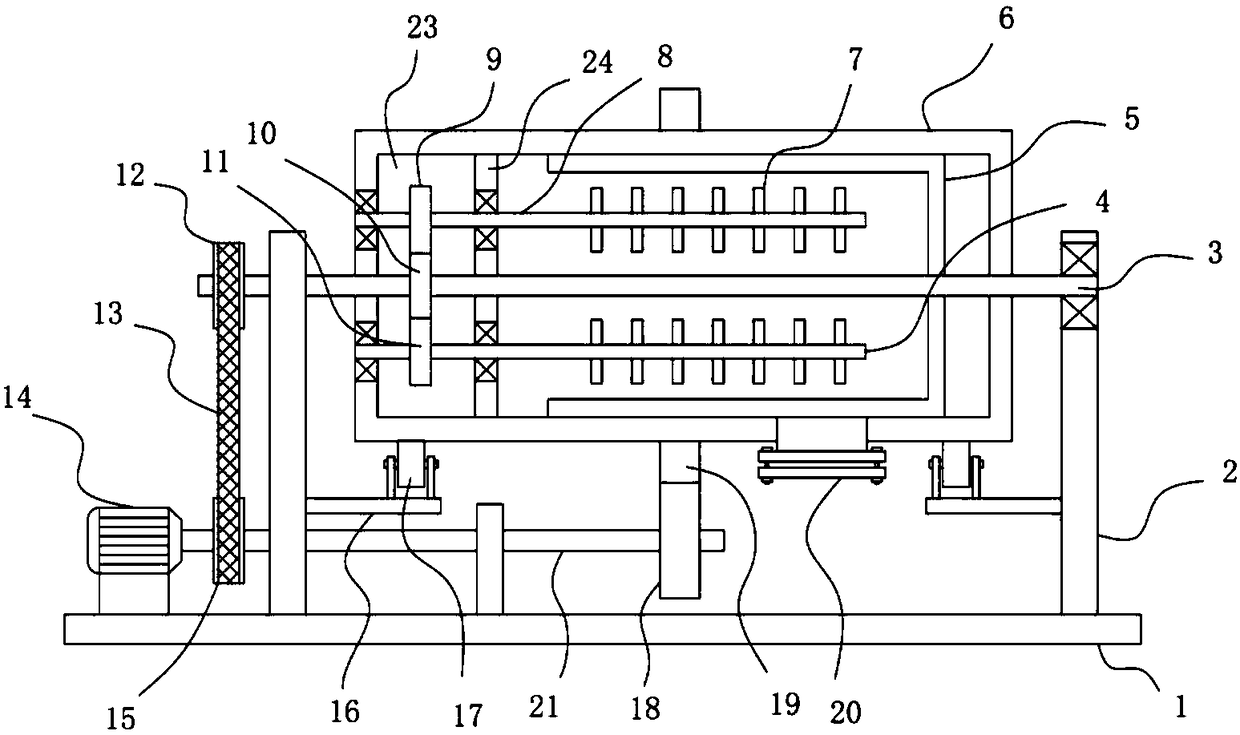

[0020] see figure 1 , a sand and gravel material mixing device for building construction, comprising a support base plate 1, two support frames 2 are vertically fixedly installed on the support base plate 1, a mixing tank 6 is horizontally arranged between the support frames 2, and the inside of the mixing tank 6 is horizontally A rotating shaft 3 connected to the support frame 2 through a bearing is worn through, and a partition plate 24 is vertically fixedly installed in the mixing bucket 6 , and the partition plate 24 and the left side wall of the mixing bucket 6 form a gear box 23 .

[0021] The gear box 23 is horizontally provided with the driven shaft II8 and the driven shaft I4 extending to the inside of the mixing tank 6, and the surface of the rotating shaft 3 is sleeved and fixedly installed with the main gear 10 located in the gear box 23, the driven shaft II8 and the driven shaft II8. The pinion gear II9 and the pinion gear I11, which are meshed with the main gear ...

Embodiment 2

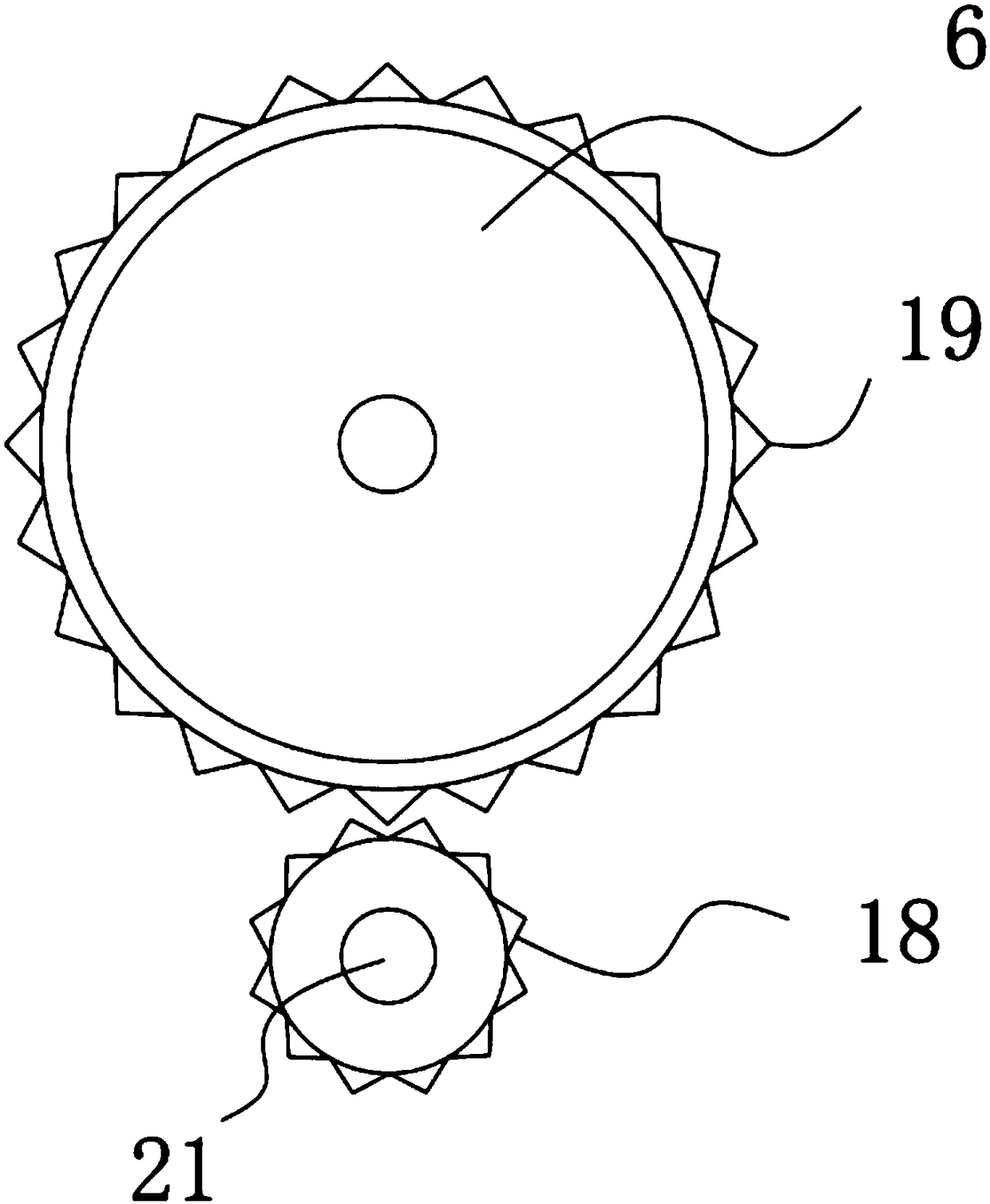

[0027] On the basis of Example 1, such as Figure 1-2 As shown, in addition, an outer ring gear 19 is sleeved and fixedly installed on the surface of the mixing bucket 6 , and a transmission gear 18 meshingly connected with the outer ring gear 19 is sleeved and fixedly installed on the surface of the driving shaft 21 .

[0028] The rotation of the drive shaft 21 drives the transmission gear 18 to rotate, and the transmission gear 18 drives the mixing bucket 6 to rotate through the outer gear ring 19 meshed with it, and the mixing bucket 6 drives the sand and gravel inside it to rotate, while the driven shaft II8 And the driven shaft I4 rotates around the rotating shaft 3, which greatly increases the stirring effect of the stirring blade 7, and the rotating direction of the mixing bucket 6 is opposite to that of the rotating frame 5, so that the mixing effect of the sand and gravel is further improved.

Embodiment 3

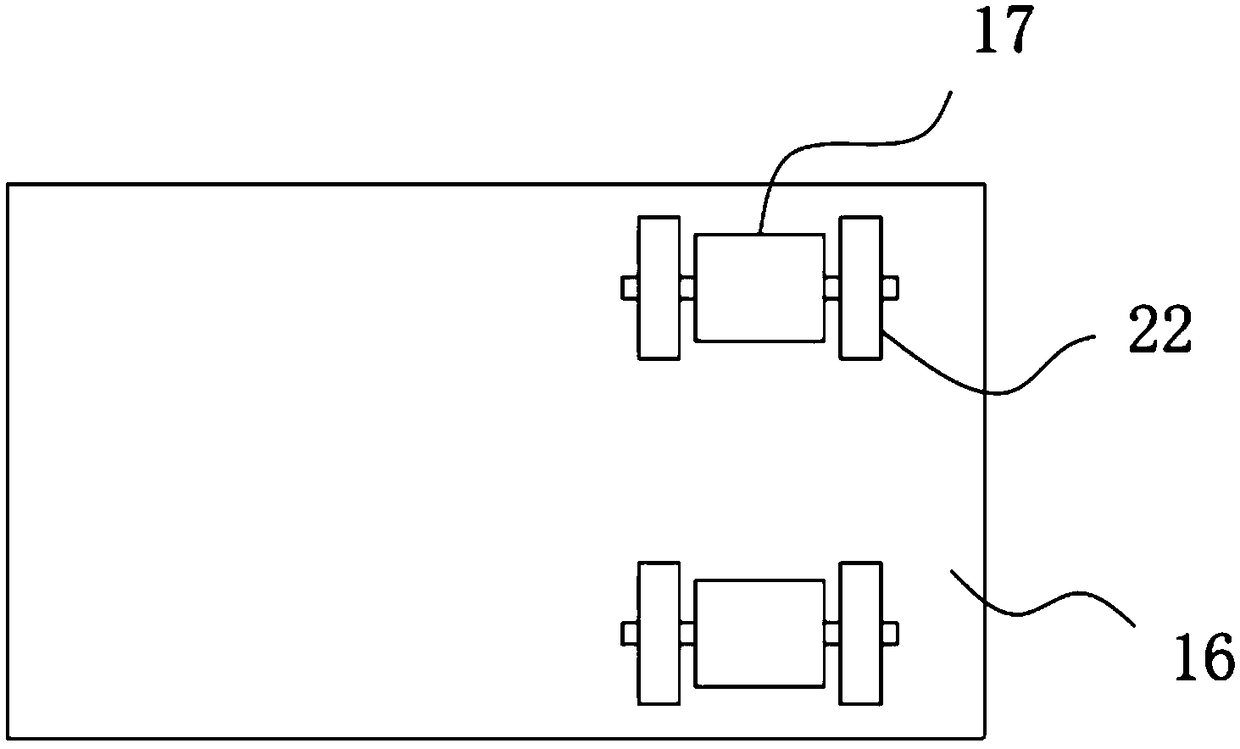

[0030] On the basis of Example 2, such as image 3 As shown, in addition, a support plate 16 is fixedly installed on the inner side wall of the support frame 2 horizontally, and two support limit mechanisms are fixedly installed on the support plate 16. Frame 22, the fixed frame 22 is provided with the guide roller 17 that abuts against the surface of the mixing bucket 6, and the distance between the two guide rollers 17 on the support plate 16 is less than the outer diameter of the mixing bucket 6. In the process that mixing bucket 6 rotates, mixing bucket 6 can drive the guide roller 17 that abuts against it to rotate, and guide roller 17 plays a supporting role to mixing bucket 6 on the one hand, plays a role in supporting the mixing bucket on the other hand. The guiding function of 6 rotations ensures the smooth rotation of the mixing tank 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com