Stirring machine for plastic product production

A technology for plastic products and mixers, which is applied in the field of mixers for the production of plastic products, can solve the problems of inability to produce plastic products, inconvenient use of mixing devices, and increased maintenance costs, and achieves the effects of low replacement cost, simple structure, and improved mixing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

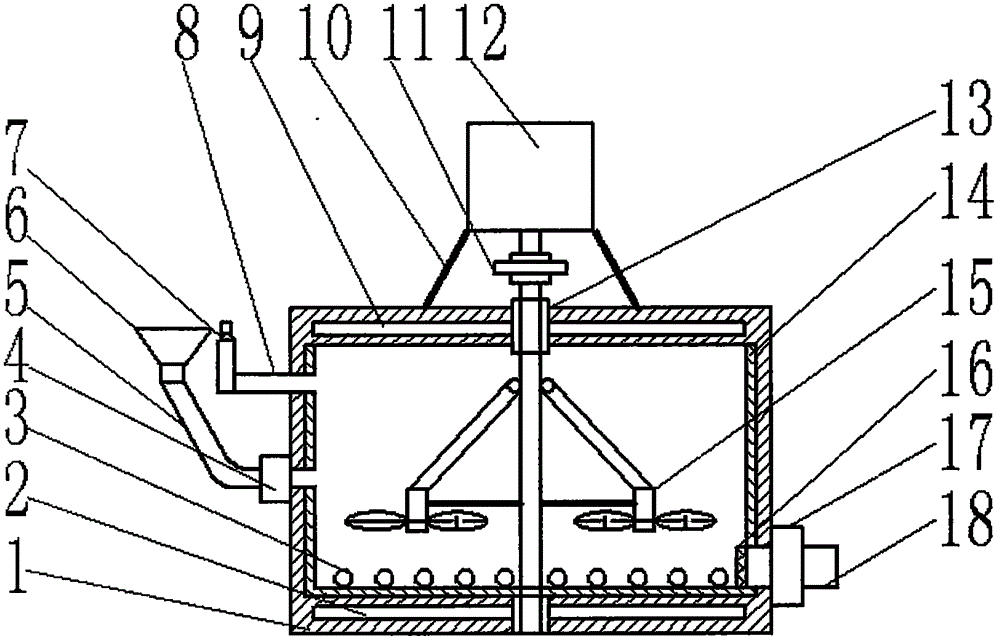

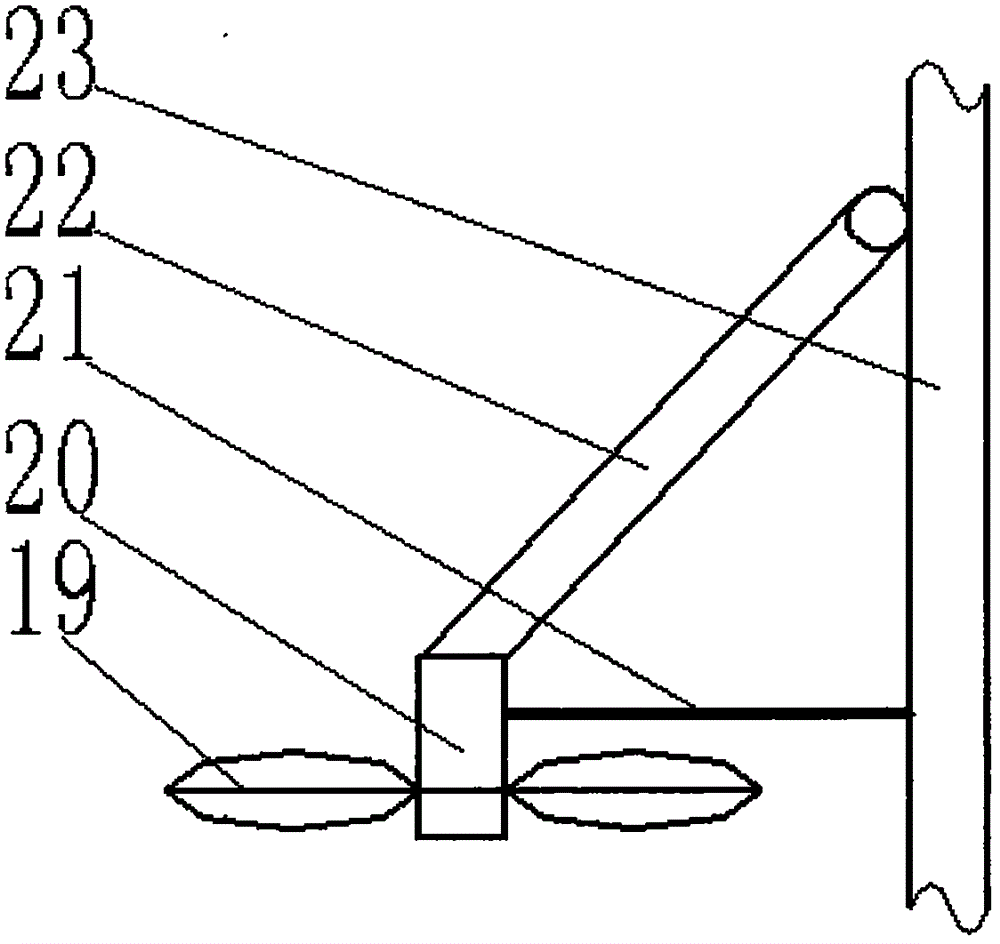

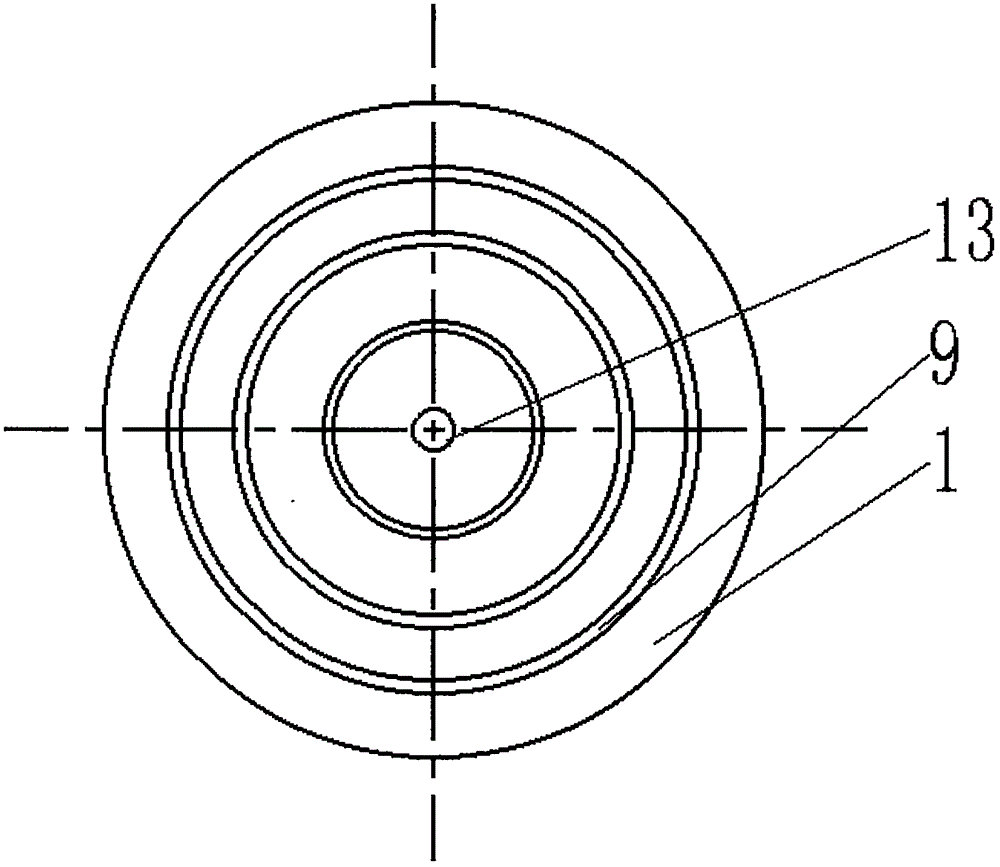

[0015] see Figure 1-3 , a mixer for the production of plastic products, comprising a casing 1, a stirring device 15, a feeding device and a discharging device; the casing 1 is cylindrical, and the lower end surface of the casing 1 is provided with a heating device 2, The heating device 2 is an electric heating device, which can heat the material in the box body 0; the left part of the box body 2 is provided with a feeding device, and the feeding device is composed of a feeding pipe 5, a first electromagnetic valve 4 and a stuffing bin 6 components; the feeding pipe 5 is arranged on the left wall of the box body 4, and the first electromagnetic valve 4 is arranged on the feeding pipe 5, and the first electromagnetic valve 4 is arranged outside the box body 1 for controlling the feeding pipe The opening and closing of 5; the upper part of the feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com