Cam type biological plant oil mixing and homogenizing device

A vegetable oil and cam-type technology, which is applied in mixers, mixers with rotating agitation devices, transportation and packaging, etc., can solve the problems of increasing cost, slow mixing and mixing, and occupying a large volume, so as to increase the mixing quality and reliability High performance and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

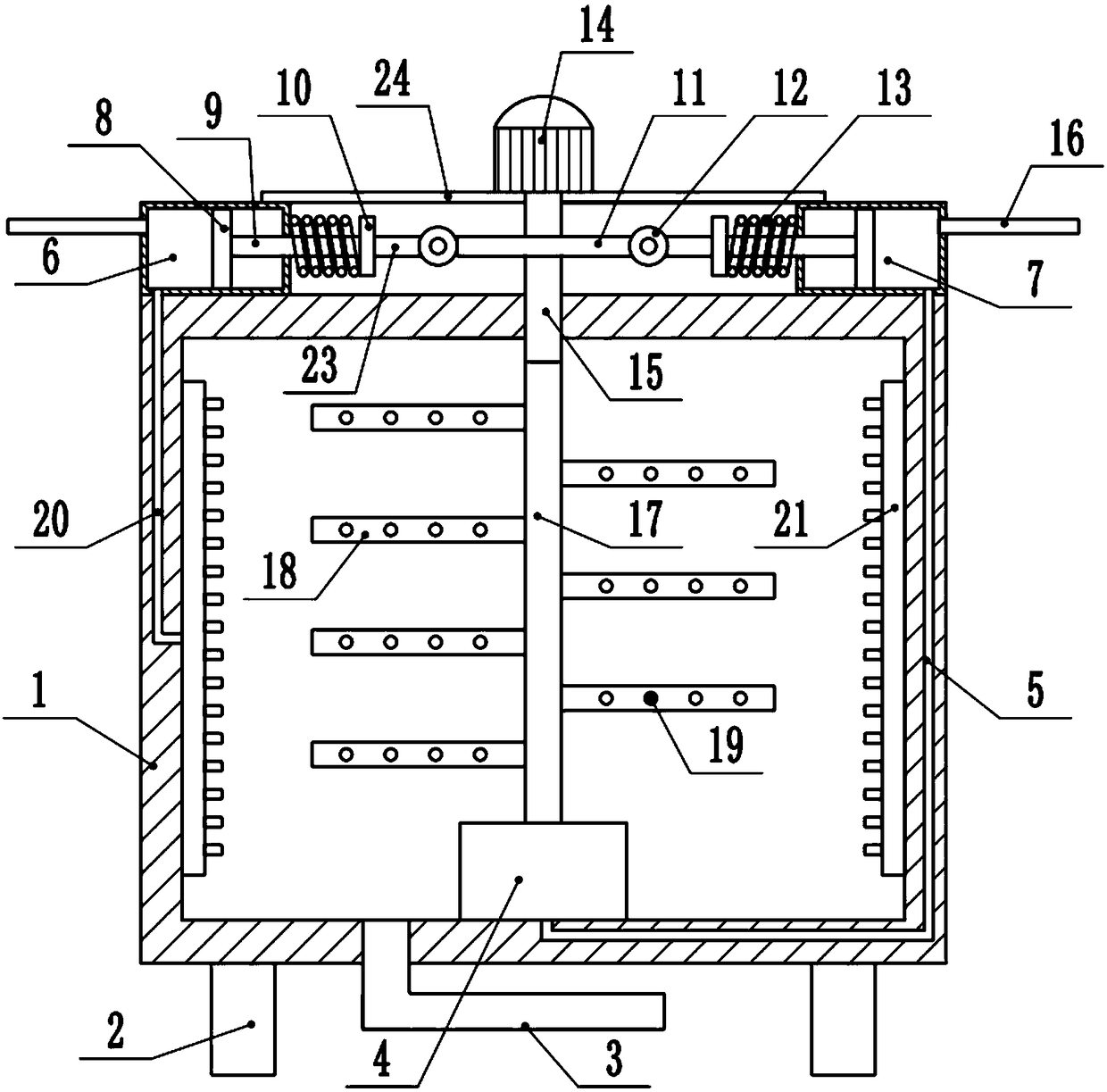

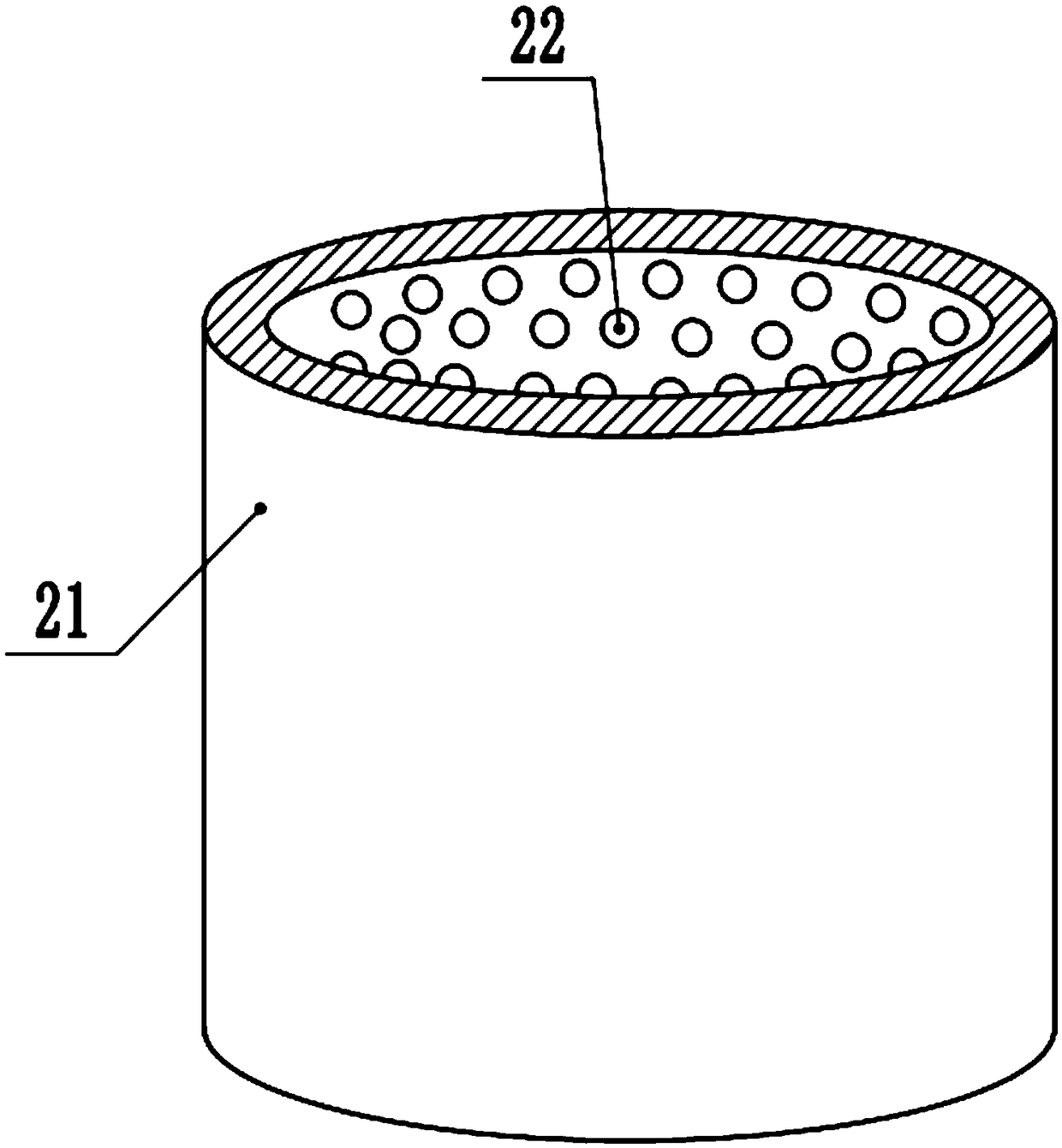

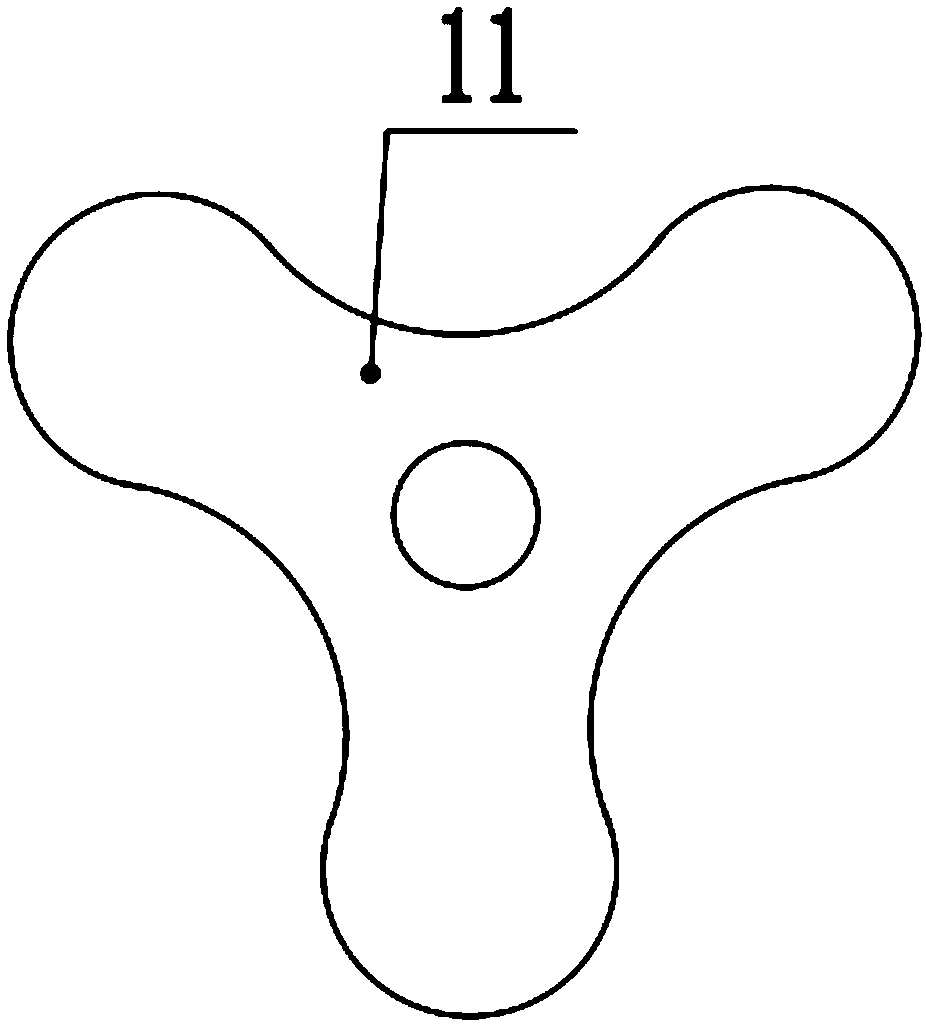

[0028] refer to figure 1 and image 3 , in an embodiment of the present invention, a cam-type bio-vegetable oil mixing and homogenizing device includes a homogenizing barrel 1, a first oil inlet cylinder 6 is installed on the left side of the upper end of the homogenizing barrel 1, and a The second oil inlet cylinder 7, the upper end of the first oil inlet cylinder 6 and the second oil inlet cylinder 7 is equipped with a fixed plate 24, which is used to realize the support and fixation of the hybrid motor 14, and the middle part of the upper end of the fixed plate 24 is equipped with a hybrid motor 14, so The output shaft of the hybrid motor 14 passes through the fixed plate 24 and is connected to the camshaft 15. The first oil inlet cylinder 6 and the second oil inlet cylinder 7 are respectively equipped with a piston 8 inside, and the piston 8 is connected to the inner walls of the two oil inlet cylinders 7. There is an interference fit between them, the piston rod 23 is co...

Embodiment 2

[0031] refer to Figure 4 , in another embodiment of the present invention, in order to increase the sealing effect between the mixing shaft 14 and the oil inlet tank 4, compared with Embodiment 1, the added difference technical feature of this embodiment is that the mixing shaft 14 It is a hollow structure, and the lower end communicates with the oil inlet tank 4 through the sealing ring 25 .

[0032] In the present invention, during work, two oil inlet pipes 16 are stretched into the oil tank that needs to be mixed, and then the mixing motor 14 is started, and the mixing motor 14 drives the camshaft 15 to rotate, and then drives the mixing shaft 15 to rotate synchronously. During the rotation of the shaft 15, the cam 11 is driven to periodically contact the contact ball 12. When in contact, the limit ball 12 will move to the outside, so that the limit rod 23 drives the limit plate 10 to move synchronously. Further, through the action of the piston rod 9, the piston moves ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com