Throwing machine

A technology of drawing machine and machine base, which is applied in the direction of ceramic molding machine, clay processing equipment, auxiliary molding equipment, etc., can solve the problem of single function, and achieve the effect of improving the flexibility of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

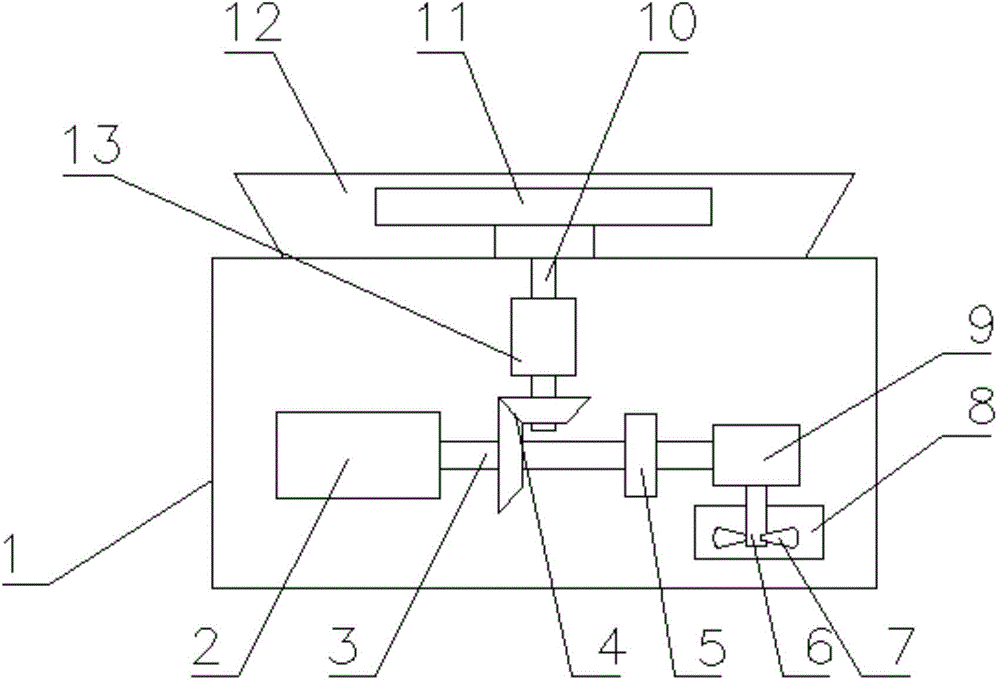

[0012] Such as figure 1 As shown, one embodiment of the present invention is: a drawing machine, including: machine base 1, motor 2, main shaft 3, drawing shaft 10, bevel gear 4, governor 13, drawing turntable 11, gear Disc 12, speed reducer 9, clutch 5, stirring shaft 6, blade 7 and stirring box 8, baffle disk 12 is arranged on the upper end of machine base 1, and baffle disk 12 is trumpet-shaped. The drawing turntable 11 is located in the stopper 12, the motor 2 is fixed inside the machine base 1, the main shaft 3 is connected with the motor 2, the main shaft 3 is set horizontally, and the bottom end of the drawing shaft 10 is connected with the main shaft 3 through a pair of bevel gears 4 , the drawing shaft 10 is perpendicular to the main shaft 3 , the top of the drawing shaft 10 passes through the base 1 , and the top of the drawing shaft 10 is connected with the drawing turntable 11 . The drawing shaft 10 is provided with a governor 13, the top of the stirring shaft 8 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com