Cosmetic raw material barrel transverse conveying mechanism

A technology of horizontal conveying and raw material barrels, which is applied in the directions of conveyors, mechanical conveyors, transportation and packaging to facilitate subsequent processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

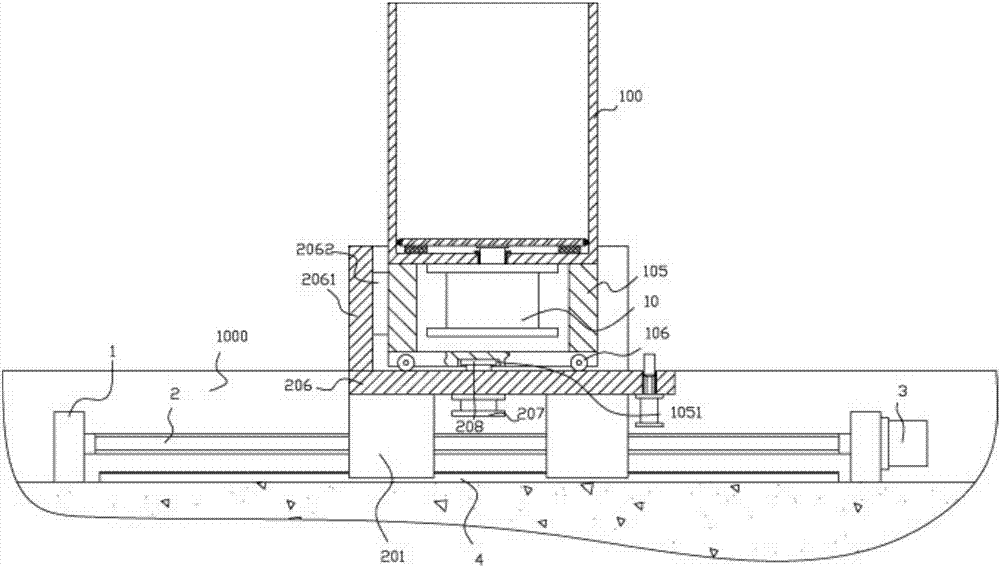

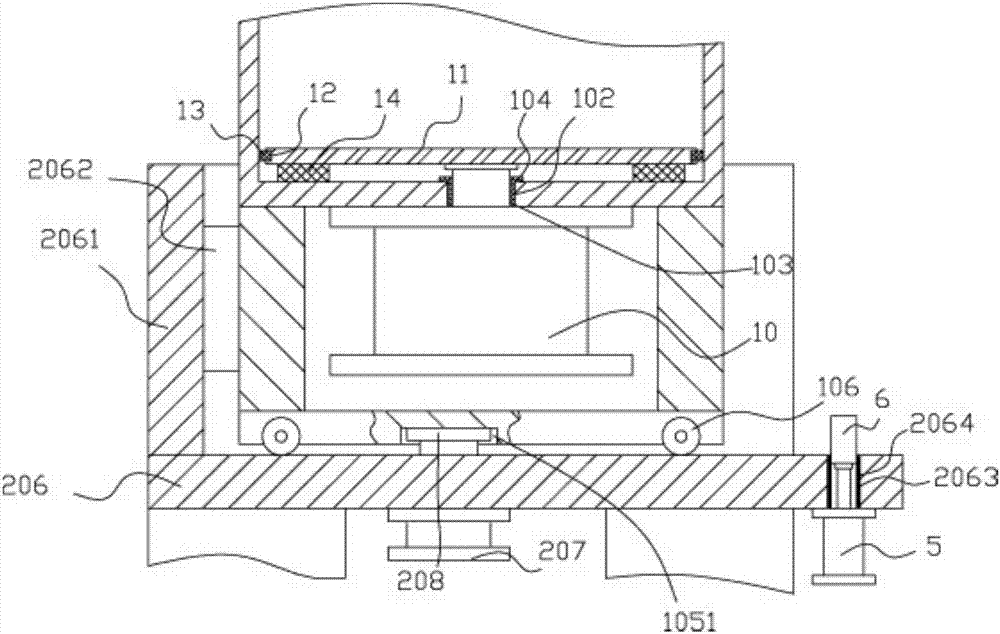

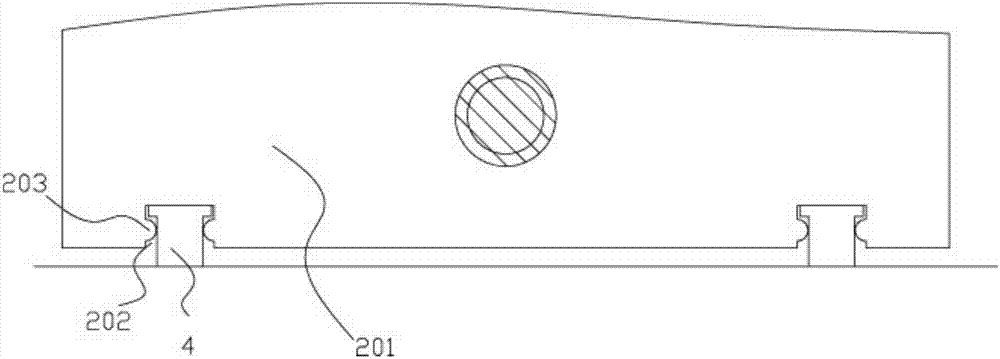

[0024] Example: see Figure 1 to Figure 3 As shown, a cosmetic raw material bucket lifts a horizontal conveying mechanism, including a ground installation groove 1000, a main barrel body 100 and a placement frame 206, and the left and right ends of the ground installation groove 1000 are fixed with an adjustment plate 1 and a horizontal adjustment screw rod 2 The two ends of the two adjustment plates 1 are hinged, and one of the adjustment plates 1 is fixed with a transverse movement motor 3, the output shaft of the transverse movement motor 3 is a spline shaft, and the spline shaft sleeve is inserted at one end of the transverse adjustment screw 2. In the spline hole, the bottom plate of the placement frame 206 is in the ground installation groove 1000, and the left and right sides of the bottom surface of the bottom plate of the placement frame 206 are fixed with lateral moving blocks 201, and the lateral moving blocks 201 are screwed in the horizontal adjustment screw rod 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com