Automatic polishing machine for vertical bamboo flute wall

A grinding machine, automatic technology, applied in the direction of grinding frame, grinding machine parts, machine tools suitable for grinding workpiece edges, etc. The effect of uniform grinding, reduced workload and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

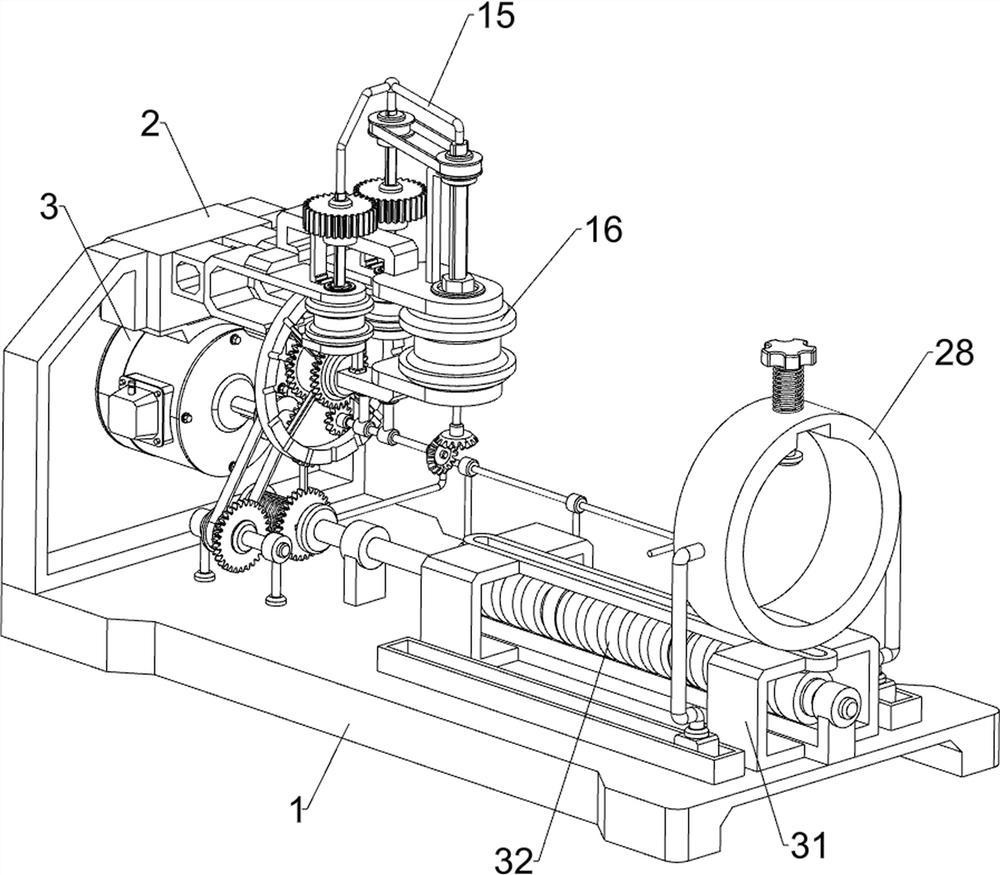

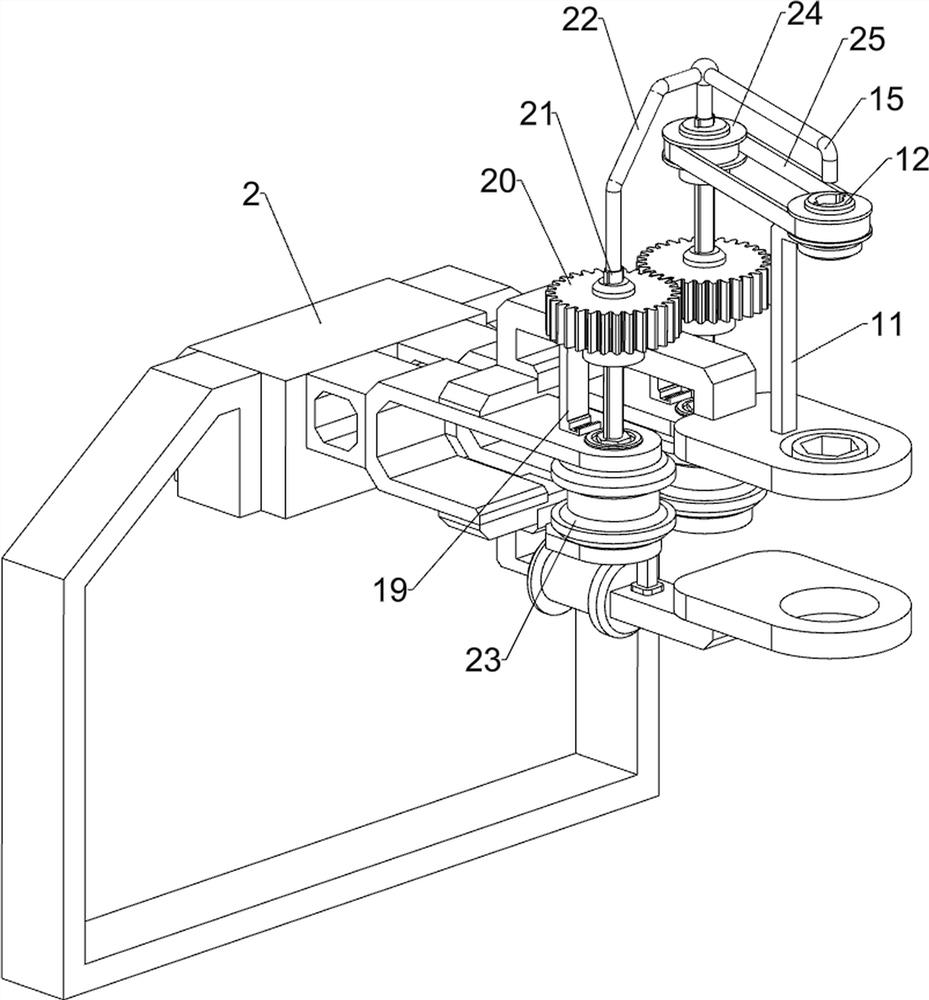

[0025] A flute wall automatic grinding machine, such as Figure 1-4 As shown, it includes a base 1, a mounting frame 2, a power component, a flute wall grinding component and a corner grinding component. The upper left side of the base 1 is fixed with a mounting frame 2 through bolts. 2 is also provided with a flute wall grinding assembly, and an edge grinding assembly is provided between the mounting frame 2 and the flute wall grinding assembly.

[0026] When using this device to polish the flute wall at the blow hole, first control the power component to start working, the power component will drive the flute wall grinding component and the corner grinding component to work, and then connect the blow hole of the flute to the flute wall grinding component Get in touch with the edge grinding component, grind the flute wall at the blow hole, control the power component to stop working after finishing the grinding work, and then take the polished flute away for collection.

[0...

Embodiment 2

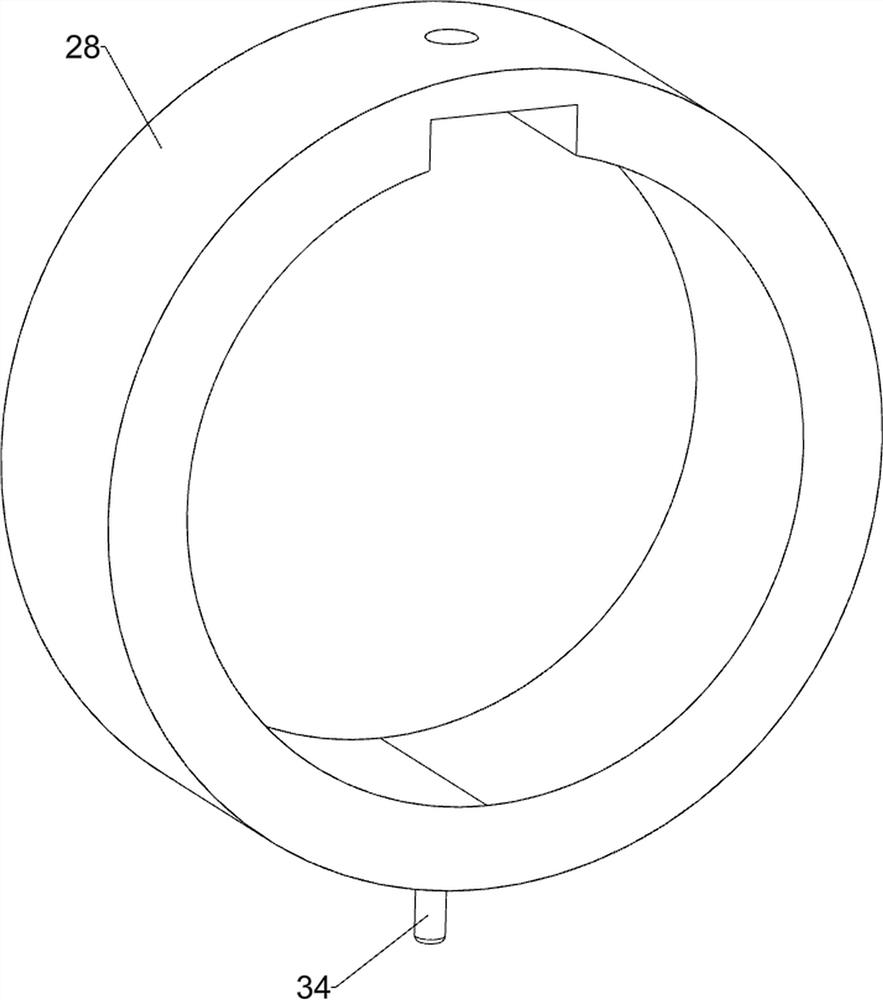

[0034] On the basis of Example 1, such as figure 1 , 5 , shown in 6 and 7, also include slide rail 26, support bar 27, place ring 28, pressure bar 29 and first spring 30, base 1 right front and rear both sides are all fixed with slide rail 26 by bolt, slide rail 26 upper sliding type is provided with support bar 27, is connected with placing ring 28 by bolt between supporting bar 27, and placing ring 28 top sliding type is provided with depression bar 29, is connected with the first spring 30 between pressing bar 29 and placing ring 28 .

[0035] Before polishing the flute, the pressure rod 29 can be pulled up, and the first spring 30 is stretched at this time, and then the flute is placed in the placement ring 28, and the blow hole of the flute is located at the upper left side of the flute. Open the pressure rod 29, at this time the first spring 30 will reset and drive the pressure rod 29 to reset, fix the flute, and then push the placement ring 28 to move to the left alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com