Steel bar specified-length cutting equipment for house building

A technology for specifying the length and cutting equipment, applied in the direction of mechanical equipment, engineering safety devices, etc., can solve the problems of non-adjustable effective length of steel bars, inability to carry out automatic transportation, inability to adapt to flexible use of construction projects, etc., to prevent splashing around and facilitate Collection, good effect of cutting work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

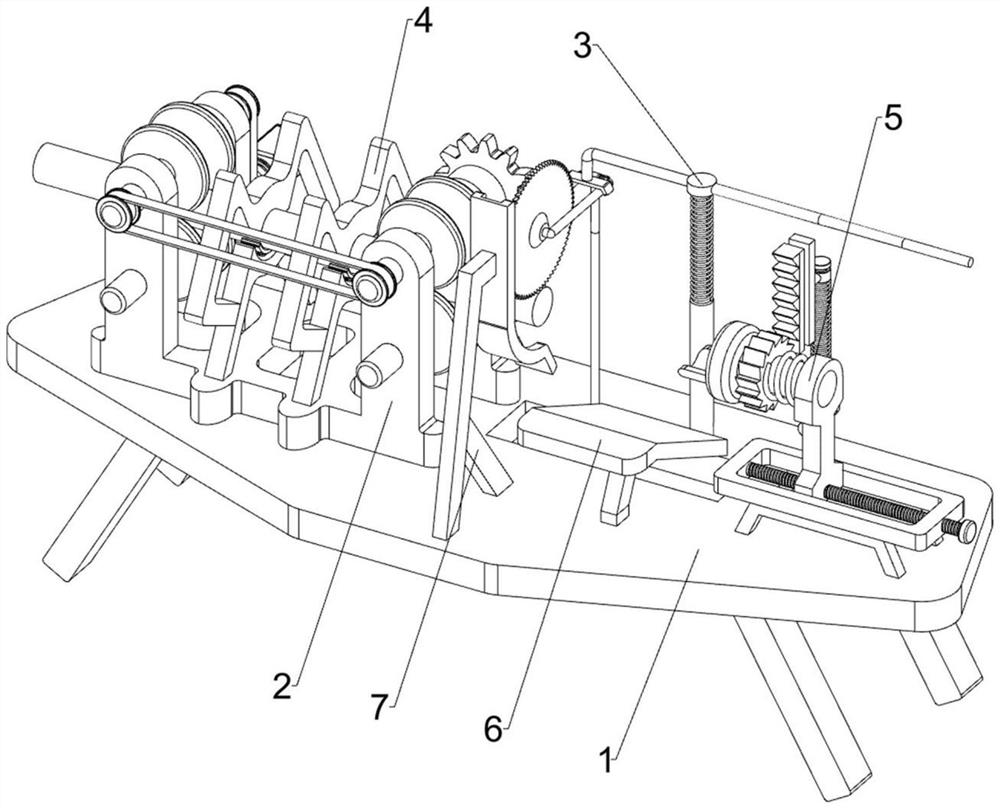

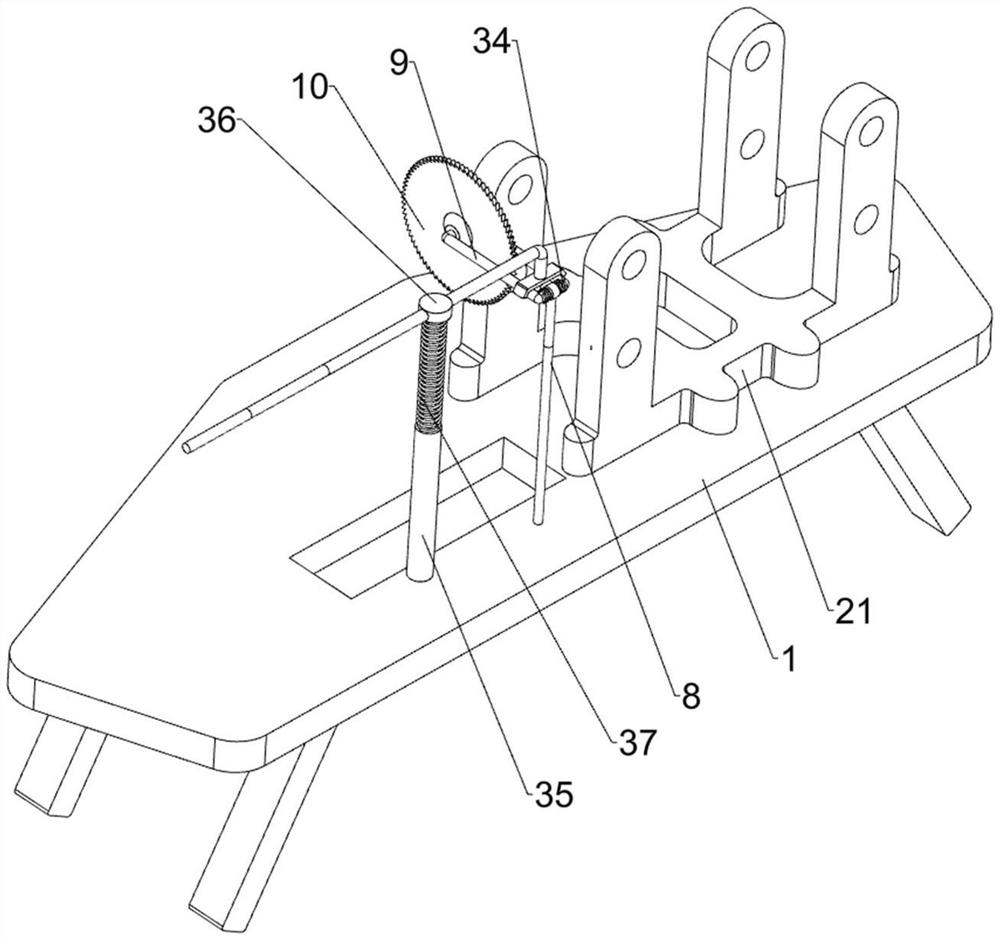

[0062] A device for cutting steel bars to a specified length for building construction, such as figure 1 with image 3 As shown, it includes a base 1, a transmission mechanism 2, a pressing mechanism 3, a mounting column 8, a mounting rod 9 and an electric cutting wheel 10, a pressing mechanism 3 is provided in the middle of the top of the base 1, and a transmission mechanism is provided on the left side of the top of the base 1 2. A mounting column 8 is provided on the rear side of the top of the base 1, a mounting rod 9 is installed on the mounting column 8 in a rotating manner, and an electric cutting wheel 10 is provided on the front side of the mounting rod 9.

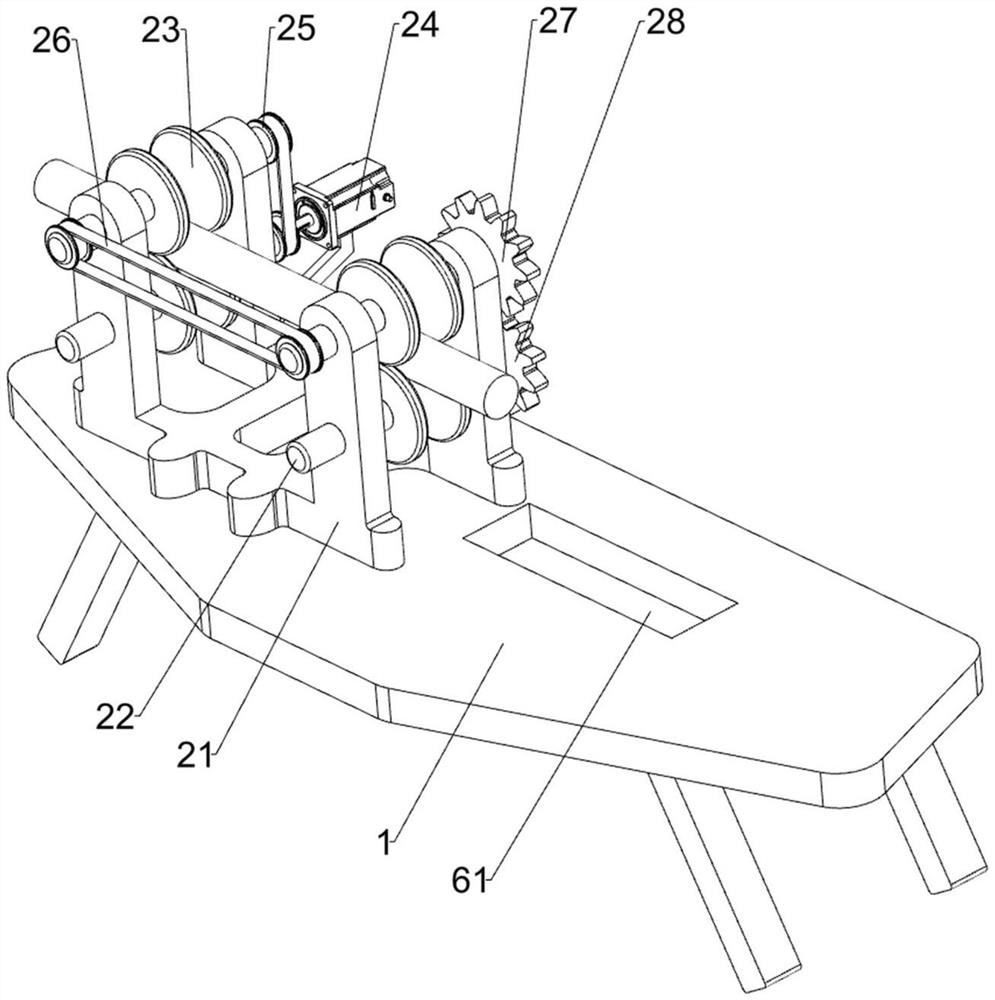

[0063] Such as figure 2 As shown, the transmission mechanism 2 includes a mounting frame 21, a first transmission wheel 22, a second transmission wheel 23, a servo motor 24, a first belt 25, a second belt 26, a first full gear 27 and a second full gear 28, Base 1 top left side is provided with mounting frame 21...

Embodiment 2

[0067] On the basis of Example 1, such as Figure 4 with Figure 5 As shown, a buffer mechanism 4 is also included, and the buffer mechanism 4 includes a buffer frame 41, a buffer plate 42, an upper top plate 43, a lower top plate 44, an adjustment plate 45 and a third spring 46, and the left and right sides of the top of the mounting frame 21 are all symmetrical A buffer frame 41 is provided, and a buffer plate 42 is provided on the outside of the buffer frame 41. An upper top plate 43 is connected between the buffer plates 42 on the left and right sides, and a lower top plate 44 is connected between the buffer frames 41 on the left and right sides. 44 is provided with an adjustment plate 45 slidingly, and a third spring 46 is connected between the adjustment plate 45 and the lower top plate 44 .

[0068] In the process of the steel bar moving to the right, the steel bar will be between the upper top plate 43 and the adjustment plate 45, so that the adjustment plate 45 moves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com