Lifting machine for automobile repair

A technology for lifts and automobiles, applied in the directions of lifting vehicle parts, lifting frames, lifting devices, etc., can solve problems such as difficulty in meeting market demands, poor screw transmission lubrication, uneven lifting force, etc., and achieve uniform force. , Low production cost, uniform lifting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

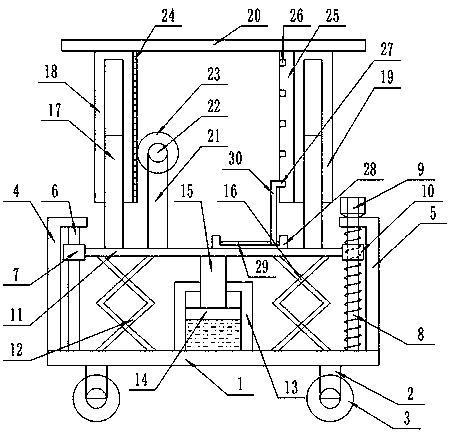

[0023] Such as Figure 1 to Figure 3 As shown, this specific embodiment adopts the following technical solutions: a lift for automobile repair, including a base 1, a pulley mounting rod 2, a pulley 3, a left L-shaped frame 4, a right L-shaped frame 5, a column 6, and a shaft sleeve 7. Lead screw 8, first motor 9, threaded sleeve 10, lifting platform 11, left folding frame 12, hydraulic cylinder 13, sliding disc 14, support column 15 and right folding frame 16; Four pulley installation rods 2 are fixedly connected in an array; a pulley 3 is connected to the end of the pulley installation rod 2; a left L-shaped frame 4 is fixedly connected to the left side of the upper surface of the base 1, and the base 1. A right L-shaped frame 5 is fixedly connected to the right side of the upper surface; a column 6 is fixedly connected to the left L-shaped frame 4, and a lead screw 8 is movably connected to the right L-shaped frame 5; A first motor 9 is fixedly connected to the top of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com