Batch flattening and recycling device for zip-top cans

A recycling device, cans technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of poor extrusion effect, reduced operation volume, and the extrusion environment is not closed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

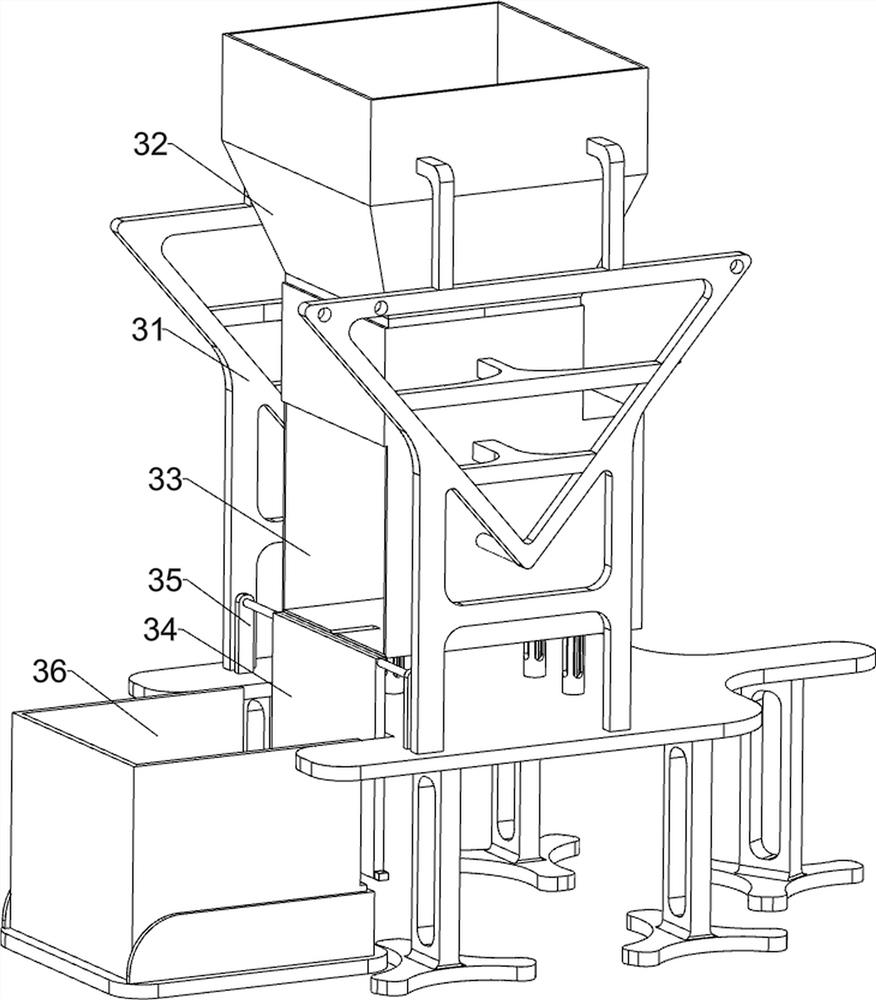

[0055] A batch flattening recovery device for pop cans, such as figure 1 As shown, it includes a base 1, a bottom plate 2, a can flow mechanism 3 and a flattening mechanism 4, which is provided with a base 1 and a bottom plate 2, the bottom plate 2 is located on the left side of the base 1, and the top of the base 1 and the bottom plate 2 is connected with a can flow direction Mechanism 3, the top right side of the base 1 is provided with a flattening mechanism 4.

[0056] The staff can place the cans in the cans flow mechanism 3, start the operation of the flattening mechanism 4 to flatten the cans, after the flattening is completed, the cans can be collected, and after all the flattening is completed, stop the operation of the flattening mechanism 4.

Embodiment 2

[0058] On the basis of Example 1, such as figure 2 and image 3As shown, the can flow direction mechanism 3 includes a support frame 31, a feed frame 32, a working chamber 33, a baffle plate 34, a support seat 35 and a material storage frame 36. The top of the base 1 is symmetrically provided with a support frame 31, and the top of the support frame 31 A feed frame 32 is connected between them, a working chamber 33 is connected between the middle parts of the support frame 31, a support seat 35 is arranged symmetrically on the left side of the top of the base 1, and a baffle plate 34 is rotatably connected between the top of the support seat 35, and the baffle plate 34 and The working cavity 33 is engaged, and the top of the bottom plate 2 is provided with a material storage frame 36 .

[0059] Flattening mechanism 4 includes mounting seat 41, cylinder 42, telescopic push rod 43, pressing plate 44, connecting column 45 and buffer spring 46, base 1 top right side is provided ...

Embodiment 3

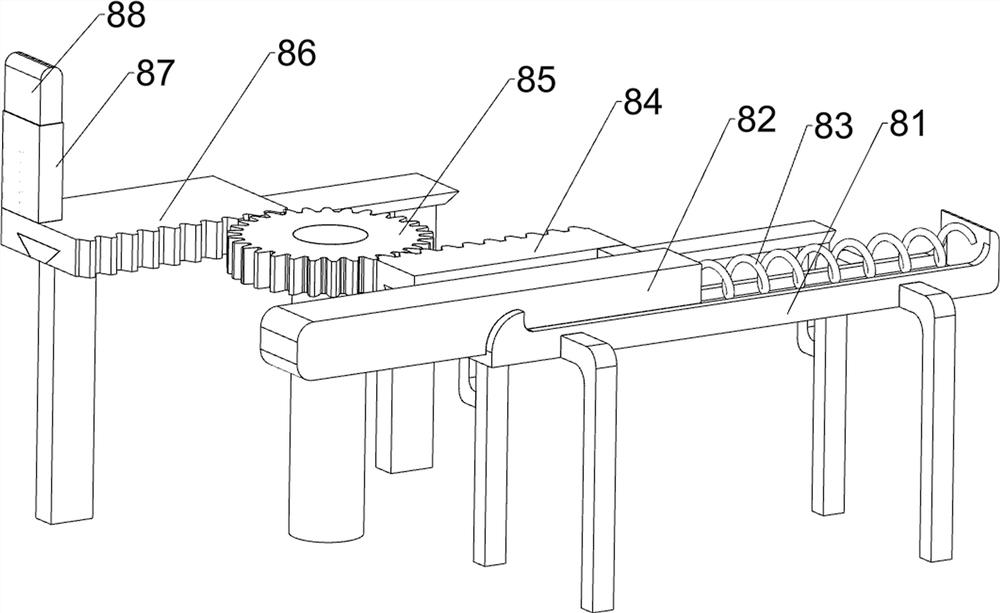

[0062] On the basis of Example 2, such as Figure 4 to Figure 7 As shown, it also includes an automatic switch mechanism 5 for the material retaining plate. The automatic switch mechanism 5 for the material retaining plate includes a connecting rod 51, a first rack 52, a first transmission gear 53 and a movable guide frame 54. On the telescopic rod of the cylinder 42 Connecting rod 51 is connected, and base 1 top front side is provided with movable guide frame 54, and movable guide frame 54 is connected with connecting rod 51 slidingly, and the left side of connecting rod 51 is connected with first rack 52, and on the rotating shaft of baffle plate 34 A first transmission gear 53 is connected, and the first transmission gear 53 meshes with the first rack 52 .

[0063] The expansion rod of the cylinder 42 drives the first rack 52 to move to the left through the connecting rod 51, and the first rack 52 moves to the left through the first transmission gear 53 to drive the baffle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com