High-precision steel plate drilling equipment for orthopedics department

A high-precision, steel plate technology, applied in the direction of drilling/drilling equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of inconvenient adjustment, inconvenient operation, low efficiency of steel plate drilling, etc., to avoid random spilling, Realize the effect of intelligent operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A high-precision steel plate hole-making equipment for orthopedics, such as Figure 1 to Figure 3 As shown, it includes a base 1, a first fixed frame 2, a second fixed frame 3, a cooling plate 4, a sliding glass door 5, a rodless cylinder 6, an electric drill 7, a supporting mechanism 8 and a moving mechanism 9, and the left side of the top of the base 1 There is a first fixed frame 2, the top of the first fixed frame 2 is provided with a cooling plate 4, the front side of the first fixed frame 2 is slidingly provided with a sliding glass door 5, and the left rear side of the upper inner wall of the first fixed frame 2 is provided with a rodless Cylinder 6, an electric drill 7 is provided on the telescopic rod of the rodless cylinder 6, a second fixed frame 3 is provided on the right side of the top of the base 1, a support mechanism 8 is provided at the bottom of the inner wall of the first fixed frame 2, and a moving mechanism is connected to the support mechanism 8 9...

Embodiment 2

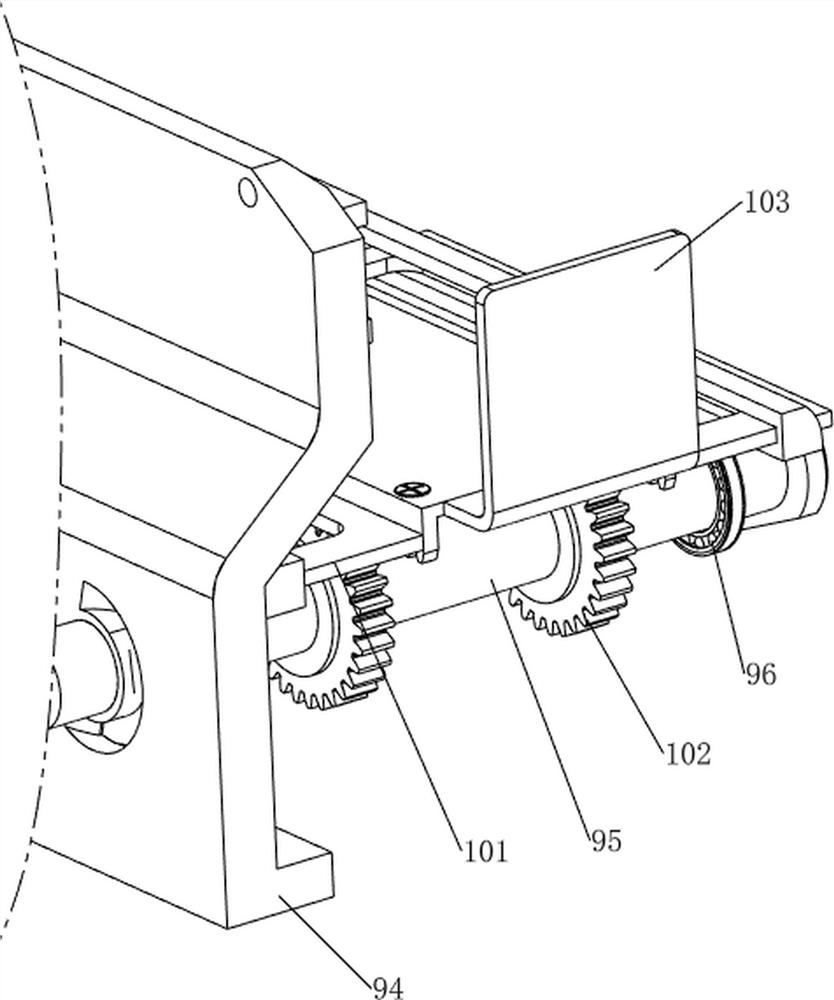

[0036] On the basis of Example 1, such as Figure 4 As shown, a correction mechanism 10 is also included. The correction mechanism 10 includes a second bracket 101, a first full gear 102 and a correction plate 103. The front part of the rotating shaft 95 is provided with the first full gear 102, and the rear side of the fixed splint 93 slides. A second bracket 101 is arranged in the formula, and the second bracket 101 is slidably connected with the sliding splint 94, and the left side of the second bracket 101 is provided with a correction plate 103.

[0037] The staff can drive the rotating shaft 95 to rotate by turning the handle, and the rotating shaft 95 rotates through the first full gear 102 to drive the second support 101 to move to the right, and the second support 101 moves to the right to drive the correction plate 103 to move to the right and fix the splint 93 Cooperate with correcting the steel plate, cooperate with precise drilling, after the drilling is completed...

Embodiment 3

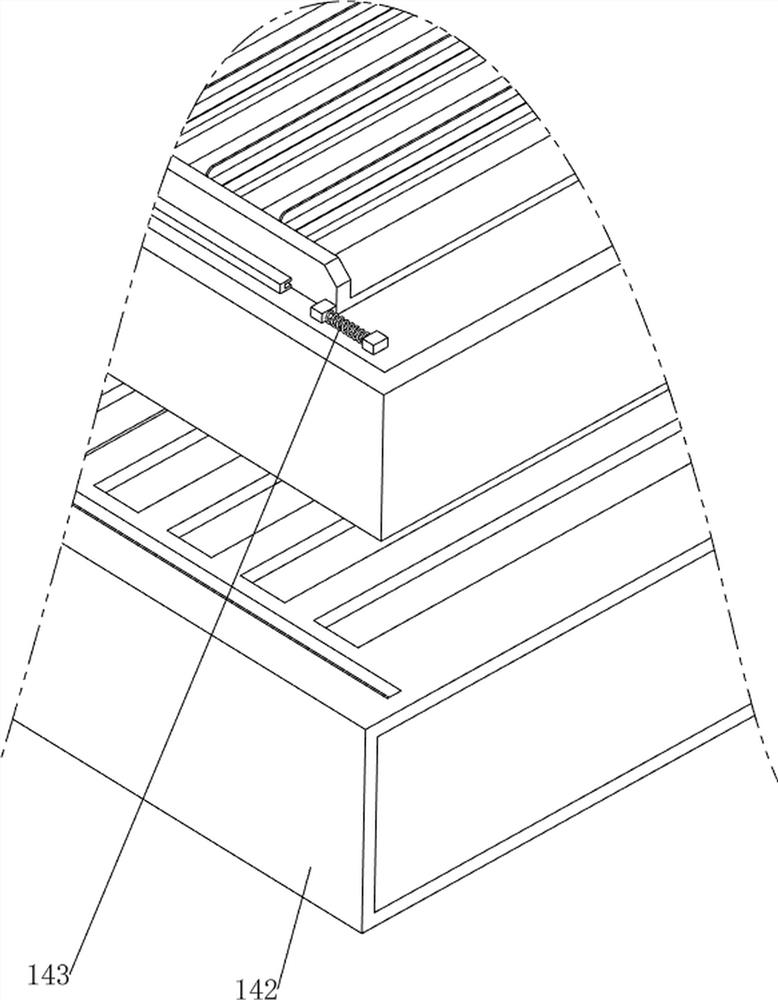

[0039] On the basis of Example 2, such as Figure 5 to Figure 8 As shown, a pushing mechanism 11 is also included, and the pushing mechanism 11 includes a third bracket 111, a worm screw 112, a first rotating rod 113, a second connecting rod 114, a first compression spring 115, a first torsion spring 116, and a ratchet 117 , the first rotating shaft 118, the worm gear 119 and the second full gear 1110, the rear side of the top of the bottom plate 81 is provided with a third support 111, the top of the third support 111 is rotatably provided with a worm screw 112, the right side of the top of the bottom plate 81 is provided with a motor, the motor The output shaft is connected to the right side of the worm screw 112, and the worm screw 112 is provided with a ratchet 117 in the left side rotation type, and the first torsion spring 116 is connected between the ratchet tooth 117 and the worm shaft 112, and the left side rotation type of the worm screw 112 is provided with a first r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com