Automatic pipe inserting device for surface air cooler box

A surface cooler and automatic technology, which is applied in the field of automatic intubation device of the surface cooler box, can solve the problems of low work efficiency and easy injury to the hands of the staff, and achieve the effects of convenient operation, saving manpower, and simplifying the transportation operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

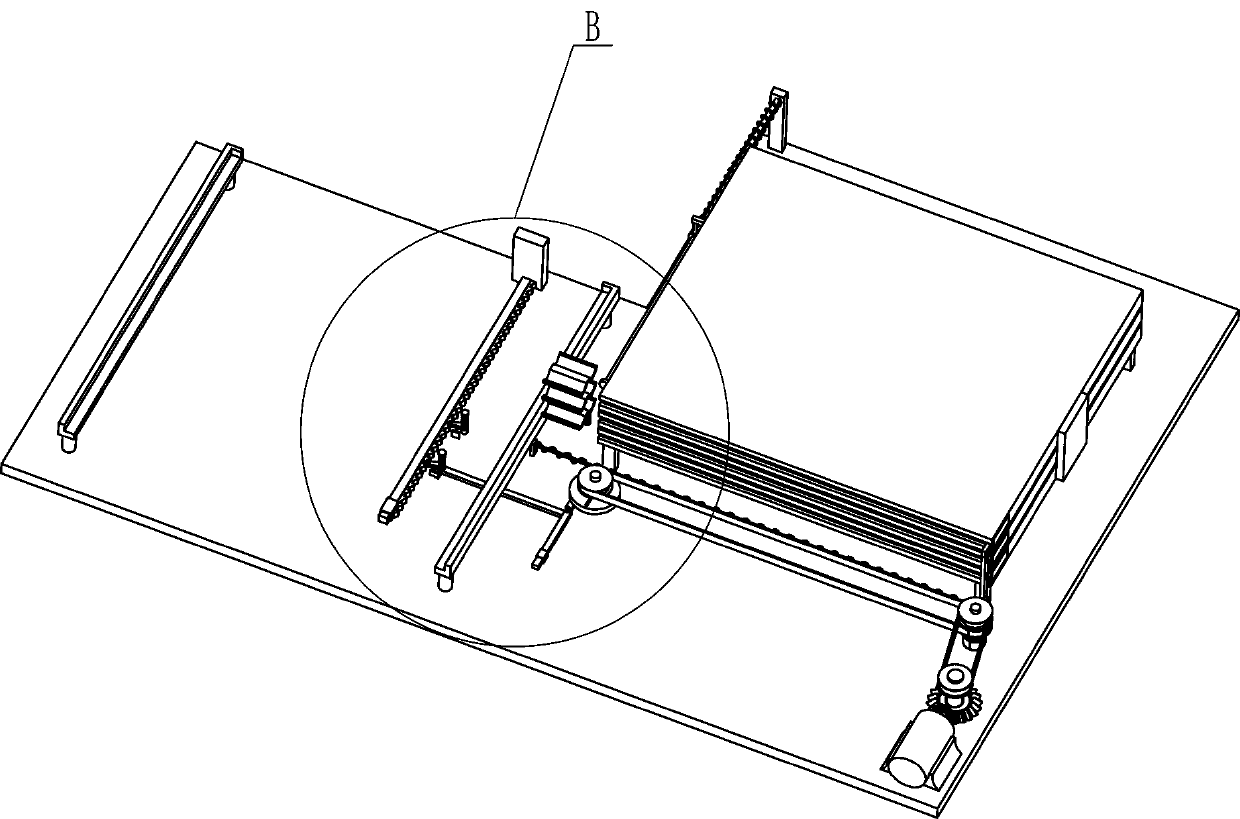

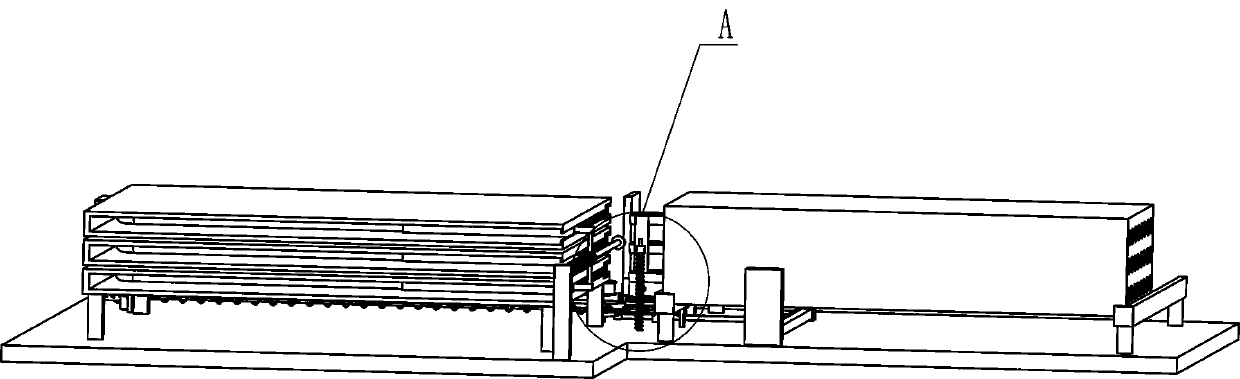

[0030] An automatic intubation device for a surface cooler box, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 7 and Figure 8 As shown, it includes a base plate 1, a motor 2, a feeding box 3, a first connecting plate 4, a push assembly 6 and a drive assembly 7, the motor 2 is installed on the top front left of the base plate 1, and the right front portion of the base plate 1 There are three feeding boxes 3 for storing U-shaped copper pipes 301 from bottom to top, each feeding box 3 has a chute 302 on the left wall, and a first connecting plate is connected between the front walls of the feeding boxes 3 4. There is an opening 5 on the left side of the front wall of each feeding box 3, and the opening 5 communicates with the chute 302. The driving assembly 7 is installed on the left side of the front part of the bottom plate 1, and the driving assembly 7 is located between the motor 2 and the feeding box 3. Between, the driving assembly 7 is connected with t...

Embodiment 2

[0039] On the basis of Example 1, such as Figure 4 , Figure 5 , Figure 6 and Figure 10 As shown, it also includes a turntable 11, a fixed rod 1101, a first push plate 12, a first support plate 13, a fourth spring 14, a first limit block 15, a torsion spring 16, a special-shaped connecting rod 17, and a first guide sleeve 18. Second connecting rod 19, connecting rod 20, driving pawl 21, reverse locking pawl 2101, second limit block 22, support block 23, fifth spring 24, second guide sleeve 25, ratchet bar 26 and The second push block 27, the rotating disk 11 is installed in the middle part of the vertical rod 77, and the middle part of the vertical rod 77 is connected with a fixed rod 1101. The first push plate 12 and the first support plate 13 are connected in a rotational manner, the first support plate 13 is located under the side of the first push plate 12, and the end of the first support plate 13 is in contact with the side wall of the first push plate 12 A fourth...

Embodiment 3

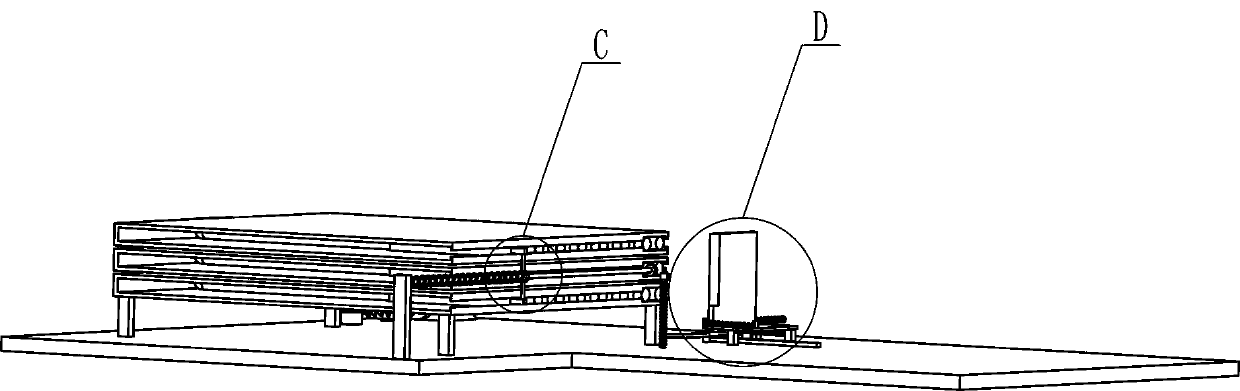

[0042] On the basis of Example 2, such as figure 1 , Figure 7 and Figure 9 As shown, it also includes a second support plate 28, a second push plate 29, a fourth guide rod 30, a second block 31, a sixth spring 32, a slide block 33, a second fixed block 34, and a first slide bar 35 , the seventh spring 36, the third fixed block 37, the second slide bar 3701, the third push block 38, the eighth spring 39, the first guide wheel 40, the second guide wheel 41 and the stay cord 42, the front of the middle part of the bottom plate 1 The second support plate 28 is installed on the side, and the second support plate 28 is positioned at the front side of the front side L-shaped slide rail 9, and the bottom wall of the second support plate 28 is positioned at the top of the connecting rod 20, and the top of the second support plate 28 is on the right side. A second fixed block 34 is arranged symmetrically on the front and rear sides, and a first slide bar 35 is installed between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com