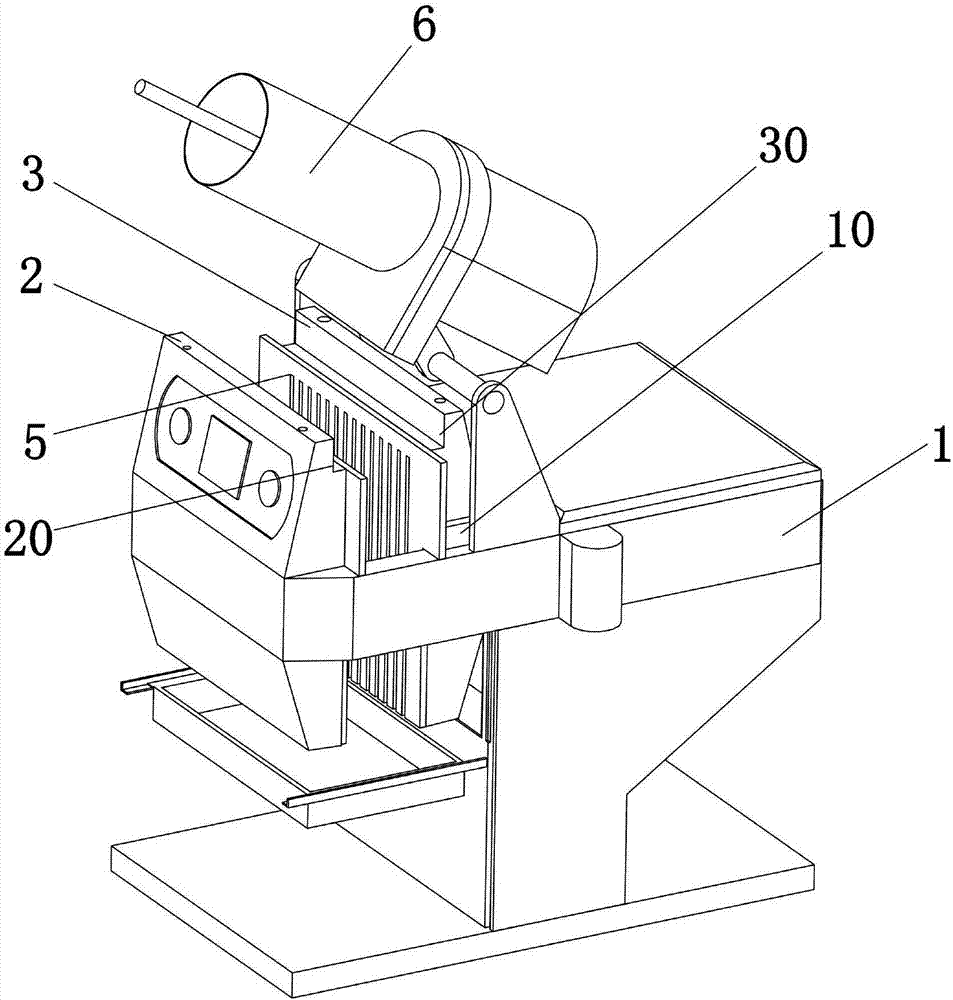

Pressing and filtering device for cold pressing juicer

A fruit juice machine and cold-pressing technology, which is applied in the field of filter press devices for cold-pressed fruit juice machines, can solve problems such as insufficient extrusion, easy splashing of juice, and high degree of oxidation of juice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

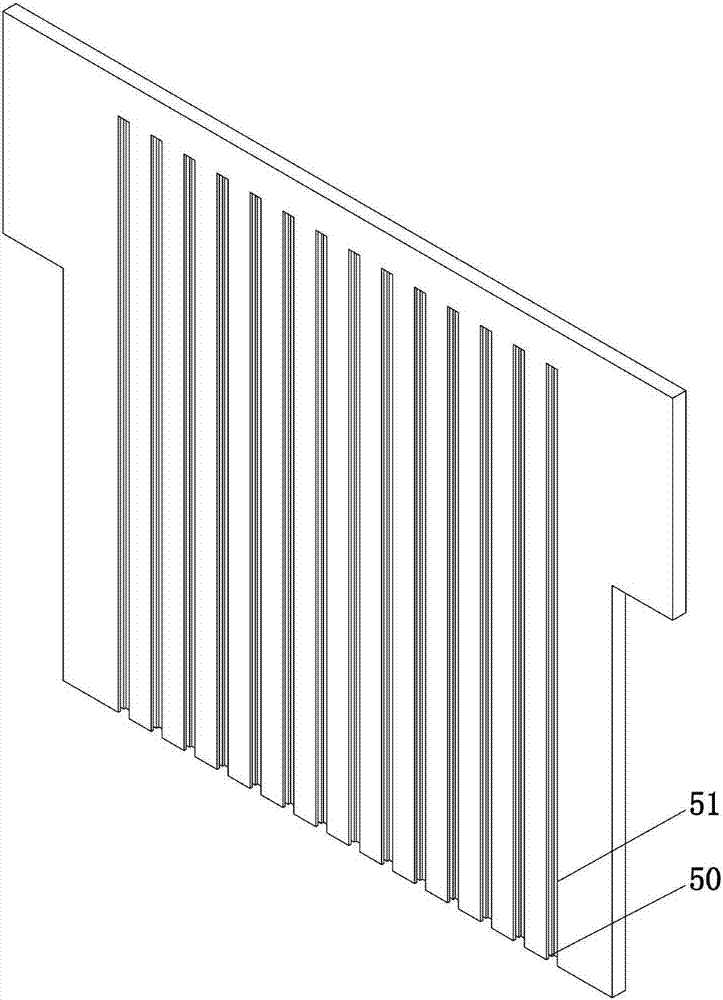

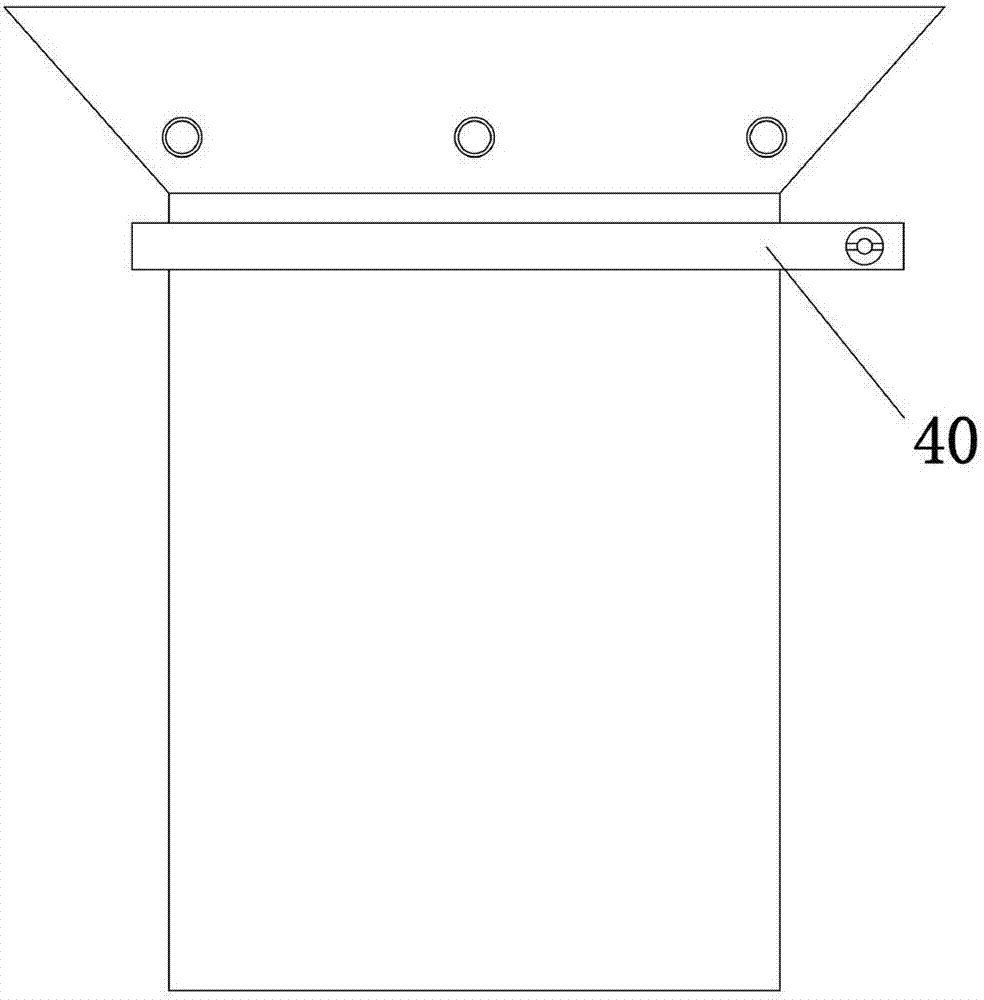

[0029] Embodiment 2, in another scheme, refer to the attached Figure 5 and 6 , the fixed platen 2 is provided with an extrusion groove 21; the movable platen 3 is provided with an extrusion protrusion 31; the extrusion protrusion 31 is matched with the extrusion groove 21, and the filter bag 4 is placed in the extrusion The inside of the groove 21 is squeezed by the extrusion protrusion 31 . A diversion groove 310 is provided on the extrusion protrusion 31 for diverting juice. The diversion groove 310 is annular, and the fruit juice can flow down along the annular diversion groove 310. The juice that flows down can flow out from the diversion port 311 provided at the lower end of the diversion groove 310 and enter the juice collection container. The diversion ports 311 of the diversion grooves 310 are arranged in concentric circles, so that the diversion grooves 310 can collect fruit juice to the greatest extent.

[0030] In order to solve the above-mentioned technical pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com