Automatic aseptic cold loading production technology

A technology of aseptic cold filling and production process, which is applied in juice extraction, food processing, food science and other directions, can solve the problems of nutrient destruction and poor juice flavor, and achieve the effects of less loss of nutrients, easy operation and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

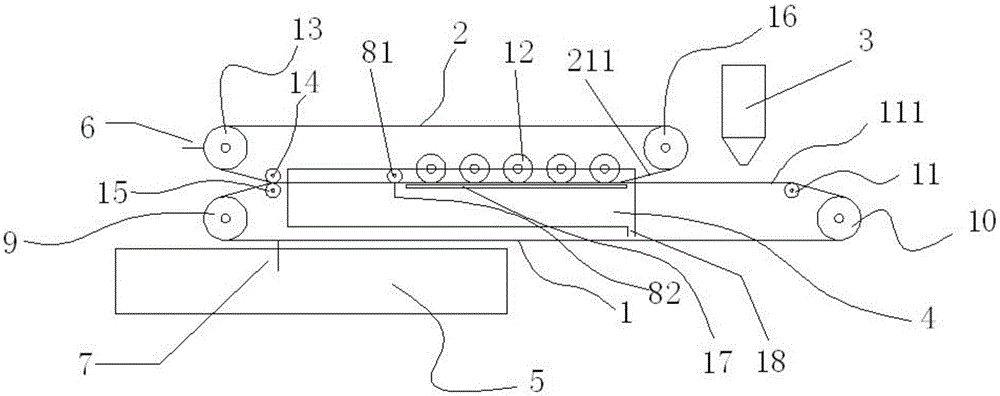

Image

Examples

Embodiment 1

[0036] According to the content provided by the present invention, the inventor has prepared a canned fruit juice drink 1, wherein the proportioning and preparation process of each component are as follows:

[0037] A) Cleaning and disinfection of equipment and facilities;

[0038] B) Pick fresh fruit and pick out rotten fruit; detect the following indicators of fresh fruit: sugar content, acidity, fruit size, variety, pesticide residues, impurities, heavy metals; select fresh fruit that meets the standard;

[0039] C) The first cleaning: Manually pour the selected fresh fruit into the surf fruit washing machine equipped with sterile water, which will be automatically cleaned by the surf fruit washing machine for two minutes, and then transported to the next process through the lifting bucket;

[0040] D) The second cleaning (ozone surfing cleaning and disinfection): the ozone generated by the ozone machine enters the blower, and is blown by the blower to the surfing machine e...

Embodiment 2

[0053] According to the content provided by the present invention, the inventor has made a canned fruit juice drink 2, wherein the proportioning and preparation process of each component are as follows:

[0054] A) Cleaning and disinfection of equipment and facilities;

[0055] B) Pick fresh fruit and pick out rotten fruit; detect the following indicators of fresh fruit: sugar content, acidity, fruit size, variety, pesticide residues, impurities, heavy metals; select fresh fruit that meets the standard;

[0056] C) The first cleaning: Manually pour the selected fresh fruit into the surf fruit washing machine equipped with sterile water, which will be automatically cleaned by the surf fruit washing machine for three minutes, and then transported to the next process through the lifting bucket;

[0057] D) The second cleaning (ozone surfing cleaning and disinfection): the ozone generated by the ozone machine enters the blower, and is blown by the blower to the surfing machine equip...

Embodiment 3

[0070] According to the content provided by the present invention, the inventor has prepared a canned fruit juice drink 3, wherein the proportioning and preparation process of each component are as follows:

[0071] A) Cleaning and disinfection of equipment and facilities;

[0072] B) Pick fresh fruit and pick out rotten fruit; detect the following indicators of fresh fruit: sugar content, acidity, fruit size, variety, pesticide residues, impurities, heavy metals; select fresh fruit that meets the standard;

[0073] C) The first cleaning: Manually pour the selected fresh fruit into the surf fruit washing machine equipped with sterile water, which will be automatically cleaned by the surf fruit washing machine for two minutes, and then transported to the next process through the lifting bucket;

[0074] D) The second cleaning (ozone surfing cleaning and disinfection): the ozone generated by the ozone machine enters the blower, and is blown by the blower to the surfing machine e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com