Walnut kernel peeling and debittering method

A walnut kernel and ultrasonic-assisted technology are applied in the fields of removing astringency and peeling walnut kernels, which can solve the problems of affecting the taste of walnut kernels, destroying nutrients, and being difficult to eliminate with lye, achieving good peeling effect, increasing the loss of nutrients, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

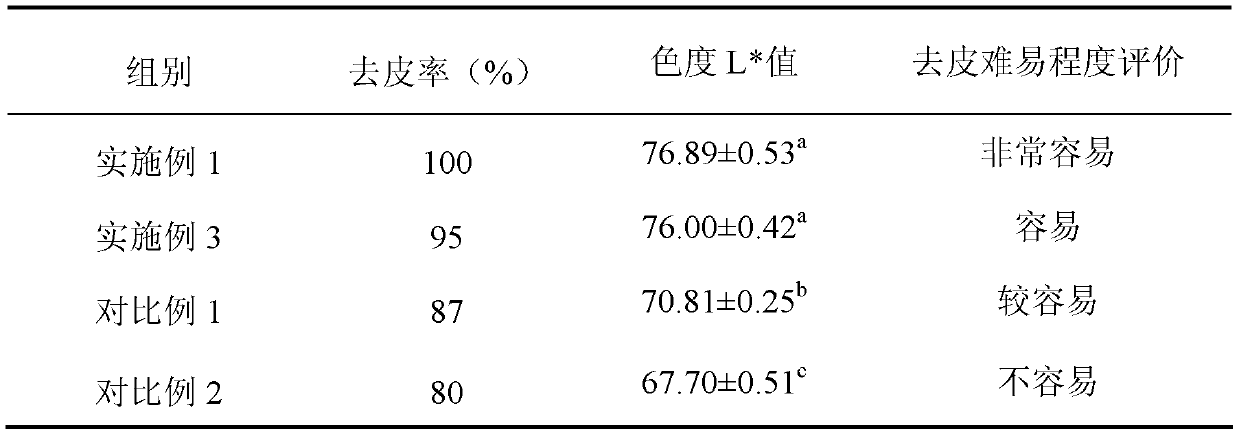

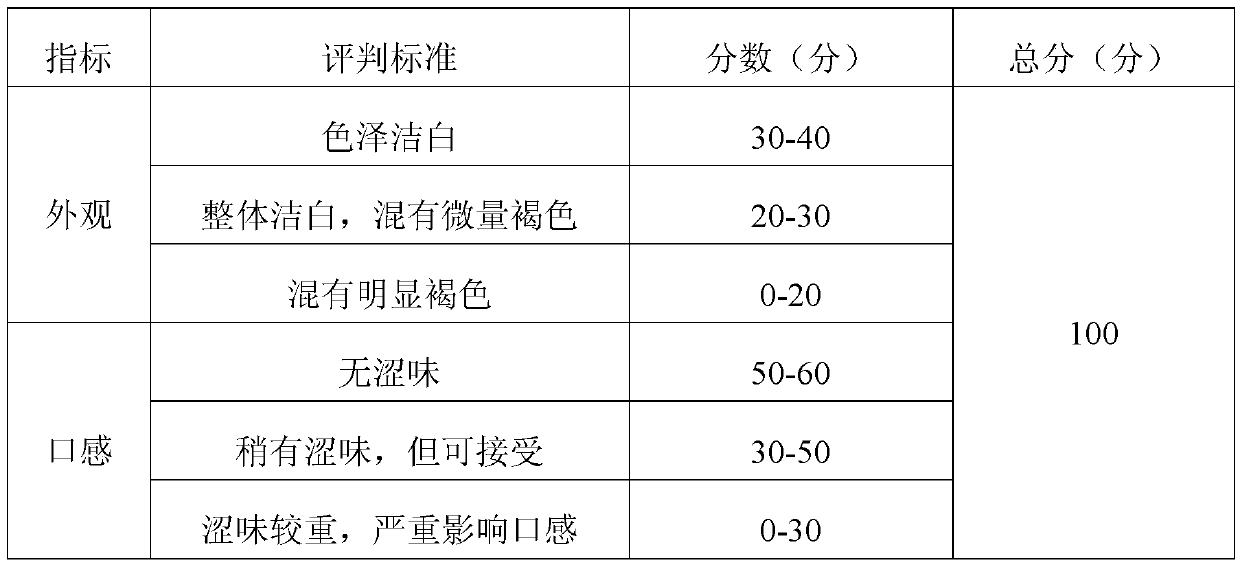

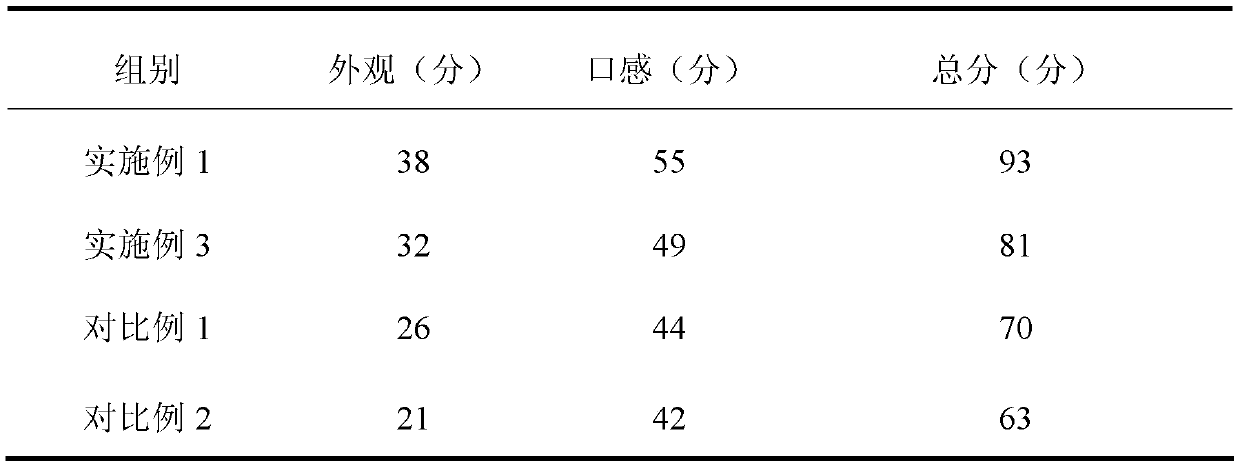

Examples

Embodiment 1

[0029] A method for peeling walnut kernels and removing astringency, comprising the steps of:

[0030] (1) Pretreatment of walnut kernels: Put the walnut kernels into a plasma activation machine for activation treatment. Under the conditions of a pressure of 50Pa and an activation power of 100W, they are treated with plasma carbon dioxide gas for 180s, and the gas flow rate during the treatment process is 0.8L. / min to get pretreated walnut kernels.

[0031] (2) Graded ultrasound-assisted peeling:

[0032] S1, preparation of peeling and astringent agent: get 0.3% quicklime, 0.4% edible alkali, 0.01% sodium diacetate, 0.04% xanthan gum, 0.02% polyvinylpyrrolidone, 0.02% glycerin by weight percentage, and the balance is water , mix evenly to obtain a mixed solution, adjust the pH of the mixed solution to 12.5 with food-grade NaOH, and obtain peeling and astringent-removing agent I;

[0033] S2. The first level of ultrasonic-assisted peeling: Put the peeling and astringent agen...

Embodiment 2

[0039] A method for peeling walnut kernels and removing astringency, comprising the steps of:

[0040](1) Pretreatment of walnut kernels: Put the walnut kernels into a plasma activation machine for activation treatment. Under the conditions of a pressure of 60Pa and an activation power of 150W, they are treated with plasma nitrogen gas for 120s, and the gas flow rate during the treatment process is 1.0L. / min to get pretreated walnut kernels.

[0041] (2) Graded ultrasound-assisted peeling:

[0042] S1, preparation of peeling and astringent agent: take 0.2% quicklime, 0.5% edible alkali, 0.02% sodium diacetate, 0.03% xanthan gum, 0.03% polyvinylpyrrolidone, 0.01% glycerin by weight percentage, and the balance is water , mix evenly to obtain a mixed solution, adjust the pH of the mixed solution to 13 with food-grade NaOH, and obtain peeling and astringent-removing agent I;

[0043] S2. The first level of ultrasonic-assisted peeling: Put the peeling and astringent agent I into...

Embodiment 3

[0049] A method for peeling walnut kernels and removing astringency, comprising the steps of:

[0050] (1) Pretreatment of walnut kernels: soak walnut kernels in clean water for 0.5h, drain the water for later use;

[0051] (2) Graded ultrasound-assisted peeling:

[0052] S1, preparation of peeling and astringent agent: get 0.3% quicklime, 0.4% edible alkali, 0.02% sodium diacetate, 0.03% xanthan gum, 0.03% polyvinylpyrrolidone, 0.02% glycerin by weight percentage, and the balance is water , mix evenly to obtain a mixed solution, adjust the pH of the mixed solution to 12.3 with food-grade NaOH, and obtain the peeling and astringent-removing agent I;

[0053] S2. The first level of ultrasonic-assisted peeling: put the peeling and astringent agent I into the ultrasonic instrument, turn on the machine and heat up to 67°C, put the walnut kernels into the peeling and astringent agent I, and submerge it below the liquid surface. Ultrasonic treatment for 1 min at 67°C and ultrasoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com