Juicer and filter screen applied by same

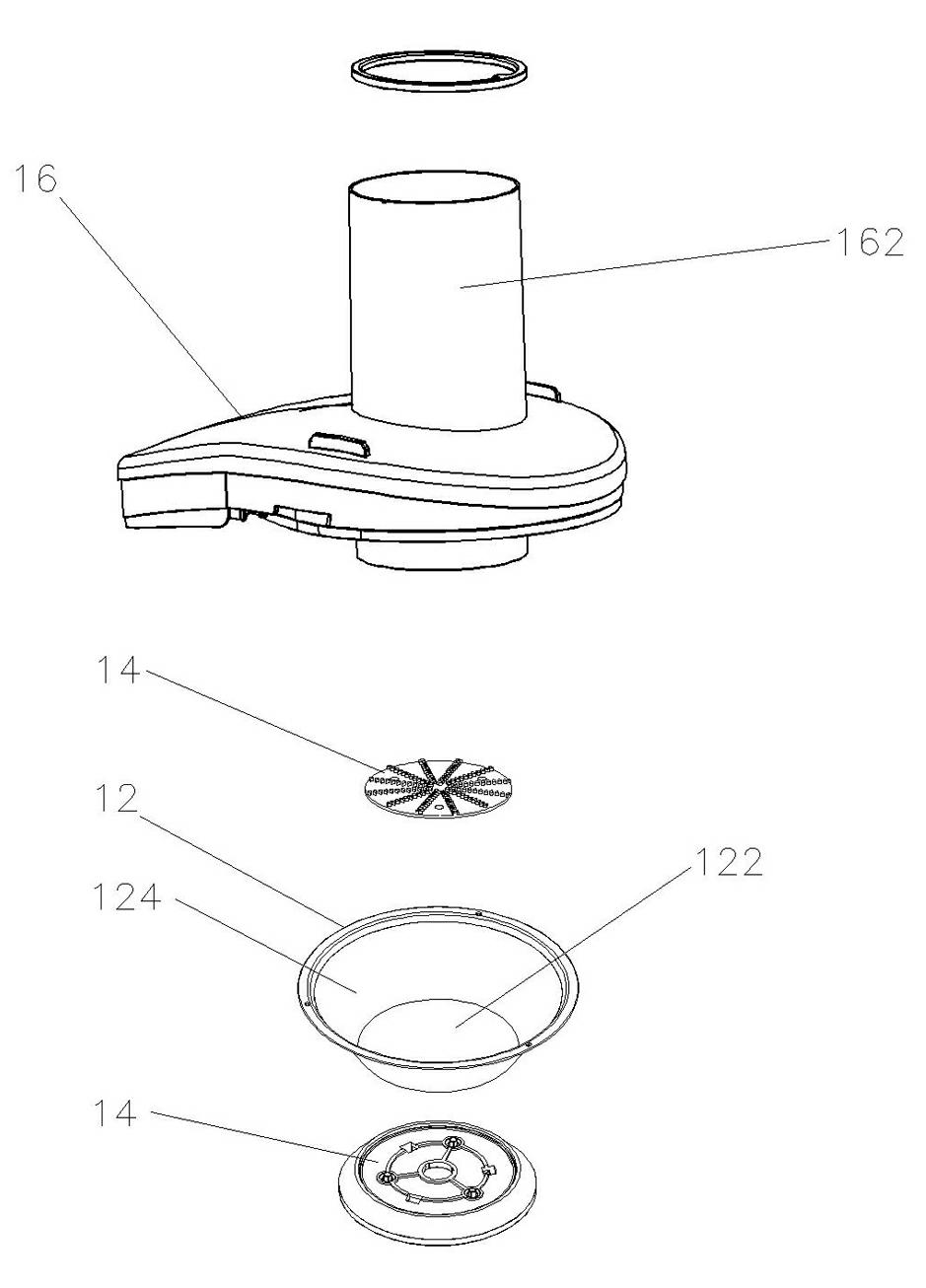

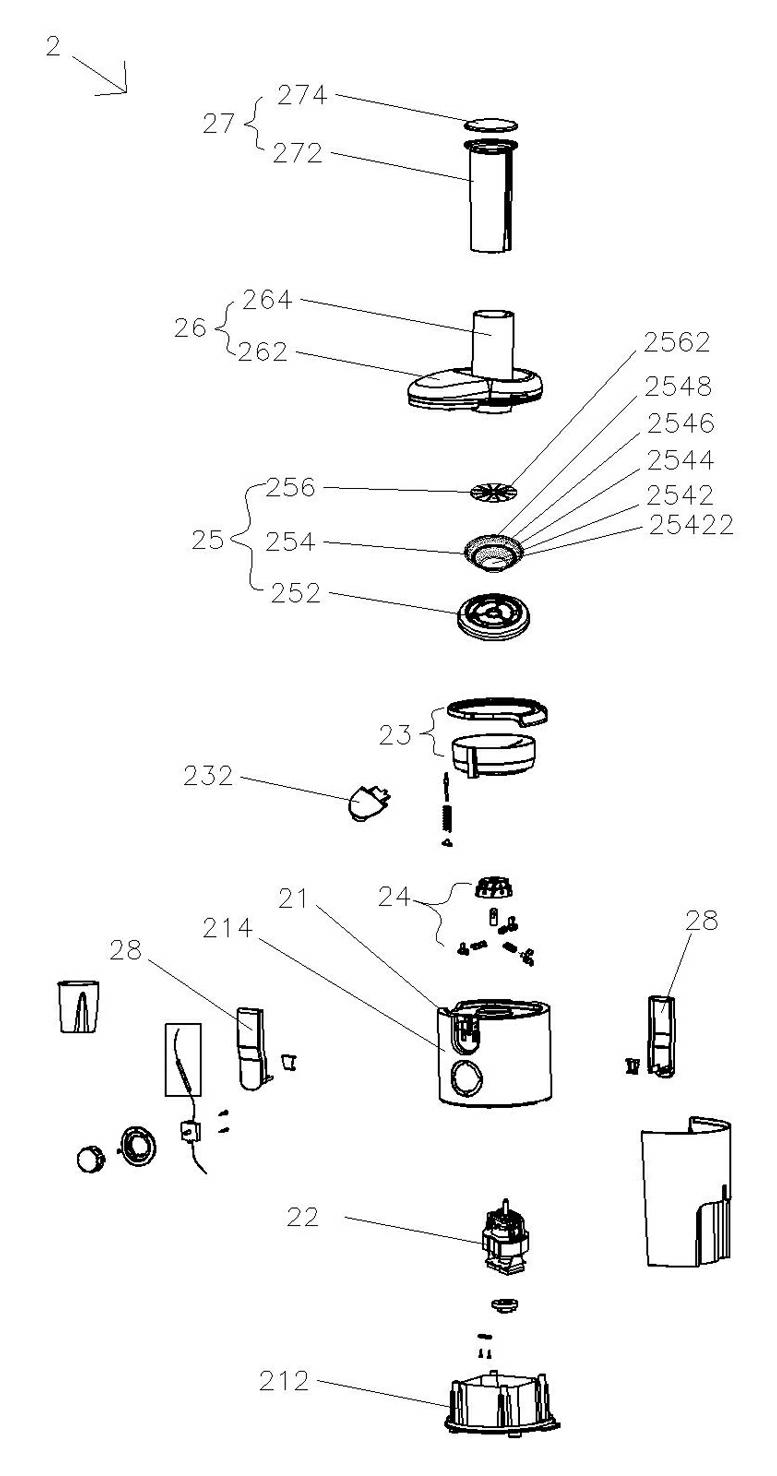

A technology of a juicer and a filter screen is applied in the field of a filter screen and a juicer using the filter screen, which can solve the problems of low juicing rate, non-dry fruit residue, low juicing efficiency, etc. The effect of increasing the area and improving the efficiency of juicing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0062] The first embodiment of the present invention has the following beneficial effects:

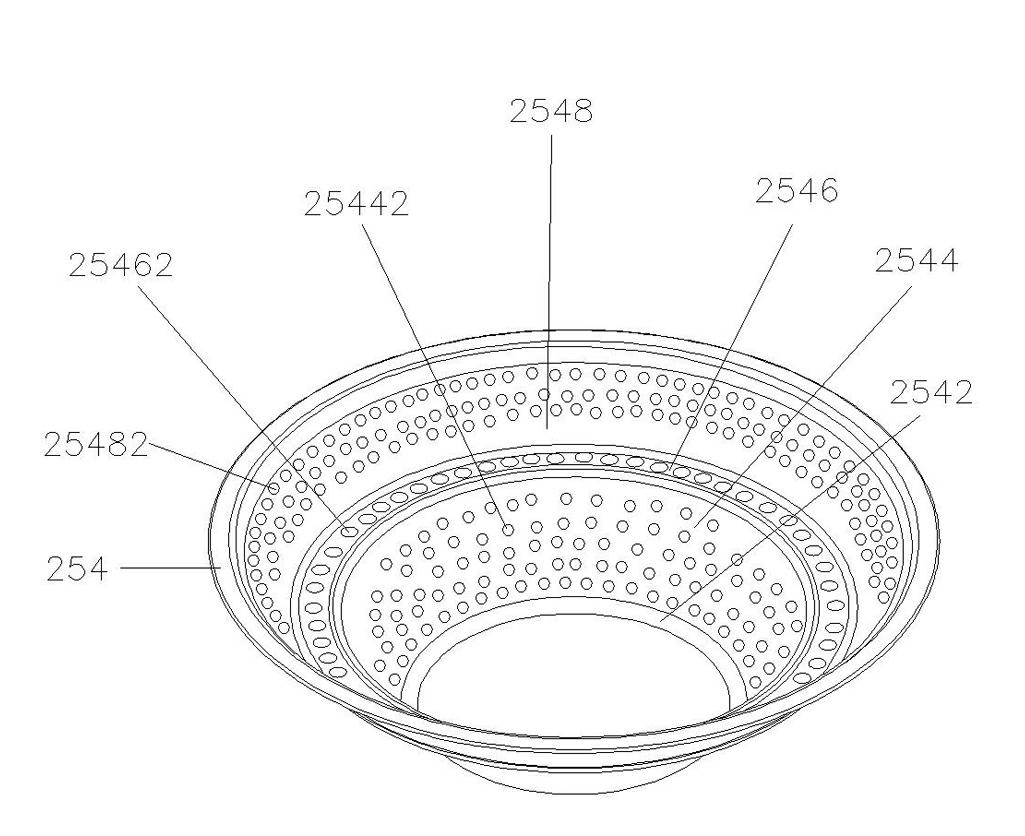

[0063] 1. The filter screen 254 of the present invention is additionally provided with a filter plate 2546. When the filter screen 254 of the present invention is applied to a traditional juice extractor, pomace is squeezed between the filter plate 2546 and the upper cover of the traditional juice extractor to further Squeeze out the juice, increase the squeezing force on the pomace, increase the juice yield and high juice extraction efficiency;

[0064] 2. The filter plate 2546 of the filter screen 254 of the present invention is provided with a number of second mesh holes 25462, which reduces the weight of the filter screen and stabilizes the filter screen, which can reduce vibration and noise;

[0065] 3. The filter plate 2546 of the filter screen 254 of the present invention is provided with a number of second mesh holes 25462, which increases the number of mesh holes on the filter...

no. 2 example

[0092] The second embodiment of the present invention has the following beneficial effects:

[0093] 1. The filter screen 354 of the present invention is provided with a filter plate 3546. When the filter screen 354 of the present invention is applied to a traditional juice extractor, pomace is squeezed between the filter plate 3546 and the upper cover of the traditional juice extractor to further Squeeze out the juice, increase the squeezing force on the pomace, increase the juice yield and high juice extraction efficiency;

[0094] 2. The filter plate 3546 of the filter screen 354 of the present invention is provided with a number of second mesh holes 35462 to reduce the weight of the filter screen and stabilize the filter screen, which can reduce vibration and noise;

[0095] 3. The filter plate 3546 of the filter screen 354 of the present invention is provided with a number of second mesh holes 35462, which increases the number of mesh holes on the filter screen, increases...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com