Squeeze type juice squeezing mechanism

A squeezing and juicing technology, which is used in household machinery, kitchen utensils, household utensils, etc. for filtering food, can solve problems such as increasing work difficulty, feeding difficulties, affecting work efficiency, etc., and achieves low design and production costs. Easy cleaning and assembly, saving time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

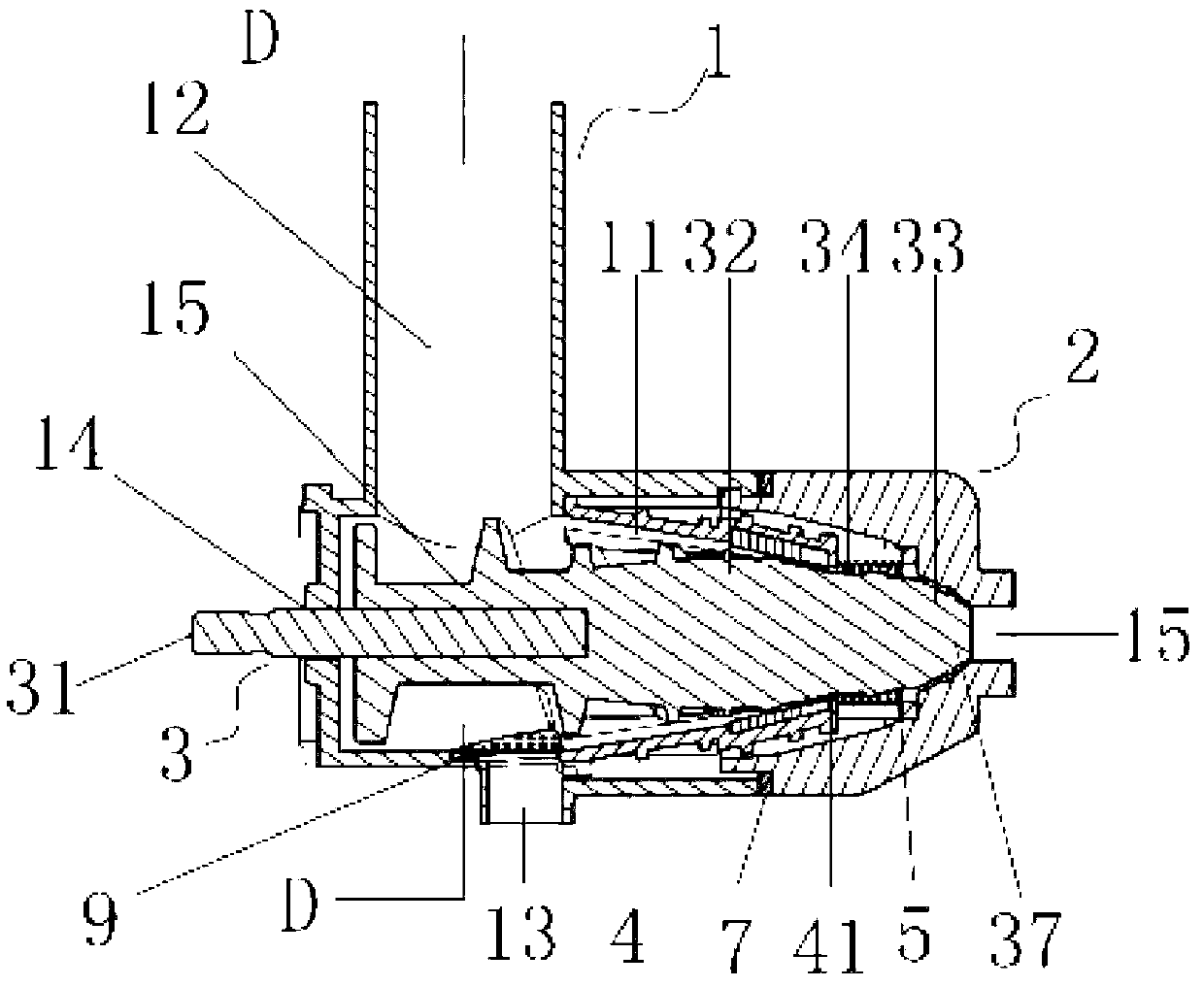

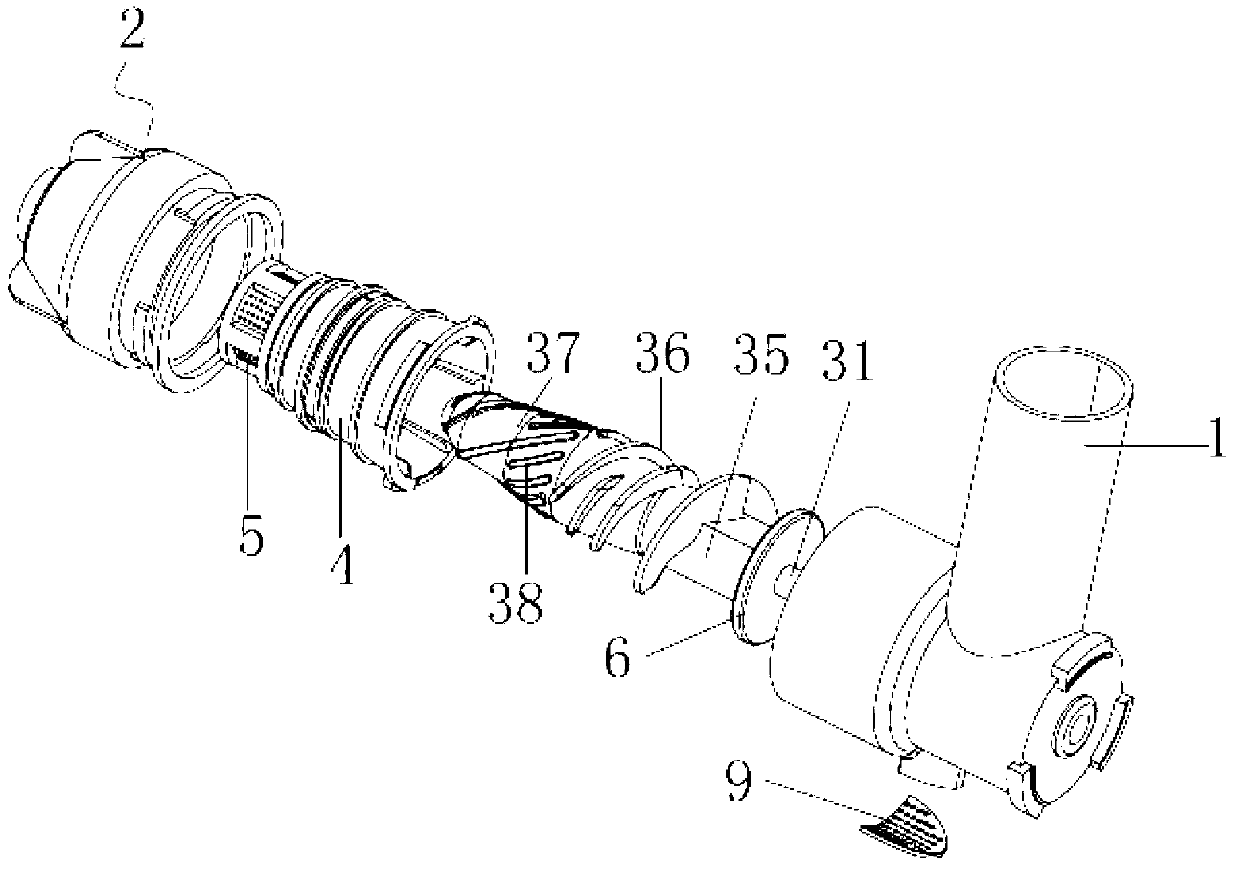

[0024] see Figure 1-Figure 3 , a squeeze-type juicing mechanism, including an outer shell 1, a screw 3 and a front cover 2 movably connected with the outer shell 1, the outer shell 1 and the front cover 2 are closed to form a cylindrical inner cavity, and the screw 3 Placed in the cylindrical inner cavity and reserved a gap for squeezing the juiced material between the outer shell 1 and the inner wall of the front cover 2, one end of the screw 3 runs through the end surface of the outer shell 1 and along the axial direction It is movable, and the screw rod 3 is respectively provided with a first limiting device and a second limiting device for restricting the screw rod 3 from exceeding the set active area in the axial direction.

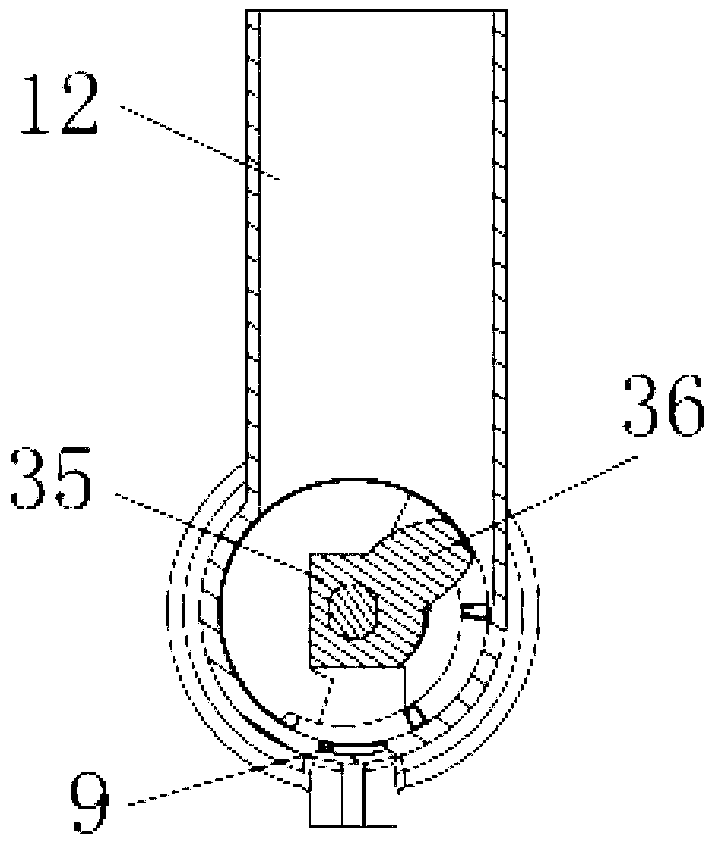

[0025] In this embodiment, the outer casing 1 includes a juice extracting chamber 11, a feed chamber 12 and a juice outlet chamber 13 connected to the juice extracting chamber 11, the juice extracting chamber 11 forms a cylindrical structure with on...

Embodiment 2

[0031] The difference between this embodiment and Embodiment 1 is that the front cover 2 of this embodiment forms an inner cavity 21 near the end surface, and the inner cavity 21 communicates with the cylindrical inner cavity on the inside, and the inner cavity 21 is connected to the cylindrical inner cavity. A silicone pad 8 is provided at the joint of the cylindrical inner cavity. This setting acts as a water leak-proof.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com