Coring-free complete core juicer

A juicer and juicing technology, which is used in household machinery, household appliances, and applications for filtering food, and can solve problems such as waste of nutrients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

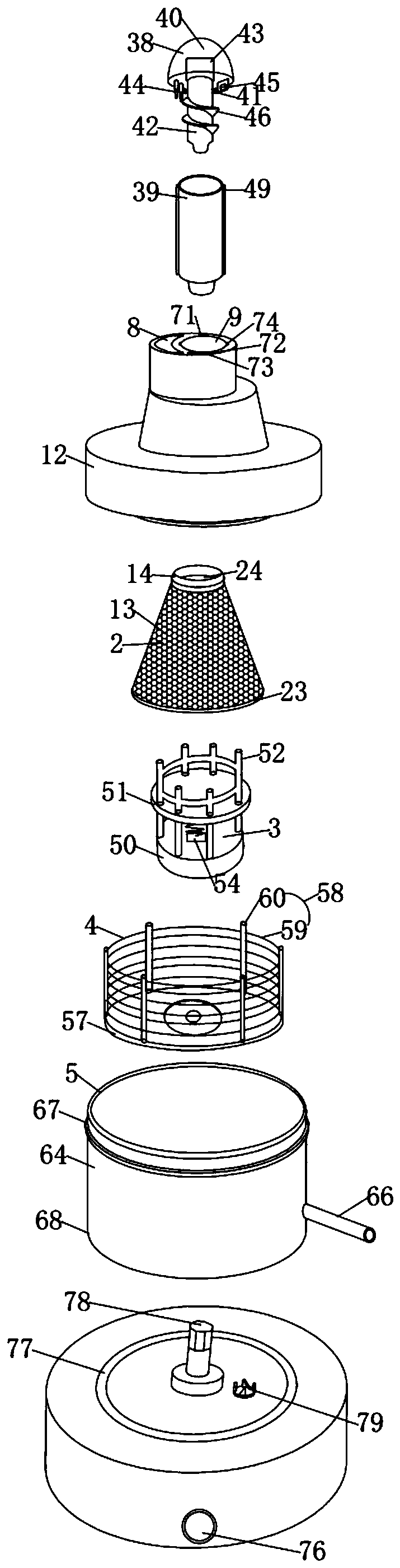

[0069] Example 1: Installing a nuclear-free whole-core juicer, the first step is to install the lower housing 5 on the base 6, so that the lower housing limit ring 68 is aligned with the base limit groove 77, and the first transmission part power source 78 Passing through the first transmission portion guide hole 70, the bottom of the second transmission portion transmission gear 69 is aligned with the second transmission portion power source 79; the second step is to install the filter 58 on the lower housing 5 so that the second transmission portion gear 63 and The second transmission portion transmission gear 69 is engaged, and the first transmission portion power source 78 passes through the first transmission portion through hole 62; the third step is to install the transmission limit spring seat 3 in the filter screen 58 so that the transmission base 50 is nested In the limit groove 61 of the transmission limit spring seat, the power source 78 of the first transmission sec...

Embodiment 2

[0070] Example 2: Juicing of small fruits and vegetables. After cleaning the small fruits and vegetables, put the fruits and vegetables into the sponge knife food channel 8, turn on the power switch 76, the fruits and vegetables move downward due to the force of gravity and the rotation of the ceramic blade 21, and the fruits and vegetables pass The squeezing and cutting of the outer wall 13 of the sponge knife and the inner wall 11 of the sponge knife cause the fruits and vegetables to be ground into juice and separated from the fruit core. The fruit and vegetable juice and the core are transferred into the filter basket 4 together, and the fruit and vegetable juice is shaken by the centrifugal force. The strainer basket 4 flows out through the juice outlet 66, and the fruit core remains in the strainer basket 4.

Embodiment 3

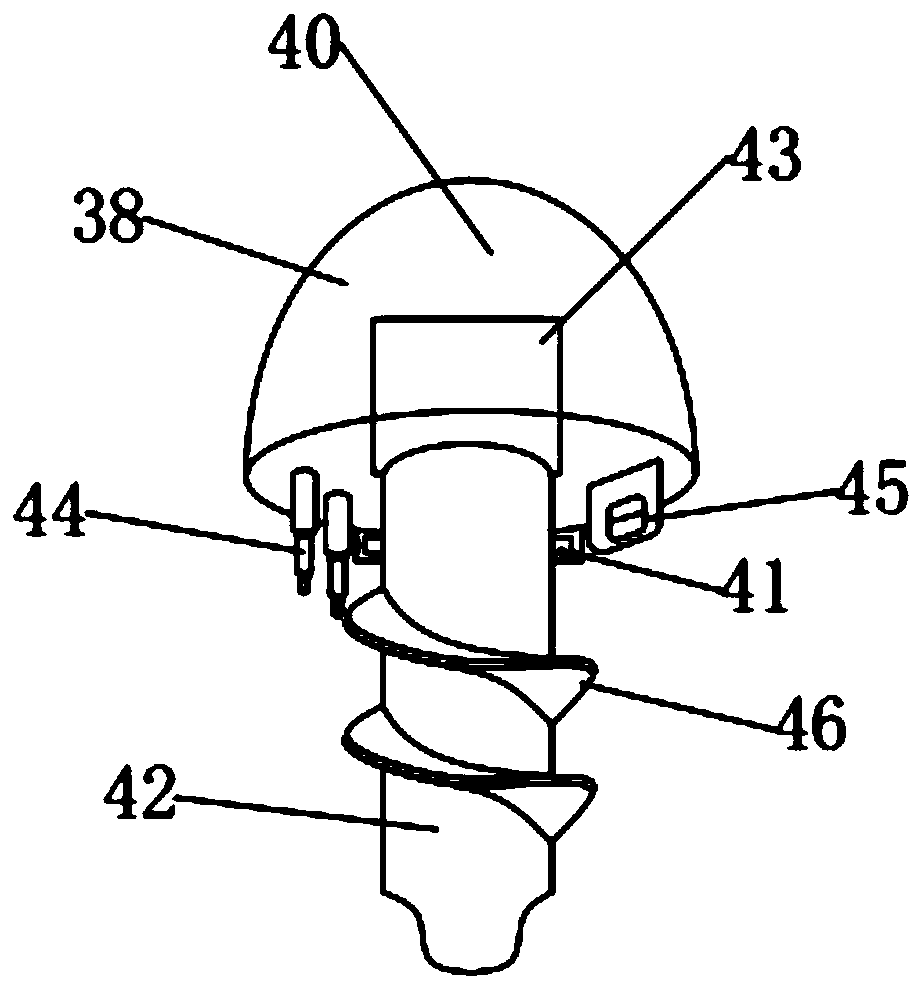

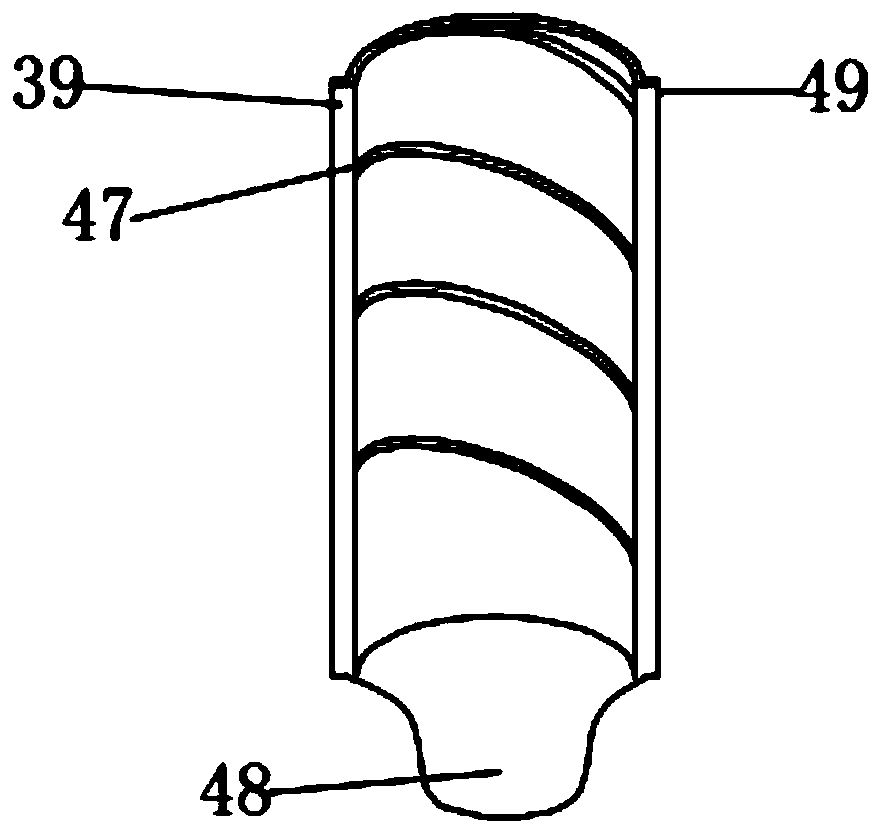

[0071] Example 3: Large-scale fruits or high-fiber fruits such as sugarcane enter the through hole 24 of the coreless juice squeezing head through the switch knife food channel 9 and install the juice squeezing pestle on the dual-channel top cover 1, turn on the power switch 76, The juice pestle motor 43 rotates, the juice pestle extension 39 slowly extends downward, and the fruits and vegetables slowly pass through the switch blade cutting plate 23 under the squeezing of the juice pestle and the spring carrier plate 51. During the rotation of the switch blade cutting plate 23 In the process, the pulp and core of large fruits are separated or the high-fiber fruit such as sugarcane is cut into juice. The pulp and core fall into the filter basket 4, and the core, juice and pulp enter the filter basket 4 through centrifugal force. At this time, the pressure sensor 54 located at the base 6 changes according to the pressure, and the fruit is tested to be completely cut. It transmits ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com