Easy cleaning extrusion type juicer

A squeezing and juicer technology, which is used in household machinery, household appliances, and applications for filtering food, can solve the problems of blocking material slag, materials are easy to block mesh holes, and mesh holes are blocked, so as to reduce friction. chance, effect of maintaining color and taste, reducing chance of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

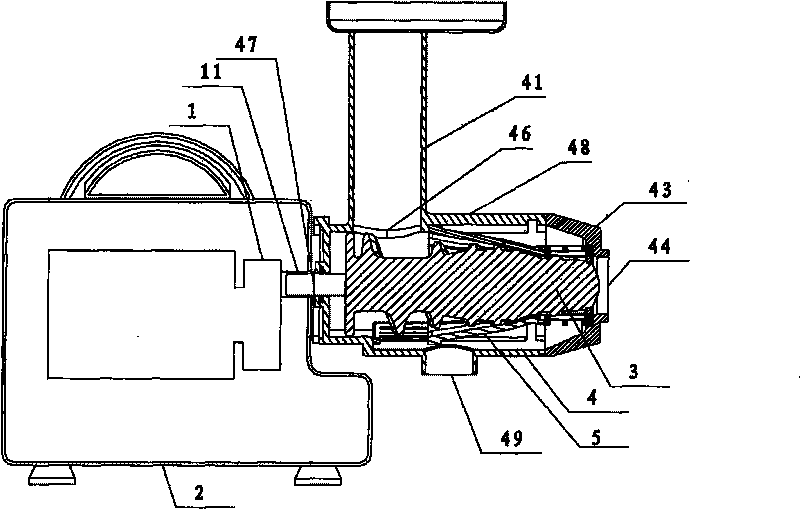

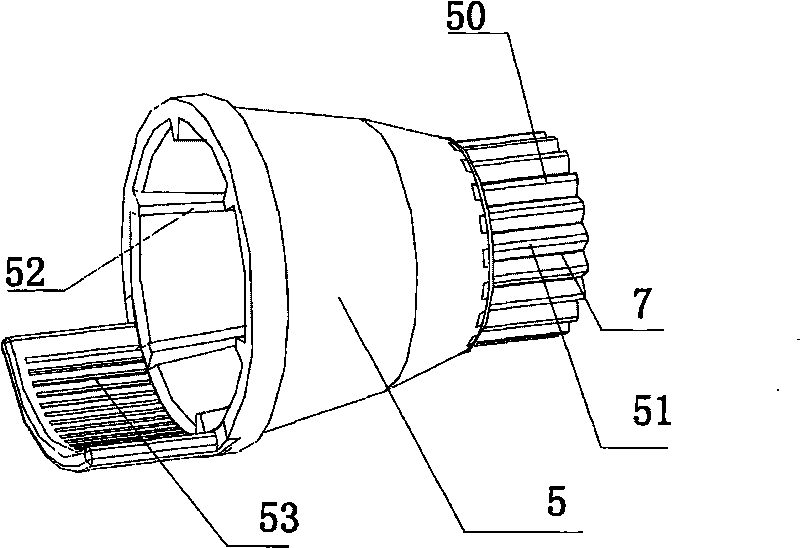

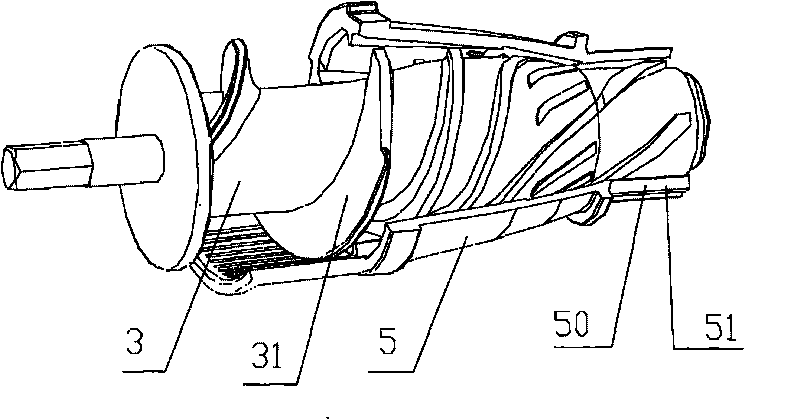

[0035] As embodiment one of the easy-to-clean squeezing juice extractor of the present invention, as Figure 1 to Figure 6 As shown, the propulsion screw 3, the extruding cylinder 5 and the filter part 50 are all arranged horizontally, the surface of the propulsion screw 3 is provided with several spirals 31, and the juice collection chamber 4 is located on one side of the machine base 2, The motor base 2 has a built-in motor 1, and the motor 1 is arranged horizontally. The easy-to-clean squeezing juice extractor also includes a feed channel 41 and an end cover 43, the cavity 48 of the juice collection chamber 4 is provided with a feed port 46, and the feed channel 41 is integrally arranged on the feed On the port 46, the cavity 48 of the juice collecting cavity 4 is also provided with a juice outlet 49. One end of the juice collecting cavity 4 is provided with a shaft hole 47 , and the motor shaft 11 passes through the shaft hole 47 and is connected with the propulsion screw...

Embodiment 2

[0048] As embodiment two of the easy-to-clean extruding juice extractor of the present invention, as Figure 7 , Figure 8 with Figure 9 As shown, the difference between this embodiment and Embodiment 1 is that, in this embodiment, the motor 1 is vertically arranged, and the propulsion screw 3 , extrusion barrel 5 and filter part 50 are all vertically arranged. The easy-to-clean squeeze juice extractor also includes a feed channel 41 and a chamber cover 45, the chamber cover 45 is fastened on the upper port of the juice collection chamber 4, and the chamber cover 45 is provided with a feed port 46, so The feed channel 41 is integrally arranged on the feed port 46 and communicates with the feed port 46. The lower end of the juice collection chamber 4 is installed on the machine base 2, and a shaft is arranged on the lower end surface of the juice collection chamber 4. hole 47, the motor shaft 11 passes through the shaft hole 47 and is connected with the propulsion screw 3 sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com