Bayberry wine preparation method

A technology of fruit wine yeast and dosage, applied in the preparation of alcoholic beverages, methods based on microorganisms, biochemical equipment and methods, etc., can solve the problems of short preservation time, inability to squeeze, and inedible green fruits, etc., and achieve juice extraction rate High, the effect of improving the juice extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

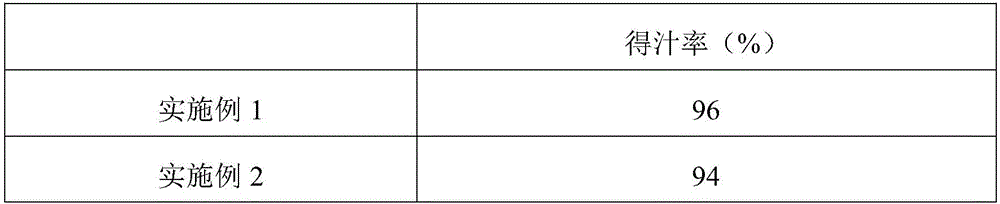

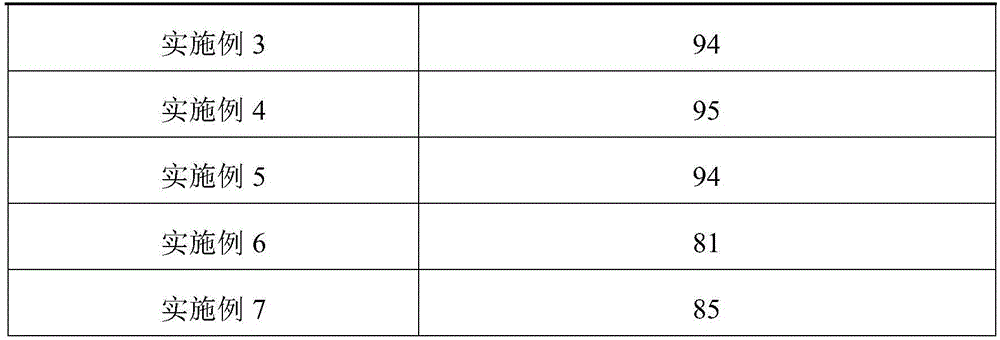

Examples

Embodiment 1

[0023] Embodiment 1: the preparation of bayberry wine

[0024] Step S1, raw material processing: select fresh and ripe red bayberry, wash and drain;

[0025] Step S2, crushing and squeezing the juice: mix the drained red bayberry with citric acid and sodium citrate, put it into a crusher and a squeezer to crush and squeeze the juice in turn, and remove the red bayberry core; the amount of citric acid added is 0.08% of the weight of the red bayberry , the added amount of sodium citrate is 4 times of the added amount of citric acid;

[0026] Step S3, first fermentation: transport bayberry juice to a fermenter, add fruit wine yeast and sugar for fermentation, the temperature in the fermenter is 24°C, and ferment for 7 days; add 0.5 catties of fruit wine yeast and 9 catties of sugar for every 100 catties of bayberry juice ;

[0027] Step S4, secondary fermentation: add white sugar, continue fermentation for 20 days, add 6 catties of white sugar for every 100 catties of red bayber...

Embodiment 2

[0031] Embodiment 2: the preparation of red bayberry wine

[0032] Step S1, raw material processing: select fresh and ripe red bayberry, wash and drain;

[0033] Step S2, crushing and juicing: mix the drained red bayberry with citric acid and sodium citrate, put it into a crusher and a squeezer to crush and squeeze the juice in turn, and remove the red bayberry core; the amount of citric acid added is 0.07% of the weight of the red bayberry , the added amount of sodium citrate is 3 times of the added amount of citric acid;

[0034] Step S3, first fermentation: transport bayberry juice to a fermenter, add fruit wine yeast and sugar for fermentation, the temperature in the fermenter is 23°C, and ferment for 8 days; add 0.4 catties of fruit wine yeast and 8 catties of sugar for every 100 catties of bayberry juice ;

[0035] Step S4, secondary fermentation: add white sugar, continue fermentation for 19 days, add 5 catties of white sugar for every 100 catties of red bayberry juice...

Embodiment 3

[0039] Embodiment 3: the preparation of bayberry wine

[0040] Step S1, raw material processing: select fresh and ripe red bayberry, wash and drain;

[0041] Step S2, crushing and squeezing the juice: mix the drained red bayberry with citric acid and sodium citrate, put it into a crusher and a squeezer to crush and squeeze the juice in turn, and remove the red bayberry core; the amount of citric acid added is 0.09% of the weight of the red bayberry , the amount of sodium citrate added is 5 times that of citric acid;

[0042] Step S3, first fermentation: transport bayberry juice to a fermenter, add fruit wine yeast and sugar for fermentation, the temperature in the fermenter is 25°C, and ferment for 6 days; add 0.6 catties of fruit wine yeast and 10 catties of sugar for every 100 catties of bayberry juice ;

[0043] Step S4, secondary fermentation: add white sugar, continue fermentation for 21 days, add 7 catties of white sugar for every 100 catties of red bayberry juice;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com