Method for preparing perovskite quantum dots by low-temperature solution process

A low-temperature solution method, perovskite technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of complicated operation, increased experimental operation, and great impact on the precursor environment, and achieves simple operation, high development value, and high development value. The effect of high photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

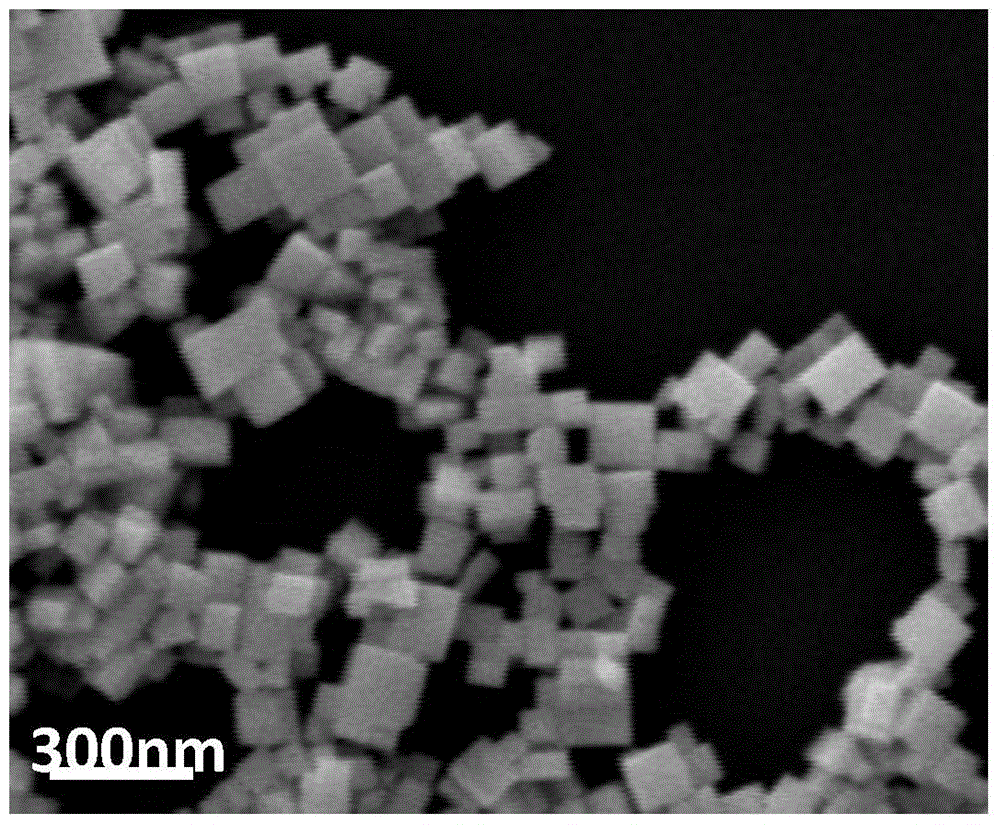

[0027] Synthesis of CsPbBr by low temperature solution method described in this embodiment 3 The synthetic method of perovskite quantum dots specifically comprises the following steps:

[0028] 1) Add 80mL of toluene to the round bottom flask and place it in a heating mantle at 80°C. After keeping the temperature stable at 80°C, turn on the magnetic stirring at a stirring speed of 800r / min. The heating and stirring are carried out in the air without inertness Gas protection.

[0029] 2) the metal halide salt PbBr 2 and CsBr were completely dissolved in DMSO at a molar ratio of 1:1 to form a precursor solution.

[0030] 3) Then add 5-10 drops of oleic acid / oleylamine (volume ratio 10:1) mixture into the DMSO solution as a surfactant, and mix the solution evenly.

[0031] 4) Rapidly inject the prepared precursor mixture into toluene that is being heated and stirred at a volume ratio of 1:80, react for 5-10 seconds, and rapidly cool to room temperature with water.

[0032] 5)...

Embodiment 2

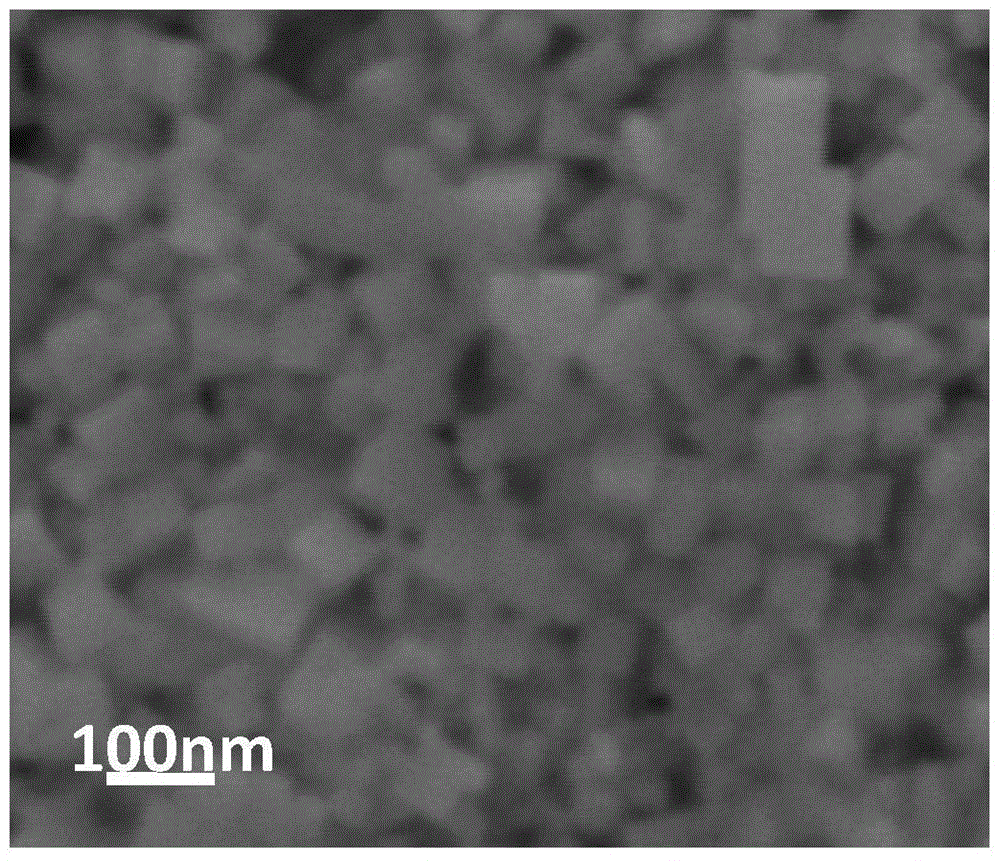

[0034] Similar to Example 1, the difference is that the temperature in step 1) of Example 1 is changed to 0° C., the heating device is changed to an ice bath, and other conditions remain the same.

Embodiment 3

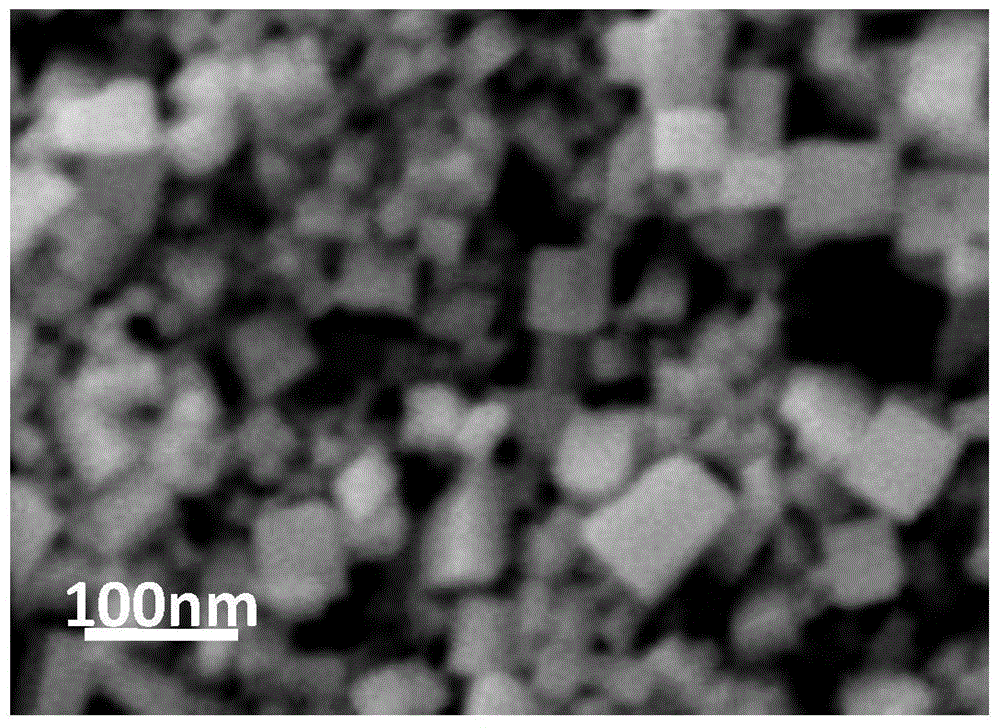

[0036] Similar to Example 1, the difference is that the temperature in step 1) of Example 1 is changed to 140° C., and other conditions remain the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com