Preparation method of metal halide inorganic perovskite quantum dots

A technology of metal halide and metal halide, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems of large impact on device performance, uneven size of nanosheets, and very large impact, and achieve short reaction time and product formation The effect of high rate and high repetition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step 1. Add 80mL of toluene to a 100mL round-bottomed flask respectively. At room temperature, turn on magnetic stirring at a stirring speed of 800r / min. Heat and stir in air without inert gas protection;

[0030] Step 2, metal halide salt PbBr 2 Dissolve CsBr and CsBr in 2mL DMSO at a molar ratio of 1:1, ultrasonically dissolve the metal halide salt completely, and the concentration of the metal halide salt is 1mol / L;

[0031] Step 3. Add 0.1-1 mL of oleic acid as a surfactant to the DMSO solution of the metal halide salt, and mix the solution evenly;

[0032] Step 4. Quickly inject the mixed solution prepared in step 3 into the heated and stirred toluene, centrifuge the obtained reaction product at 8000r / min for 3min, remove the supernatant, and redisperse the precipitate in toluene to obtain CsPbBr 3 Nanocrystalline quantum dots.

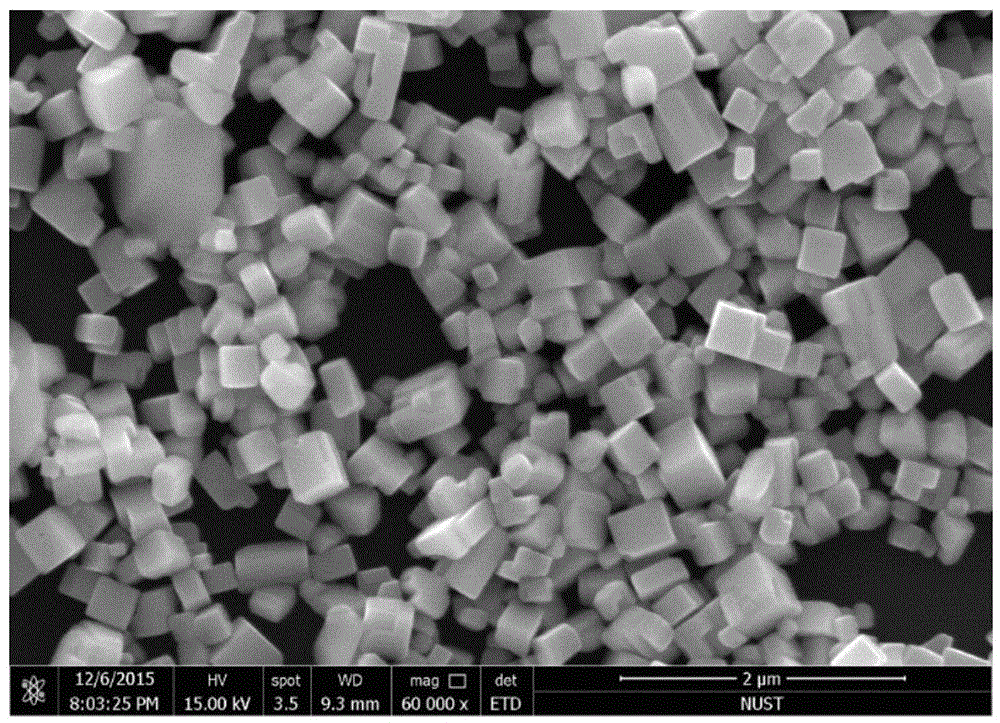

[0033] The CsPbBr that this embodiment makes 3 The morphology of nanocrystalline quantum dots is as figure 1 As shown, its photolumin...

Embodiment 2

[0035] This embodiment is the same as embodiment 1, the only difference is that the reaction solvent in step 1 is isopropanol, and others are the same as embodiment 1.

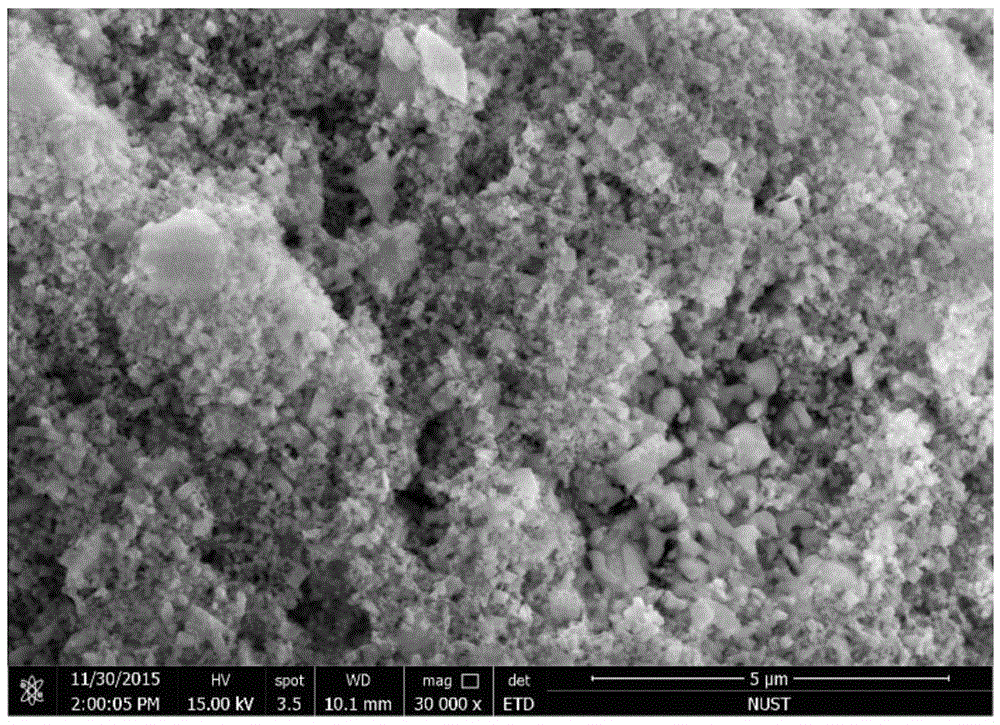

[0036] The CsPbBr that this embodiment makes 3 The morphology of nanocrystalline quantum dots is as figure 2 As shown, its photoluminescence diagram is shown in Figure 10 Curve 2, the emission wavelength is 521.9nm.

Embodiment 3

[0038] This embodiment is the same as Example 1, except that the reaction solvent in step 1 is acetone, and the others are the same as Example 1.

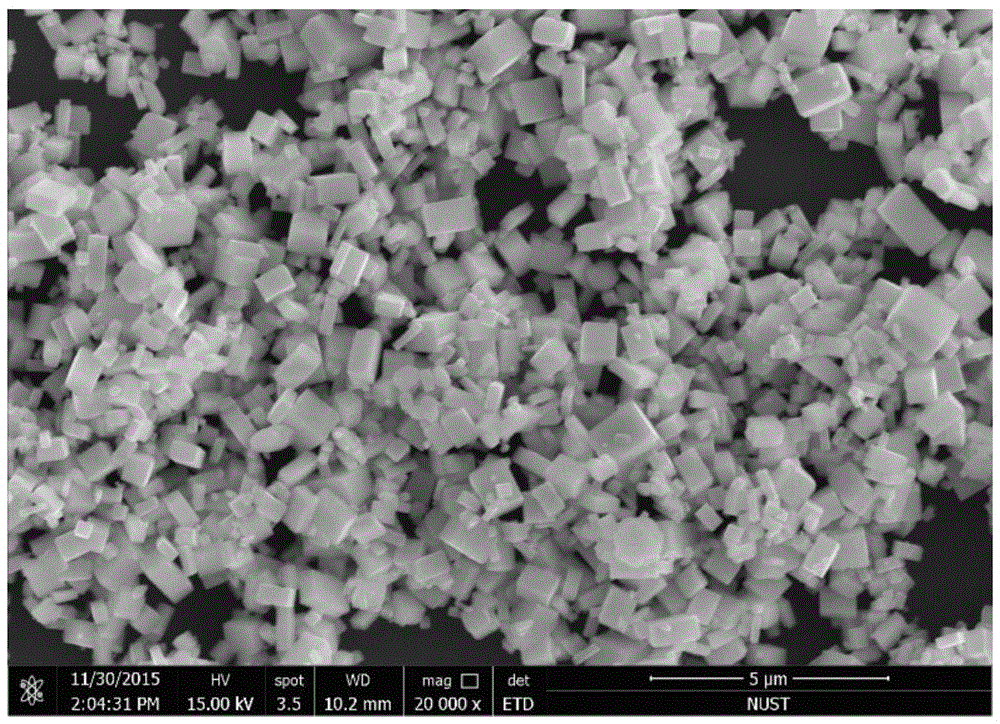

[0039] The CsPbBr that this embodiment makes 3 The morphology of nanocrystalline quantum dots is as image 3 As shown, its photoluminescence diagram is shown in Figure 10 Curve 3, the emission wavelength is 522.0nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com