Cannabis sailve extract rich in cannabidiol and preparation method of cannabis sailve extract

A cannabidiol and hemp technology, which is applied in the directions of medical preparations, pharmaceutical formulations, and plant raw materials containing active ingredients to achieve the effects of good color, high CBD content and improved extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] 1) Preparation of sample solution

[0035] Accurately weigh 0.1 gram of the extract product, add 5 milliliters of chloroform to dissolve it into a solution, then pass through an organic membrane of 0.22 μm in an ultrasonic bath for 5 minutes, and store the obtained filtrate in a refrigerator for later use.

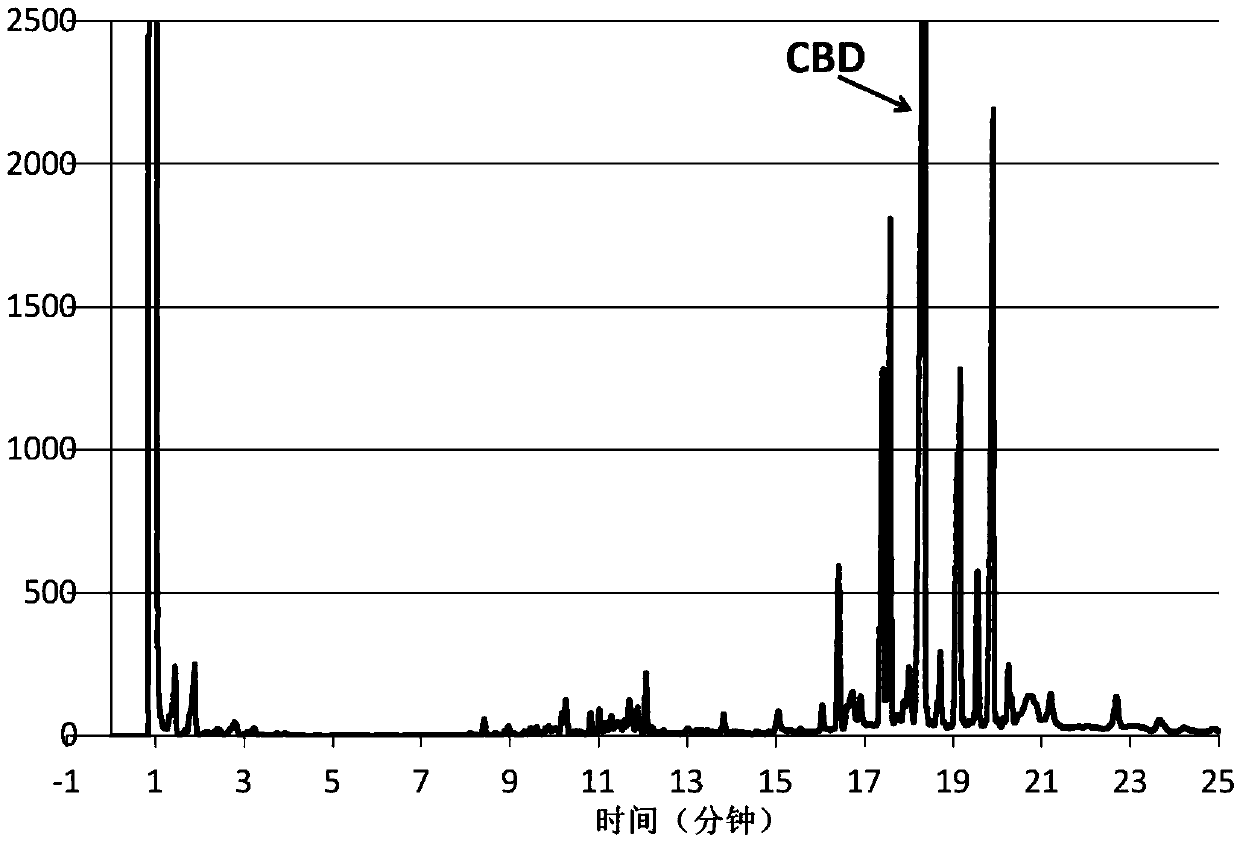

[0036] 2) Determination of CBD content

[0037]Use AgilentHP-5 column, Agilent7890A type gas chromatograph to measure. The chromatographic conditions are as follows: the carrier gas is helium, and the flow rate is 1.00 ml / min; Hold for 10 minutes; inlet temperature 150°C, detector temperature 300°C, split ratio 5:1; hydrogen flow rate 40 ml / min, air flow rate 400 ml / min; automatic injection, injection volume 4.0 μL. Prepare standard solutions of different concentrations to perform the above operations, and draw a peak area-CBD concentration standard curve. The determination was carried out according to the above method, the injection volume of the sample solution...

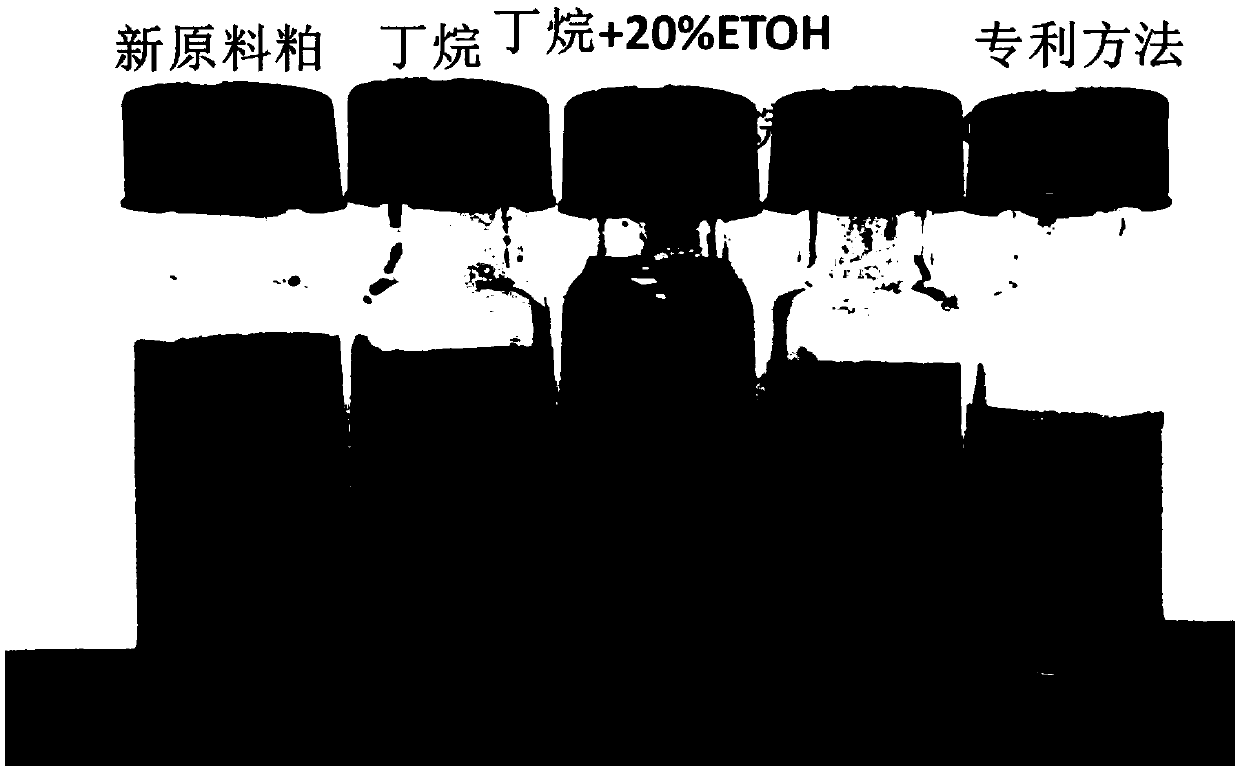

Embodiment 1

[0039] Spread the dried hemp mosaic leaves in an oven for dry heat treatment, the temperature is set at 80° C., and the time is 2 hours, and then it is ground with a pulverizer. Get 1.5 kilograms of hemp flower leaves of dry heat treatment, sub-pack with some filter bags, place in the extraction tank of subcritical extraction device, mix the technical grade n-butane in the solvent tank by solid-liquid ratio 1:8 (W / V) Inject into the material tank, extract for 40 minutes at a subcritical state with a temperature of 35°C and an extraction pressure of 0.4 MPa, and repeat the extraction 3 times to obtain a crude extract. The crude extract was dissolved by adding ethanol at a solid-to-liquid ratio of 1:5 (W / V); then placed in a refrigerator at -10°C for winterization for 60 minutes. Then it was transferred to a centrifuge whose temperature was set to -6°C in advance and whose rotation speed was 4500 rpm, and centrifuged for 30 minutes. Activated carbon was added to the supernatant...

Embodiment 2

[0041] Spread the dried hemp mosaic leaves in a general oven for dry heat treatment, the temperature is set at 80° C., and the time is 2 hours. Then grind it with a pulverizer. Take 1.5 kg of dried hemp mosaic leaves, pack them with filter bags, and place them in the extraction tank of the subcritical extraction device. First, measure 95% ethanol and put it into the extraction tank, and then send it into the corresponding volume of n-butane through the flow valve of the equipment. , so that the concentration of ethanol in the solvent tank reaches 20% of n-butane, inject the mixed n-butane solvent into the material tank, and extract for 40 minutes at a subcritical state with a temperature of 40°C and an extraction pressure of 0.4MPa, and an extraction temperature of 55°C , extracted for 40 min, and then desolvated under reduced pressure, the extract was taken out, and the extraction was repeated 3 times. Add a certain amount of ethanol to the ethanol solution containing the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com