Method for preparing perovskite quantum dot at room temperature

A perovskite and quantum dot technology, applied in chemical instruments and methods, lead compounds, inorganic chemistry, etc., can solve problems such as anion exchange, change in emission wavelength, and limit applications in the display field, and achieve mild reaction conditions and short reaction time. , the effect of high photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

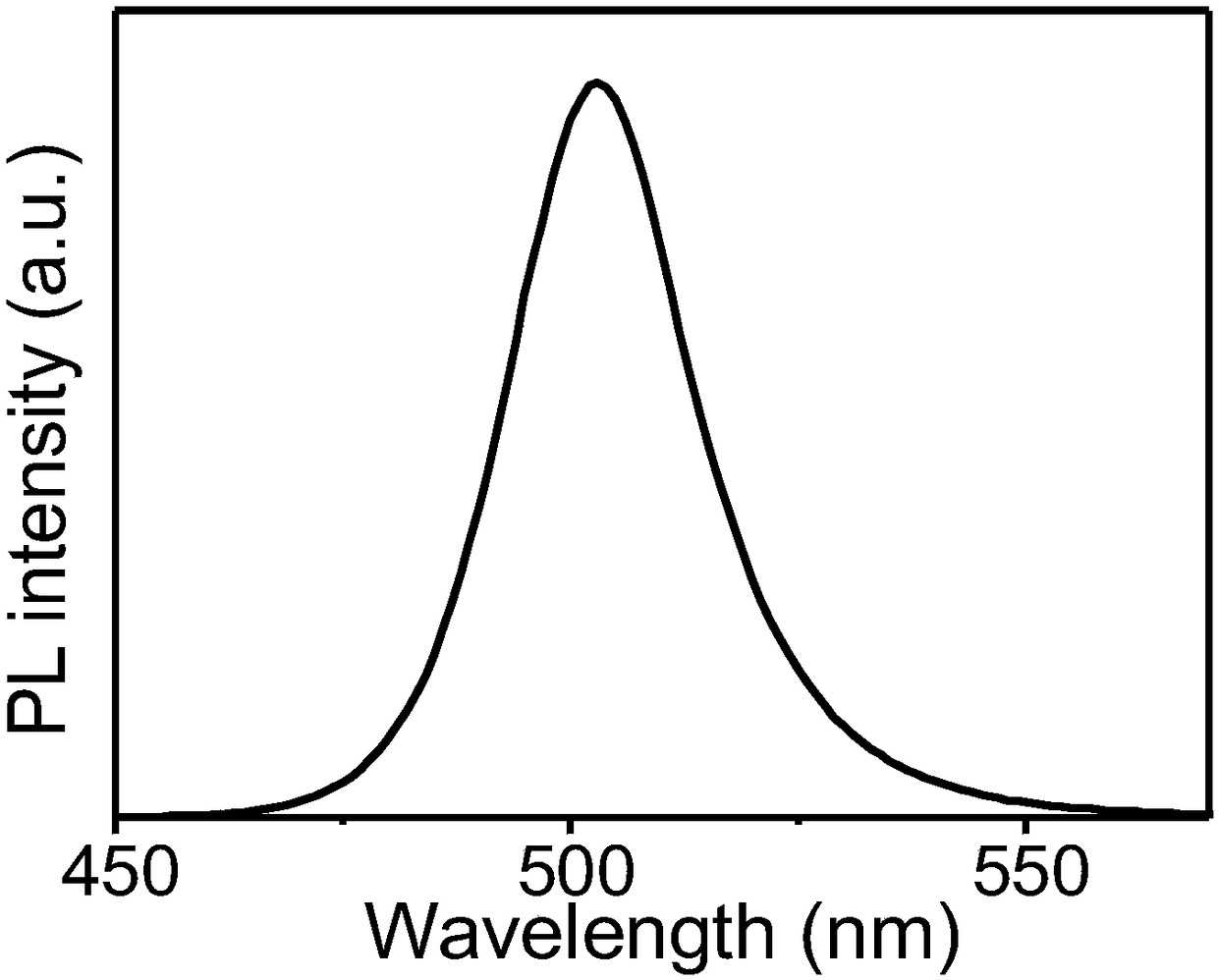

Embodiment 1

[0023] Synthesis method of organic perovskite quantum dots at room temperature (20-30°C): the metal halide salt PbBr 2 It is weighed 1:1 with MABr by molar ratio, and then put into a 15mL strain bottle. Then add 4-7ml DMF and 0.1mmol DMSO. Turn on the magnetic stirring at a stirring speed of 800-1200r / min, and fully stir for 30-50min to completely dissolve the solute and form a precursor solution. Then quickly add the surfactant BA solution to the precursor solution, and the molar ratio of the surfactant to MABr is 1:1, and react for 18-24 hours to make the solution evenly mixed. It does not require high temperature heating or inert gas protection, just At room temperature.

[0024] Quickly inject the prepared mixed solution into the chlorobenzene solution with a volume ratio of 1:30 (quick stirring). The resulting target solution.

[0025] Centrifuge the above-mentioned reaction product and centrifuge at 800-1200rpm for 2-5min to remove the precipitate. Take out the supernatant...

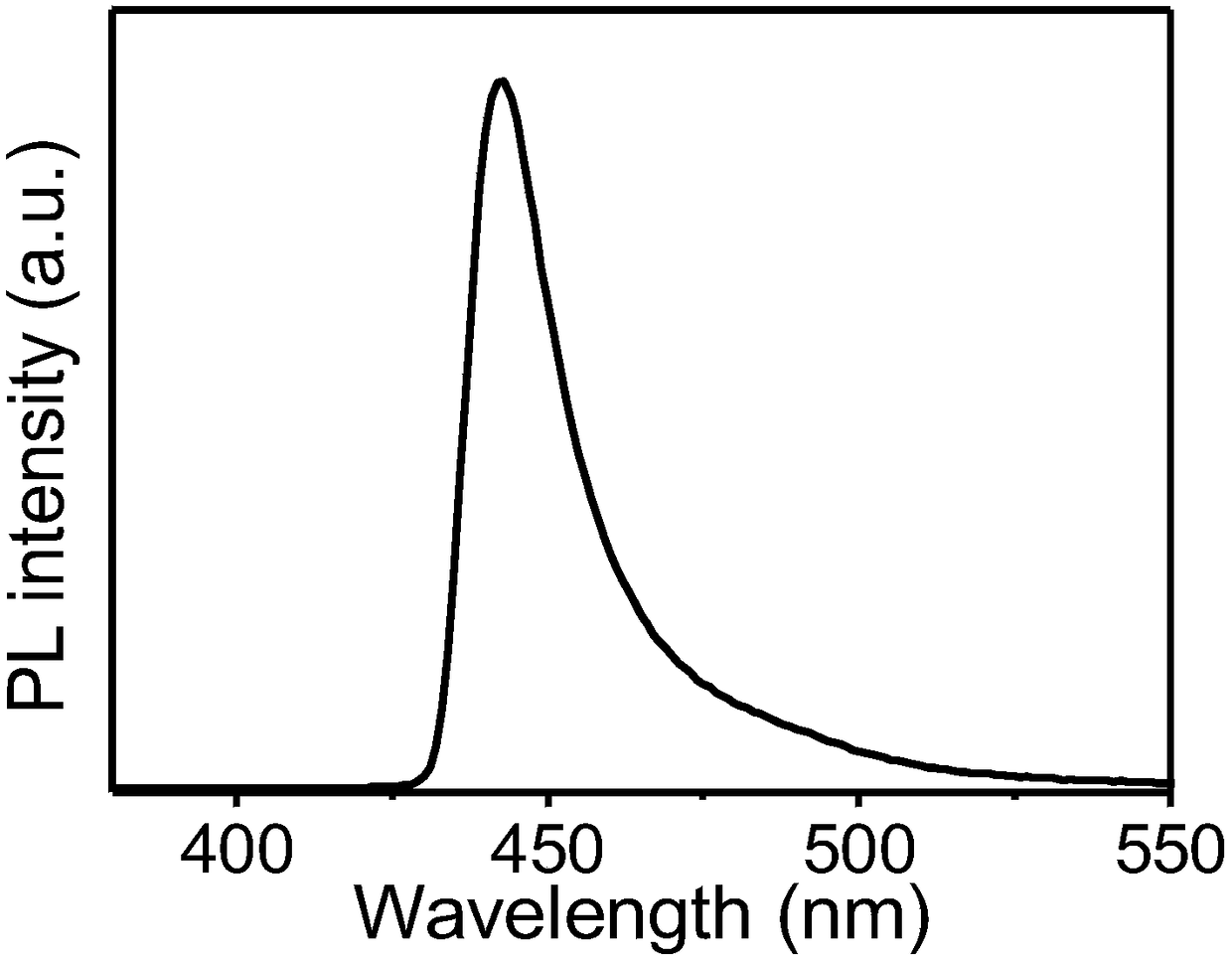

Embodiment 2

[0028] Synthesis method of organic perovskite quantum dots at room temperature (20-30°C): the metal halide salt PbBr 2 It is weighed 1:1 with MABr by molar ratio, and then put into a 15mL strain bottle. Then add 4-7ml DMF and 0.1mmol DMSO. Turn on the magnetic stirring at a stirring speed of 800-1200r / min, and fully stir for 30-50min to completely dissolve the solute and form a precursor solution. Then quickly add the surfactant BA solution to the precursor solution, and the molar ratio of the surfactant to MABr is 3:1, and react for 18-24 hours to make the solution evenly mixed. There is no need for high temperature heating, no inert gas protection, just At room temperature.

[0029] Quickly inject the prepared mixed solution into the chlorobenzene solution with a volume ratio of 1:30 (quick stirring). The resulting target solution.

[0030] Centrifuge the above-mentioned reaction product and centrifuge at 800-1200rpm for 2-5min to remove the precipitate. Take out the supernata...

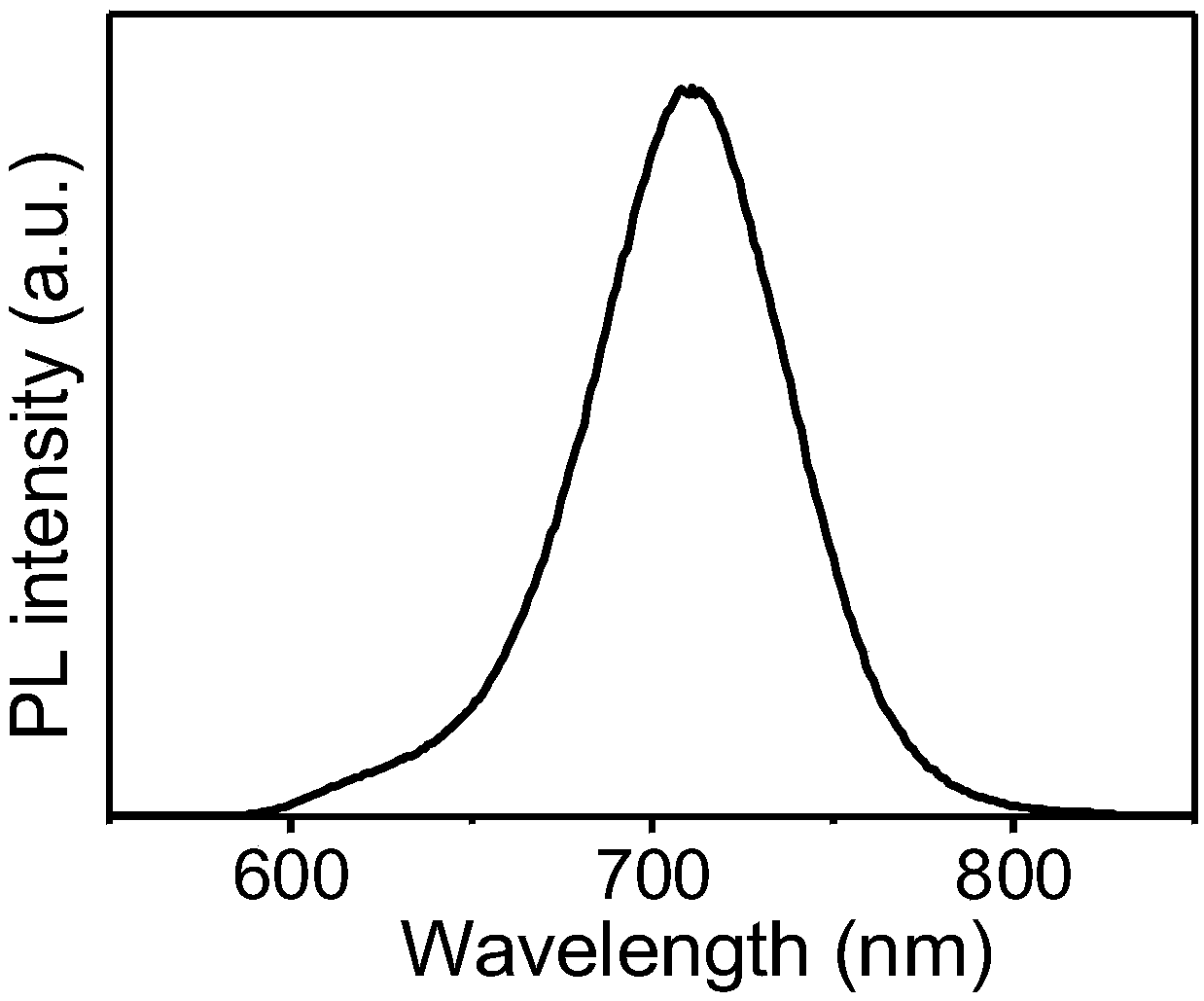

Embodiment 3

[0032] Synthesis method of organic perovskite quantum dots at room temperature (20-30℃): the metal halide salt PbI 2 It is weighed 1:1 with MAI massager ratio and put into a 15mL strain bottle. Then add 4-7ml DMF and 0.1mmol DMSO. Turn on the magnetic stirring at a stirring speed of 800-1200r / min, and fully stir for 30-50min to completely dissolve the solute and form a precursor solution. Then quickly add the surfactant BA solution to the precursor solution, and the molar ratio of surfactant to MAI is 1:1, react for 18-24 hours to make the solution evenly mixed without high temperature heating or inert gas protection, just At room temperature.

[0033] Quickly inject the prepared mixed solution into the chlorobenzene solution with a volume ratio of 1:30 (quick stirring). The resulting target solution.

[0034] Centrifuge the above-mentioned reaction product and centrifuge at 800-1200rpm for 2-5min to remove the precipitate. Take out the supernatant and centrifuge at 11000-15000r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com