Preparation method for poly(melamine-formaldehyde) polymeric microsphere three-dimensional template material

A technology of polymelamine and formaldehyde polymers, applied in the field of polymer microsphere science and application, can solve the problems of large surface reaction ability of coagulation, irregular spatial matrix arrangement, uneven particle size of microspheres, etc., and achieve great application potential , low cost, regular and orderly structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

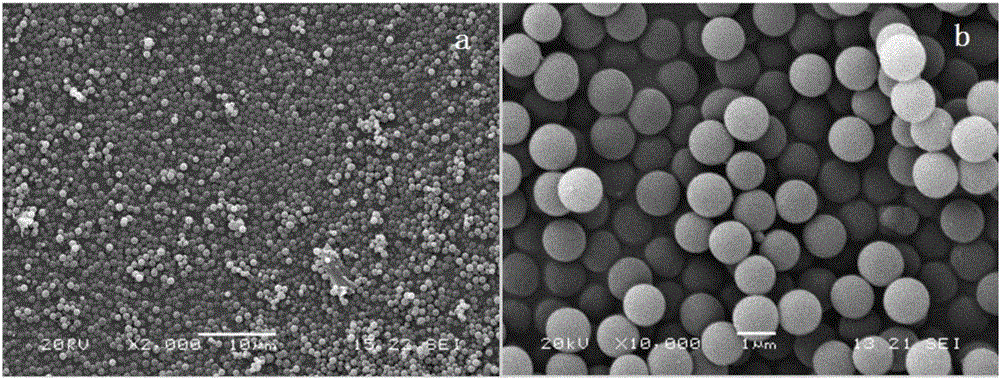

[0017] A method for preparing a polymelamine-formaldehyde polymer microsphere three-dimensional template material comprises the following steps: first, melamine and formaldehyde are added to 100ml of deionized water at a molar ratio of 1:10, and fully stirred at room temperature to make them evenly mixed. Then the temperature of the solution was slowly raised from room temperature to 85°C, and the temperature was kept for 60 minutes for prepolymerization, and then 1 part of formic acid was added dropwise to the solution (the mass ratio of 1 part of formic acid to melamine monomer was 1:12.5) to adjust the pH. The precipitation reaction was continued for 80 min. After the reaction, the product is centrifuged and washed with water to obtain polymelamine-formaldehyde microspheres in the form of white solid powder. Disperse the above polymelamine-formaldehyde microspheres in water to obtain a monodisperse polymelamine-formaldehyde microsphere emulsion with a solid-to-liquid ratio ...

Embodiment 2

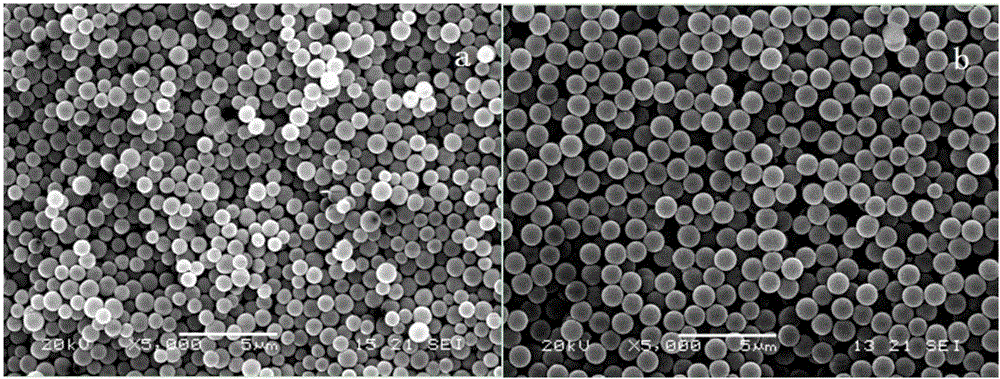

[0019] A method for preparing a polymelamine-formaldehyde polymer microsphere three-dimensional template material, comprising the following steps: first, adding melamine and formaldehyde into 100ml of deionized water at a molar ratio of 1:50, and fully stirring at room temperature to make them evenly mixed. Then the temperature of the solution is slowly raised from room temperature to 30°C, and the prepolymerization reaction is carried out at the temperature for 30 minutes, and 1 part of formic acid is added dropwise to the solution (the mass ratio of 1 part of formic acid to melamine monomer is 1:5) to adjust the pH, and continue The precipitation reaction was carried out for 50 min. After the reaction, the product is centrifuged and washed with water to obtain polymelamine-formaldehyde microspheres in the form of white solid powder. Disperse the above-mentioned polymelamine-formaldehyde microspheres in water to obtain a monodisperse polymelamine-formaldehyde microsphere emul...

Embodiment 3

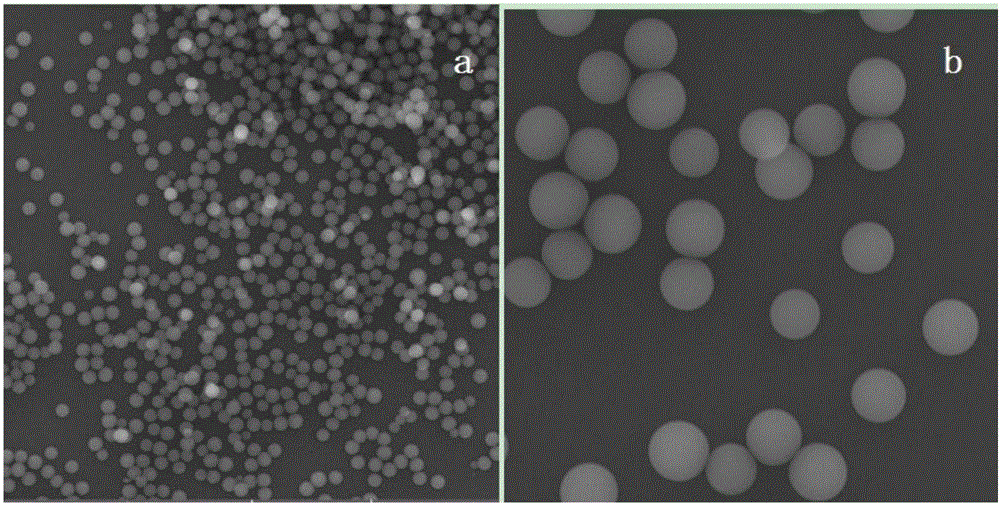

[0021] A method for preparing a polymelamine-formaldehyde polymer microsphere three-dimensional template material, comprising the following steps: first, adding melamine and formaldehyde into 100ml of deionized water at a molar ratio of 1:16, and fully stirring at room temperature to make them evenly mixed. Then the temperature of the solution was slowly raised from room temperature to 80°C, and the prepolymerization reaction was carried out at the temperature for 20 minutes, and 1 part of formic acid was added dropwise to the solution (the mass ratio of 1 part of formic acid to melamine monomer was 1:15.) to adjust the pH, The precipitation reaction was continued for 40 min. After the reaction, the product is centrifuged and washed with water to obtain polymelamine-formaldehyde microspheres in the form of white solid powder. Disperse the above polymelamine-formaldehyde microspheres in water to obtain a monodisperse polymelamine-formaldehyde microsphere emulsion with a solid-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com