Rapid preparation method of totally-biodegradable composite membrane with nanometer silver on surface

A surface-loaded, nano-silver technology, applied in coatings and other directions, can solve the problems of low degree of binding of cellulose nano-crystal reduction points, nano-silver can not really play an antibacterial effect, and the antibacterial effect of Staphylococcus aureus is weakened. The preparation process is simple and controllable, the synergistic enhancement effect is improved, and the particle size is controllable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

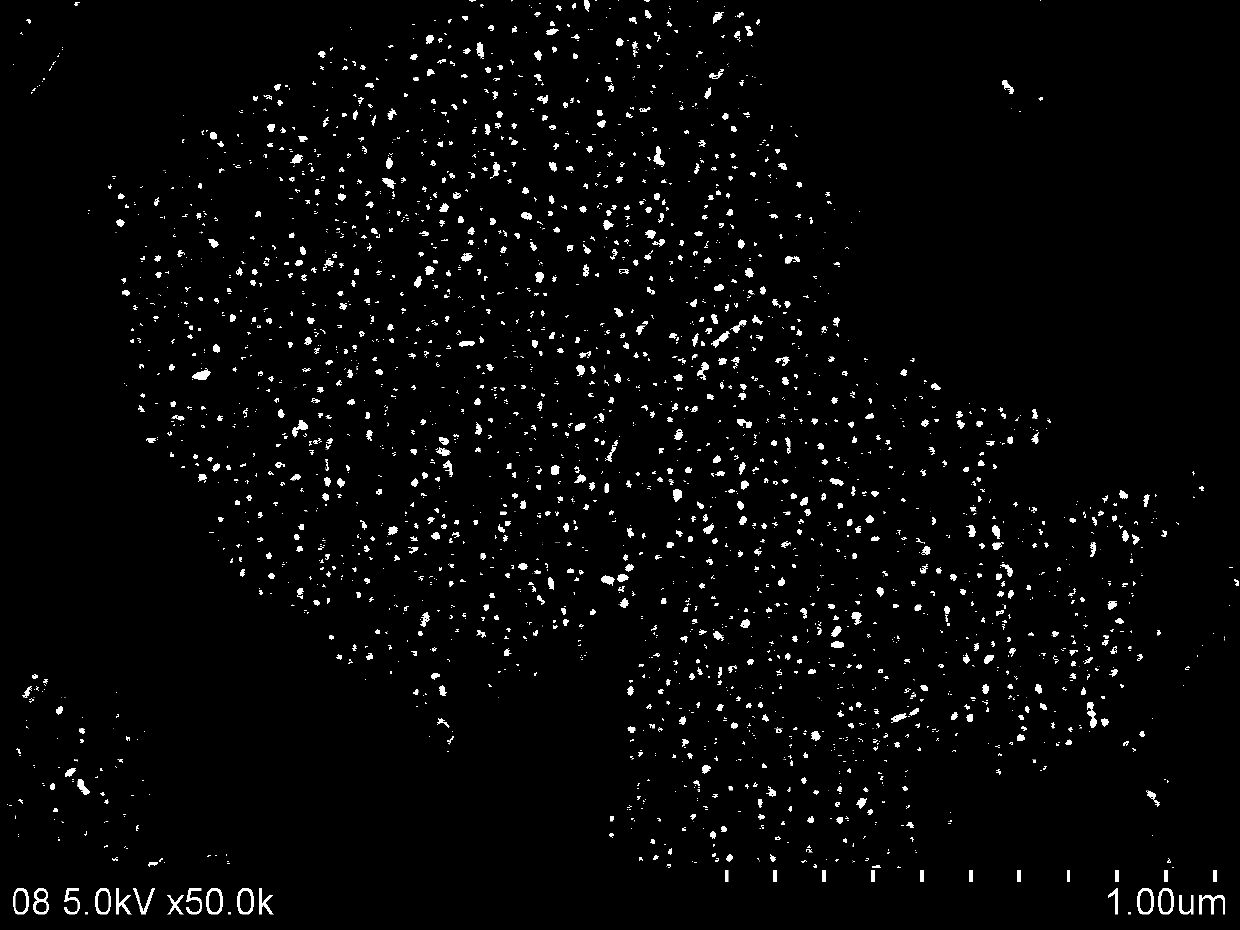

[0031]Bamboo fibers were added to formic acid / hydrochloric acid solution, the solid-to-liquid ratio of bamboo fibers to the mixed acid aqueous solution was 1:60 g / mL, and the volume ratio of formic acid (9 mol / L) to hydrochloric acid (5 mol / L) in the mixed acid aqueous solution was 6:1, the mixed solution was reacted at 50 ℃ for 12 h, and after the reaction was completed, the reaction product was washed with deionized water until it was neutralized to obtain the aldylated cellulose nanocrystals; under ultrasonic stirring, the aldylated cellulose nanocrystals Crystals are added to a chloroform solution in which polypropylene carbonate is dissolved, wherein the mass ratio of cellulose nanocrystals to polypropylene carbonate is 20:80; the cellulose nanocrystals / polypropylene carbonate of aldehydes The mass fraction of the ester in its chloroform solution is 30%, to obtain a mixed solution; the above mixed solution is directly coated on a glass plate, and after the product is dried...

Embodiment 2

[0033] Add the hemp fiber to the glyoxylic acid / sulfuric acid solution, where the solid-to-liquid ratio of the hemp fiber to the mixed acid aqueous solution is 1:40 g / mL, and the glyoxylic acid (3 mol / L) and sulfuric acid (10 mol / L) in the mixed acid aqueous solution The volume ratio of the mixture was 8:1, and the mixture was reacted at 70 °C for 14 h. After the reaction, the reaction product was washed with deionized water until it was neutral, and aldehyde-formed cellulose nanocrystals were obtained; under ultrasonic stirring, the aldehyde-formylated The cellulose nanocrystal is added in the dichloromethane solution that is dissolved with polybutene succinate, wherein the mass ratio of the cellulose nanocrystal of formylation and polybutene succinate is 15:85; The mass fraction of prime nanocrystal / polybutylene succinate in its dichloromethane solution is 27%, and the mixed solution is obtained; the above-mentioned mixed solution is directly coated on a glass plate, and afte...

Embodiment 3

[0035] Add cotton to the hexuronic acid / nitric acid solution, where the solid-to-liquid ratio of cotton to the mixed acid solution is 1:20 g / mL, and the glyoxylic acid (6 mol / L) and sulfuric acid (2 mol / L) in the mixed acid solution The volume ratio of the mixture was 7:1, and the mixture was reacted at 80 °C for 11.5 h. After the reaction was completed, the reaction product was washed with deionized water until it was neutral, and an aldylated cellulose nanocrystal was obtained; under ultrasonic stirring, the aldylated The cellulose nanocrystals of cellulose are added in the acetone solution that is dissolved with polycaprolactone, wherein the mass ratio of the cellulose nanocrystals of aldylation and polycaprolactone is 12:88; The cellulose nanocrystals of aldylation / polycaprolactone The mass fraction of lactone in its acetone solution is 10% to obtain a mixed solution; the above mixed solution is directly coated on a glass plate, and after the product is dried, a spray devic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com