A kind of polystyrene-acrylic acid polymer microsphere and preparation method thereof

A technology of acrylic polymer and polystyrene, applied in the field of polymer microsphere science and application, can solve the problems of difficult control of reaction conditions, uneven particle size of microspheres, and irregular arrangement of space matrix, etc., and achieve great application potential , Regular and orderly structure, low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

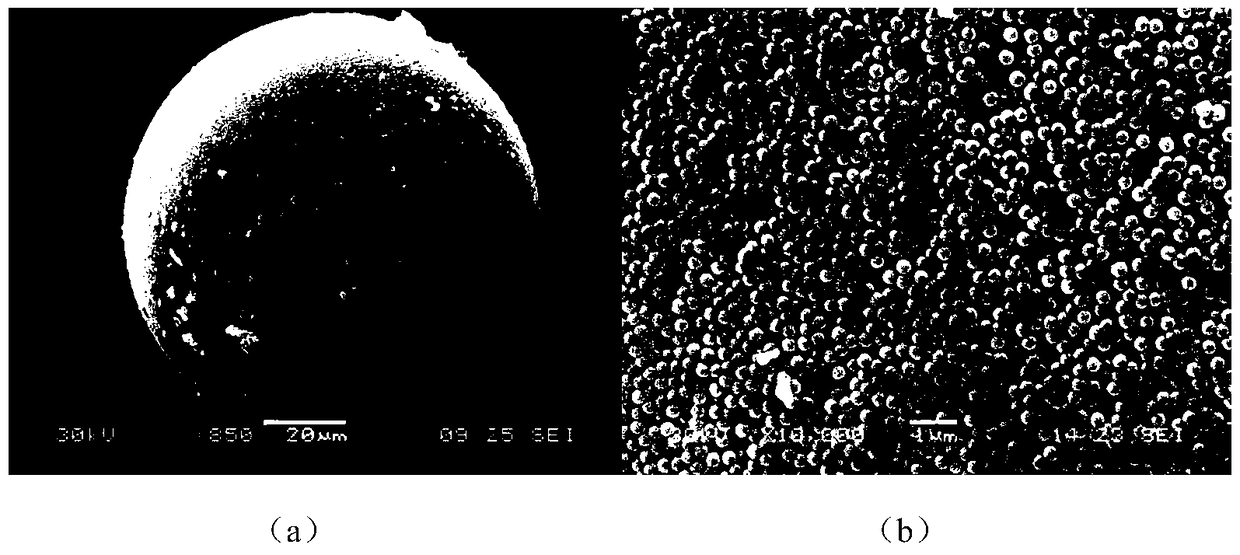

Embodiment 1

[0025] A polystyrene-acrylic acid polymer microsphere is prepared by the following method:

[0026] (1) Preparation of polystyrene-acrylic acid latex particles: styrene and acrylic acid are mixed according to the molar ratio of 20:1, after fully stirring and mixing at room temperature, add sodium dodecylbenzenesulfonate (dodecylbenzenesulfonate) The mass ratio of sodium alkylbenzene sulfonate to styrene monomer is 0.02:1) for pre-emulsification, and then slowly increase the temperature. During the temperature rise from 50°C to 80°C, add 3 parts of potassium persulfate solution dropwise in 3 times , and then the temperature was raised to 85°C, kept for 2 hours, and then 4 parts of potassium persulfate solution was added dropwise, and the reaction was continued for 1 hour. After the reaction, the product was washed by centrifugation to obtain polystyrene-acrylic acid latex particles, which were white solid powder ; The mass ratio of the quality of potassium persulfate in the 7 p...

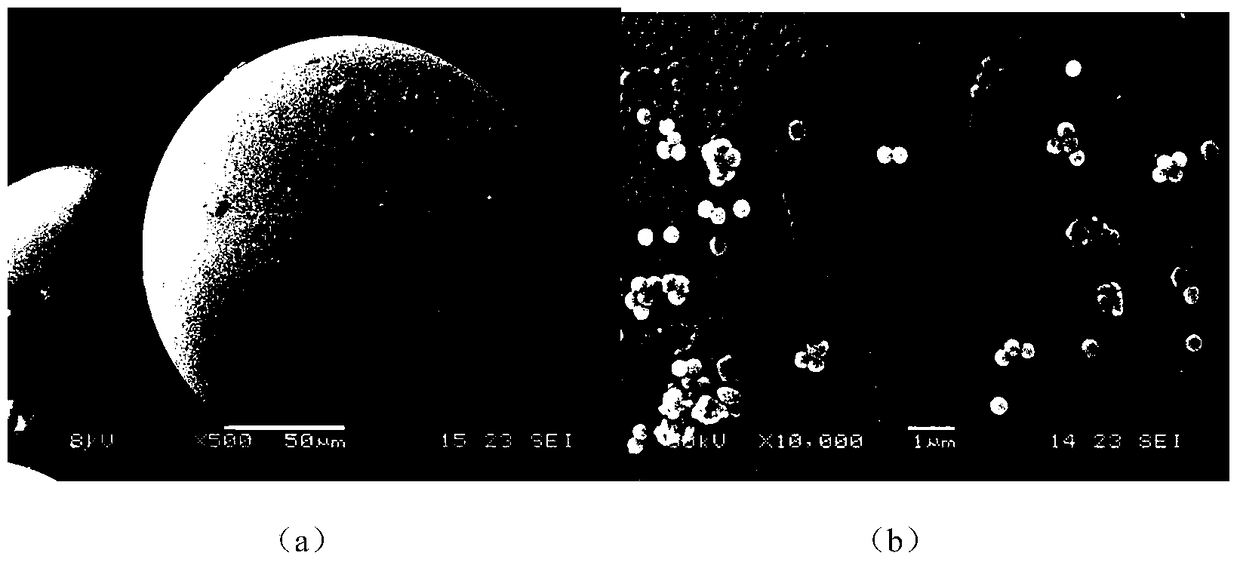

Embodiment 2

[0030] A polystyrene-acrylic acid polymer microsphere is prepared by the following method:

[0031] (1) Preparation of polystyrene-acrylic acid latex particles: styrene and acrylic acid are mixed according to the molar ratio of 30:1, after fully stirring and mixing at room temperature, add sodium dodecylbenzenesulfonate (dodecylbenzenesulfonate) The mass ratio of sodium alkylbenzenesulfonate to styrene monomer is 0.02:1) for pre-emulsification, and then slowly increase the temperature. During the temperature rise from 50°C to 80°C, add 3 parts of ammonium persulfate solution dropwise in 3 times , then the temperature was raised to 85°C, kept for 2 hours, and then 4 parts of ammonium persulfate solution was added dropwise, and the reaction was continued for 2 hours. After the reaction, the product was washed by centrifugation to obtain polystyrene-acrylic acid latex particles, which were white solid powder ; The quality of ammonium persulfate in the 7 parts of ammonium persulfa...

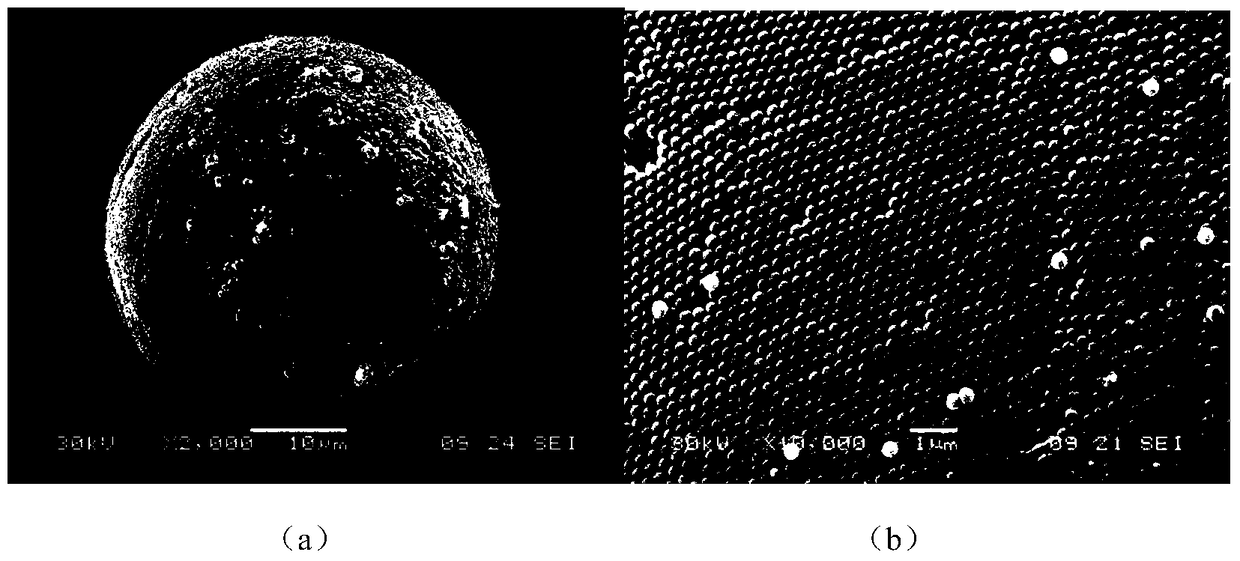

Embodiment 3

[0035] A polystyrene-acrylic acid polymer microsphere is prepared by the following method:

[0036](1) Preparation of polystyrene-acrylic acid latex particles: styrene and acrylic acid are mixed according to the molar ratio of 40:1. After fully stirring and mixing at room temperature, add sodium dodecylsulfonate (dodecane The mass ratio of sodium sulfonate to styrene monomer is 0.02:1) for pre-emulsification, and then slowly raise the temperature. During the temperature rise from 50°C to 80°C, add 3 parts of azobisisobutyronitrile dropwise in 3 times solution, then the temperature was raised to 85°C, and the reaction was kept for 2.5 hours, and then 4 parts of azobisisobutyronitrile solution was added dropwise, and the reaction was continued for 1 hour. After the reaction, the product was centrifugally washed with water to obtain polystyrene-acrylic acid latex particles , is a white solid powder; the mass ratio of azobisisobutyronitrile mass to styrene monomer in the 7 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com