A lithium-rich/3d graphene composite cathode material

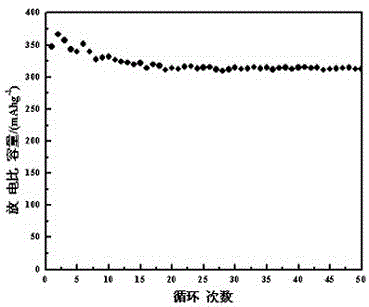

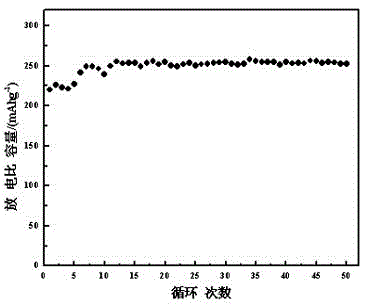

A composite cathode material and graphene composite technology, applied in the field of electrochemistry, can solve the problem of low discharge specific capacity performance of the material, and achieve the effects of good cycle stability, good cycle performance, and good repeatability of mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

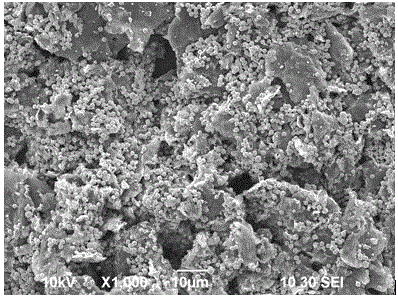

[0036] A lithium-rich / 3D graphene composite positive electrode material, the molecular formula of the composite positive electrode material is Li 1.2 mn 0.54 co 0.13 Ni 0.13 o 2 / 3D graphene; it is obtained by the following steps:

[0037] 1) Prepare a mixed aqueous solution A of manganese acetate, nickel acetate and cobalt acetate according to the molar ratio of Mn, Ni and Co at 0.54:0.13:0.13 (the sum of the molar concentrations of Mn, Ni and Co is 1 mol / L), Prepare a urea aqueous solution B with a concentration of 5 mol / L, then add solutions A and B to a three-necked bottle pre-installed with a uniformly dispersed graphene oxide aqueous solution at a volume ratio of 1:8, and mix to form a precursor solution;

[0038] 2) Heat the precursor solution, and add dimethyl sulfoxide to adjust the temperature to 107°C during the heating process, reflux for 10 hours, cool to room temperature after the reaction, age for 1 hour, filter with suction, and use absolute ethanol and dei...

Embodiment 2

[0043] A lithium-rich / 3D graphene composite positive electrode material, the molecular formula of the composite positive electrode material is Li 1.3 mn 0.35 co 0.14 Ni 0.21 o 2 / 3D graphene; it is obtained by the following steps:

[0044] 1) Prepare a mixed aqueous solution A of manganese nitrate, cobalt nitrate and nickel nitrate according to the molar ratio of Mn, Co and Ni at 0.35:0.14:0.21 (the sum of the molar concentrations of Mn, Co and Ni is 1 mol / L), Prepare an aqueous urea solution B with a concentration of 5 mol / L, then add solutions A and B to a three-neck bottle pre-installed with a uniformly dispersed 3D graphene aqueous solution at a volume ratio of 1:3, and mix to form a precursor solution;

[0045] 2) Heating the precursor solution, and adjusting the temperature to 97°C by adding DMSO during the heating process, reflux reaction for 20h, cooling to room temperature after the reaction, aging for 1h, suction filtration, washing with absolute ethanol and deio...

Embodiment 3

[0049] A lithium-rich / 3D graphene composite positive electrode material, the molecular formula of the composite positive electrode material is Li 1.4 mn 0.3 co 0.06 Ni 0.24 o 2 / 3D graphene; it is obtained by the following steps:

[0050] 1) Prepare a mixed aqueous solution A of manganese chloride, cobalt chloride and nickel chloride according to the molar ratio of Mn, Co and Ni at 0.3:0.06:0.24 (the sum of the molar concentrations of Mn, Co and Ni is 1mol / L), prepare urea aqueous solution B with a concentration of 5mol / L, and then add solutions A and B to a three-necked bottle pre-installed with a uniformly dispersed 3D graphene aqueous solution at a volume ratio of 1:4, and mix to form a precursor solution;

[0051] 2) Heat the precursor solution, and adjust the temperature to 117°C by adding NMP during the heating process, reflux for 8 hours, cool to room temperature after the reaction, age for 1 hour, suction filter, and alternately wash with absolute ethanol and deio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com