Whole timber firelog impregnated with combustible material

a firelog and combustible material technology, applied in biofuels, waste based fuels, fuels, etc., can solve the problems of reducing the number of binder waxes that can be used, restricting the choice of binder waxes or blends of binder waxes, and high cost of producing synthetic firelogs. , to achieve the effect of reducing manufacturing costs, increasing energy density, and reducing the number of binder waxes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

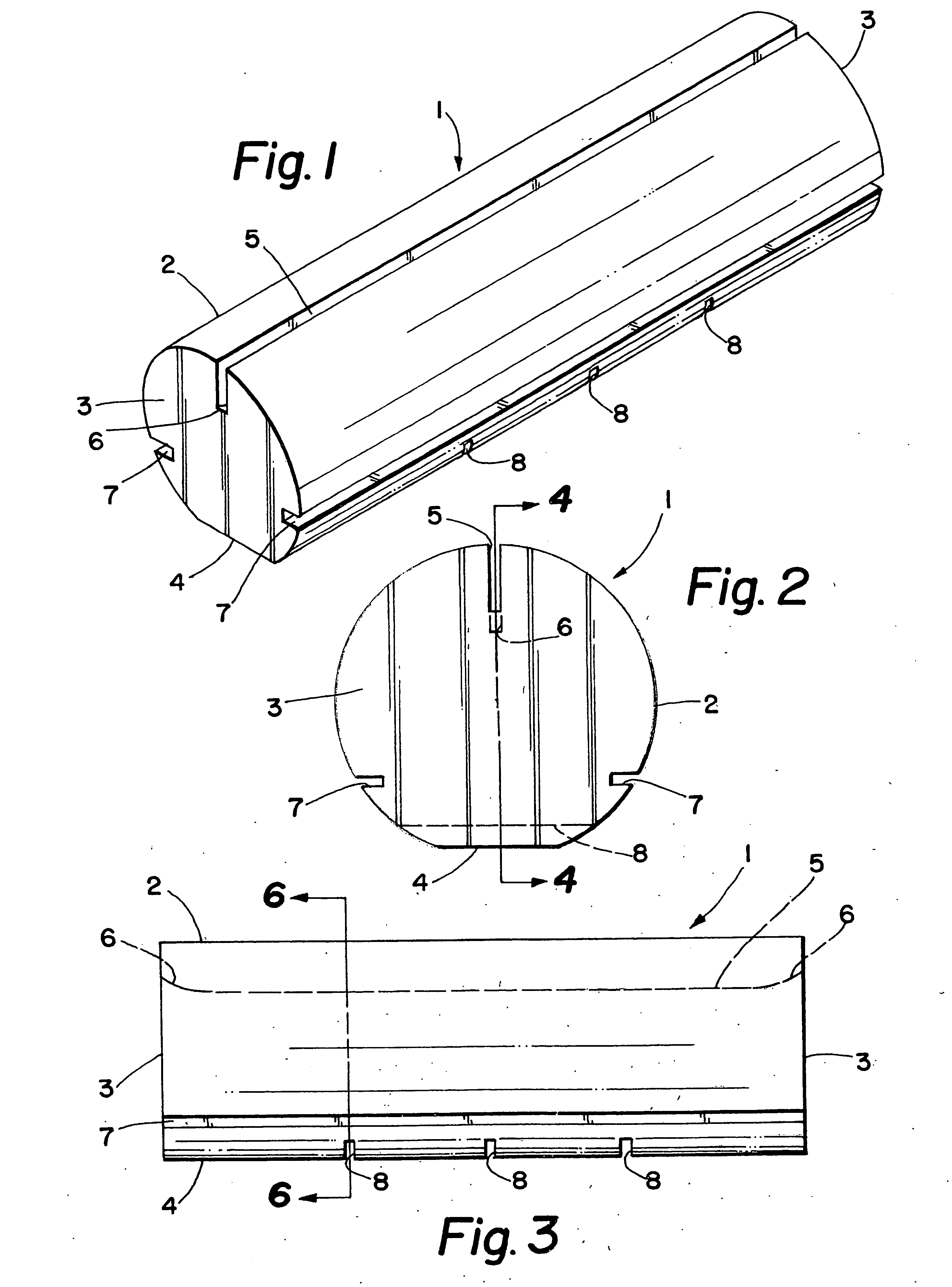

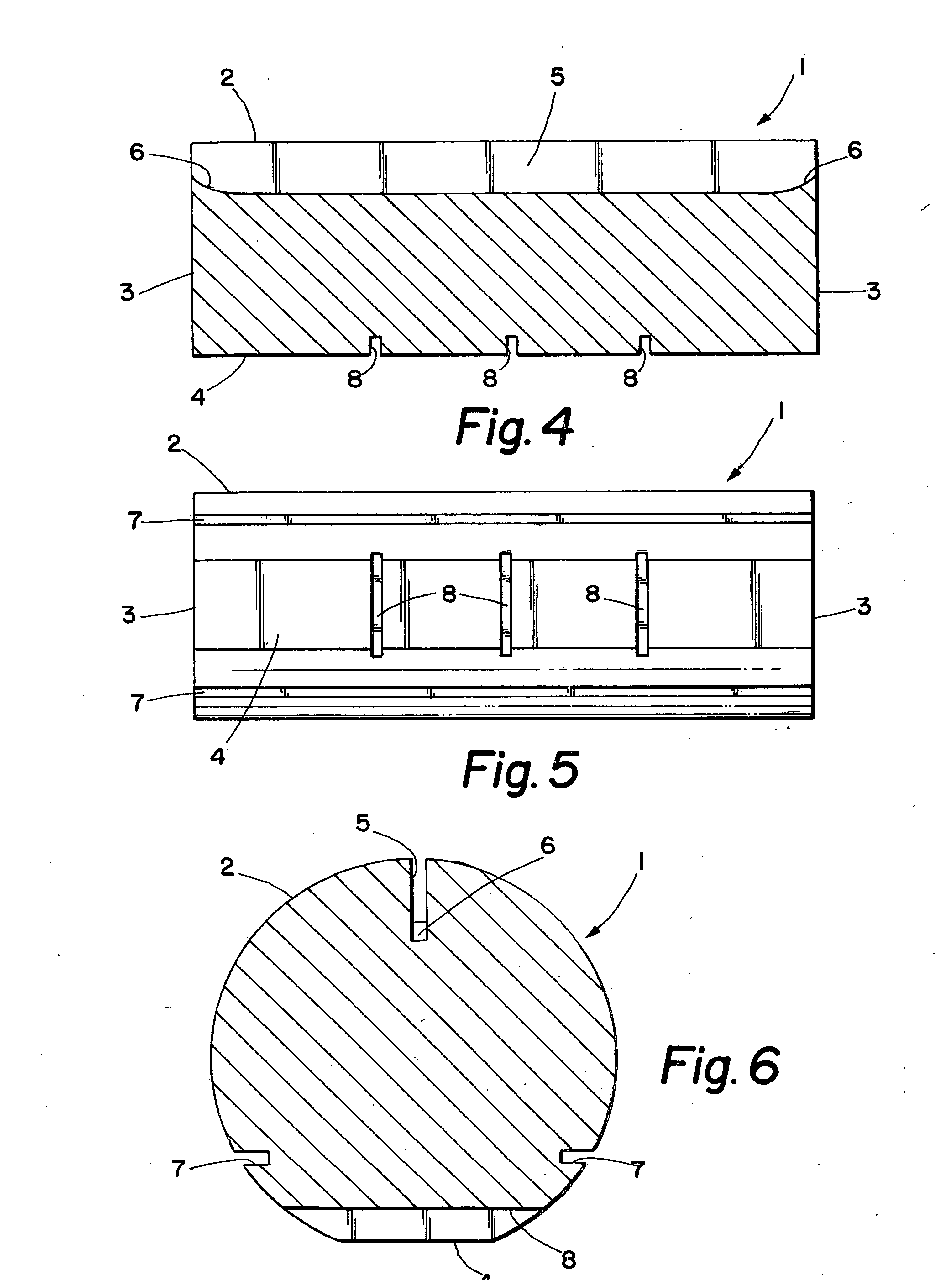

[0036] The applicants' have developed a new and improved firelog 1 that is based on a whole piece of timber, as most easily seen in FIG. 1. Although a shaped log is shown in the figures accompanying this application, the timber need not be pre-cut or shaped, and may even still retain the original bark during use and the impregnating process. For the purpose of this patent, an “upright” log shall be a log as shown in FIG. 6, where a flat bottom edge 4 is at the bottom.

[0037] Firelog 1, as shown in FIG. 1, is through a process to be described impregnated with additional combustible fuel additive. Various combustible fluids or combinations thereof may be used as fuel, including but not limited to alcohols (i.e. methanol (typical energy density: 56,000-65,000 BTUs / gallon), ethanol (76,000-82,000 BTUs / gallon), isopropanol), short chain hydrocarbons (i.e. hexane, heptane, gasolines (typical energy density: 110,000-120,000 BTUs / gallon) and diesel (typical energy density 130,000 BTUs / gallo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com