Switch grass fuel objects with high heat output and reduced air emissions designed for large-scale power generation

a technology of high heat output and power generation, applied in the direction of biofuels, fuels, waste based fuels, etc., can solve the problems of increasing cost, cumulative environmental impact, and decreasing supply, and achieve the effect of reducing air emissions and heating heat valu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

Switch Grass Fuel Object

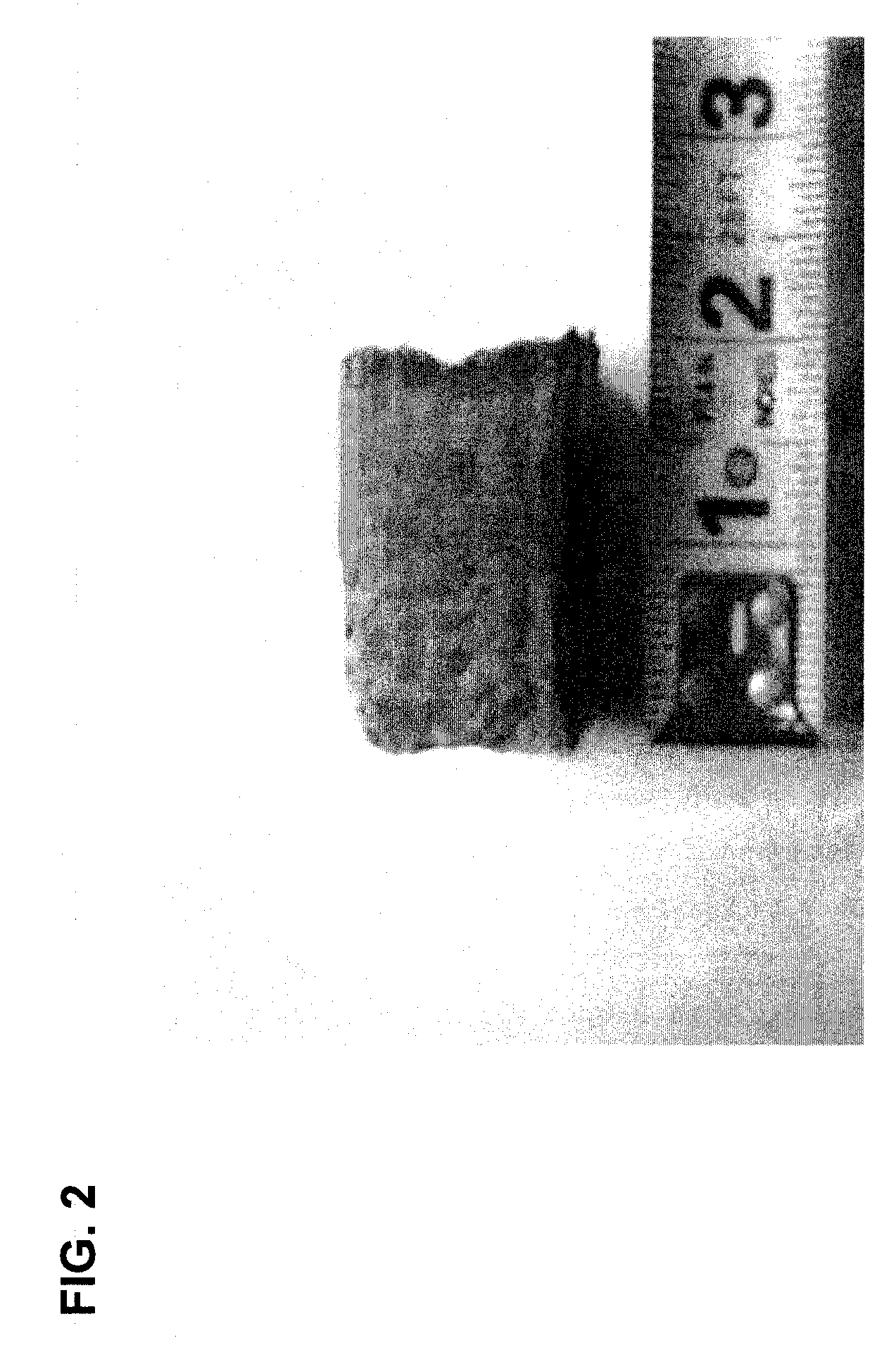

[0042]A fuel object derived from switch grass and wood was produced and was substantially free of coal. The switch grass fuel object was substantially cylindrical in shape with a length of 5.4 cm and a diameter of 2.6 cm.

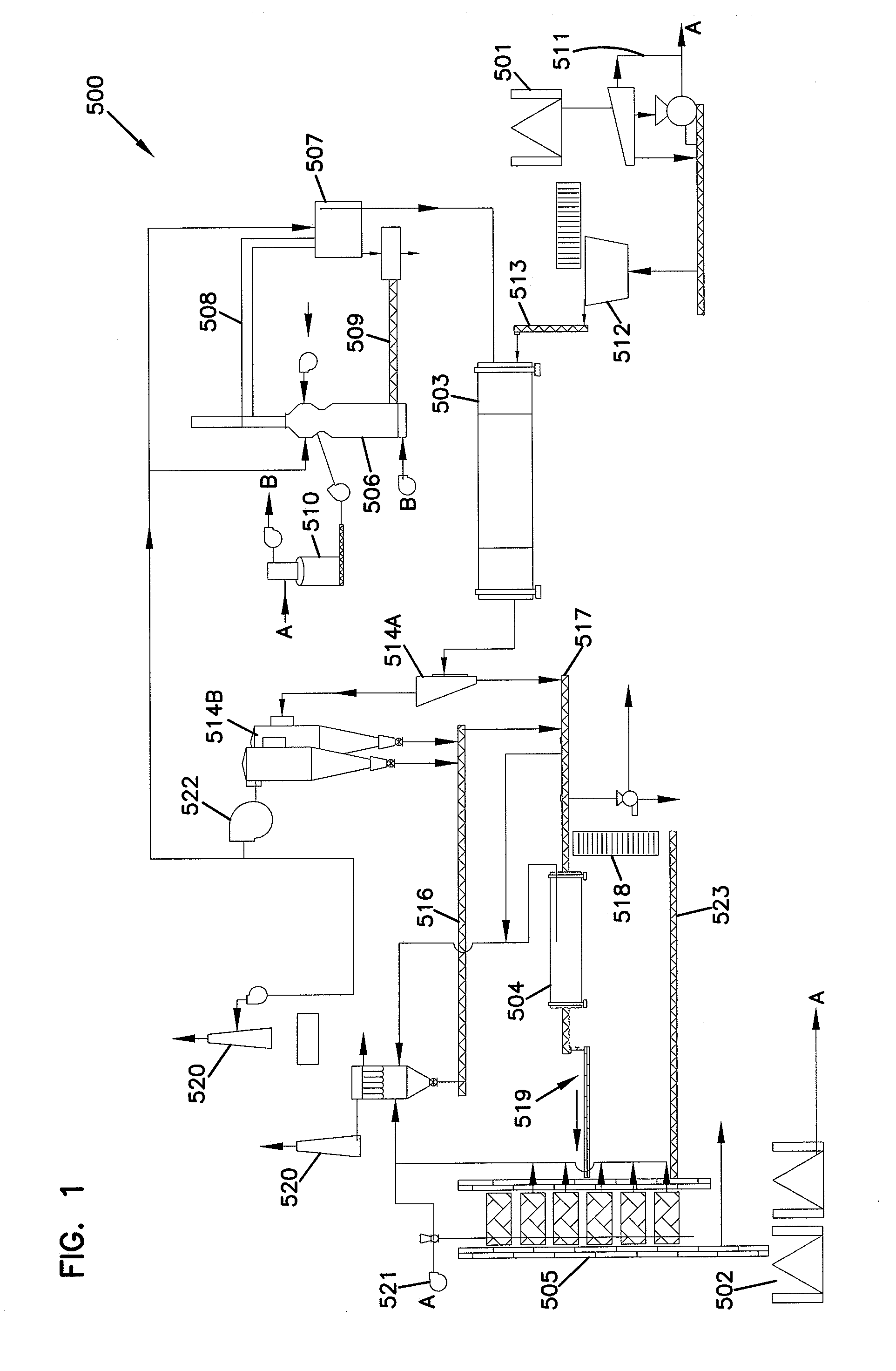

[0043]FIG. 1 shows an embodiment of the invention.

Volume14.04 cm3Moisture content 8.27 wt. %Amount of particulate derived from 63.2 wt. %switch grass-fiber size 80 to 25,000micronsAmount of particulate derived from 34.4 wt. %wood fiber-fiber size 100 to 30,000micronsSodium bicarbonate (inorganic base) 2.4 wt. %

[0044]In testing, this switch grass fuel object provided about 7,386 BTU / pound (lb.).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com