Environmentally friendly fire logs

a fire log and environment-friendly technology, applied in biofuels, waste-based fuels, fuels, etc., can solve the problems of unsatisfactory consumer use, easy absorbed into combustible materials, and low viscosity and molecular weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

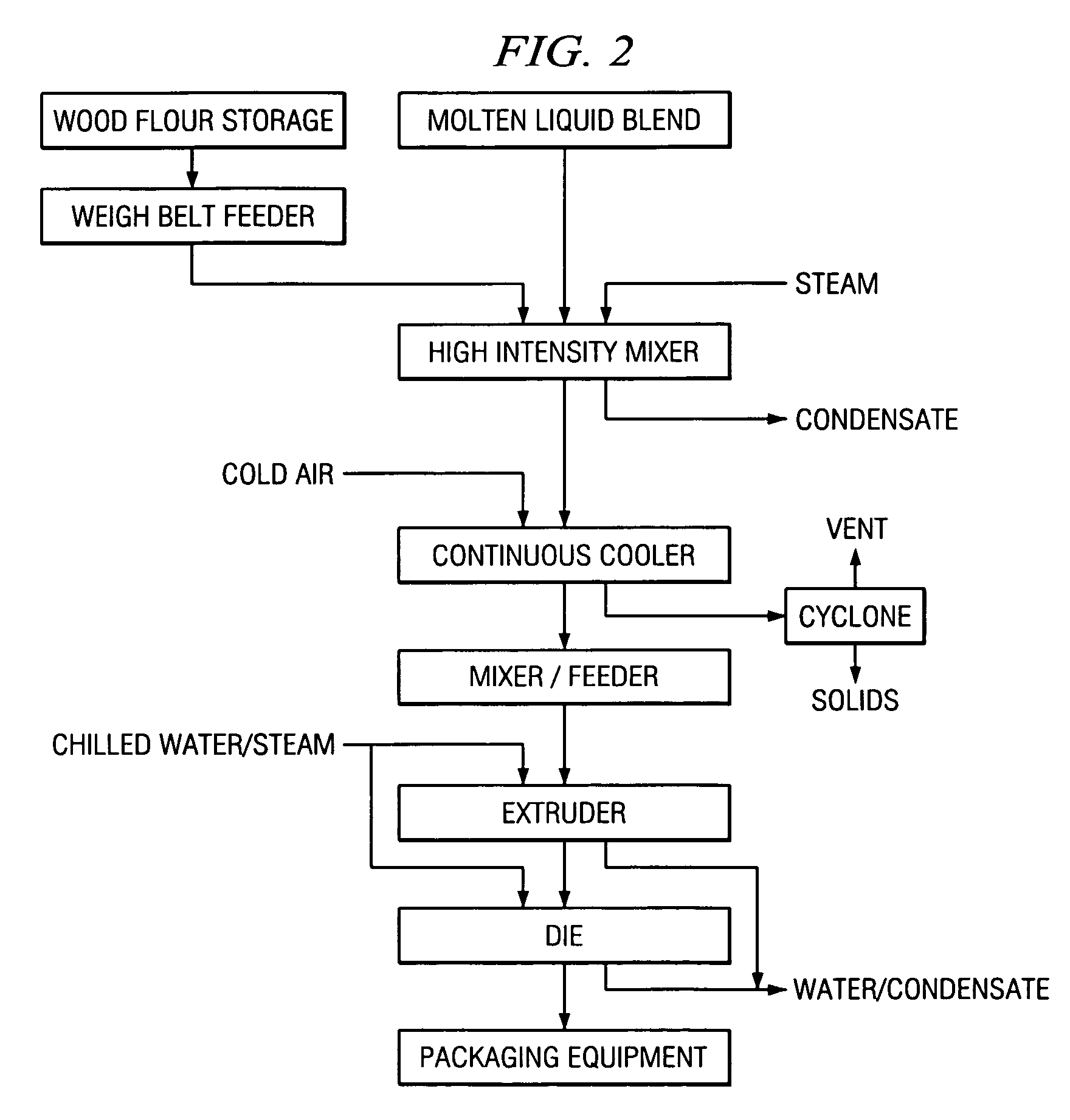

Method used

Image

Examples

examples

[0052] Both laboratory and commercial scale tests were performed to evaluate the burn characteristics of the logs. A description of the laboratory scale test stand follows: after a particular log recipe was mixed and a log was extruded according to the processes described herein, the log was subjected to a burn test. The log was lit on both bottom ends of the log. Burn characteristics were observed and noted as they occurred. Noted burn characteristics may include the ease of ignition, the flame (size and movement), heat generation, log integrity (drip or breakage), level of smoke generation, ash produced, and flame propagation. Total burn time was noted. The logs were also measured or observed in relation to total weight, log density, log durability upon handling, hardness, heat exposure, and general appearance (presence of cracks, swelling and the like).

exemplary example i

[0055] A 5 pound fire log wax made of about 48% wood flour and about 52% molten liquid blend. The liquid blend was composed of about 80% modified (saponified, neutralized, distilled, and acidulated) tall oil pitch residue and about 20% polyethylene wax and had a viscosity of approximately 29 centipoise at 300 degrees Fahrenheit and a drop melt point of about 223 degrees Fahrenheit. The log was wrapped in a paper wrapper. The wrapper was lit in order to ignite the log at 6:45 a.m. The log became totally engulfed in flames at 6:50 a.m. and the log burned until 10:15 a.m.

exemplary example ii

[0056] A 6 pound fire log was produced by extrusion and was composed of about 44% wood flour and about 56% molten liquid blend. The liquid blend was composed of about 75% modified (saponified, neutralized, distilled, and acidulated) tall oil pitch residue and about 25% polyethylene wax. The liquid blend had a viscosity of approximately 23 centipoise at 300 degrees Fahrenheit and a drop melt point of about 228 degrees Fahrenheit. The log was wrapped in a paper wrapper and at 8:30 a.m. lit by lighting the paper wrapper. The log became totally engulfed in flames by 8:37 a.m. and burned until 12:25 p.m. Flame height was very good during about 95% of the burn time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com