Two-stage gas flow-fluidized bed drying process and apparatus with nitogen circulated adipic acid and overheated steam

A technology of superheated steam and drying method, which is applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., which can solve the problems of large exhaust gas and dust emissions, easy combustion and explosion, and pollution of adipic acid, etc., and achieve reduction Heat loss, not easy to stick to the wall, long residence time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

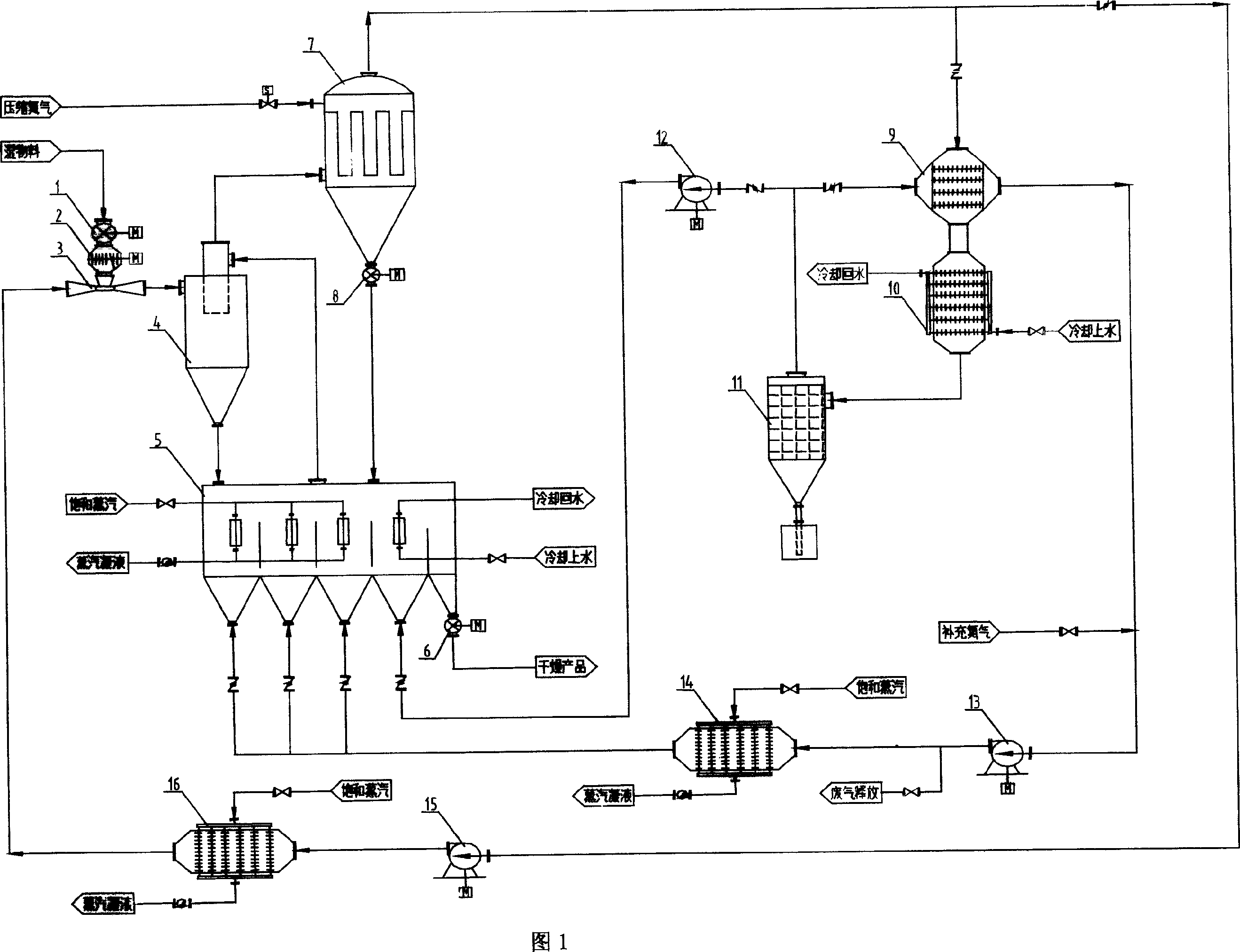

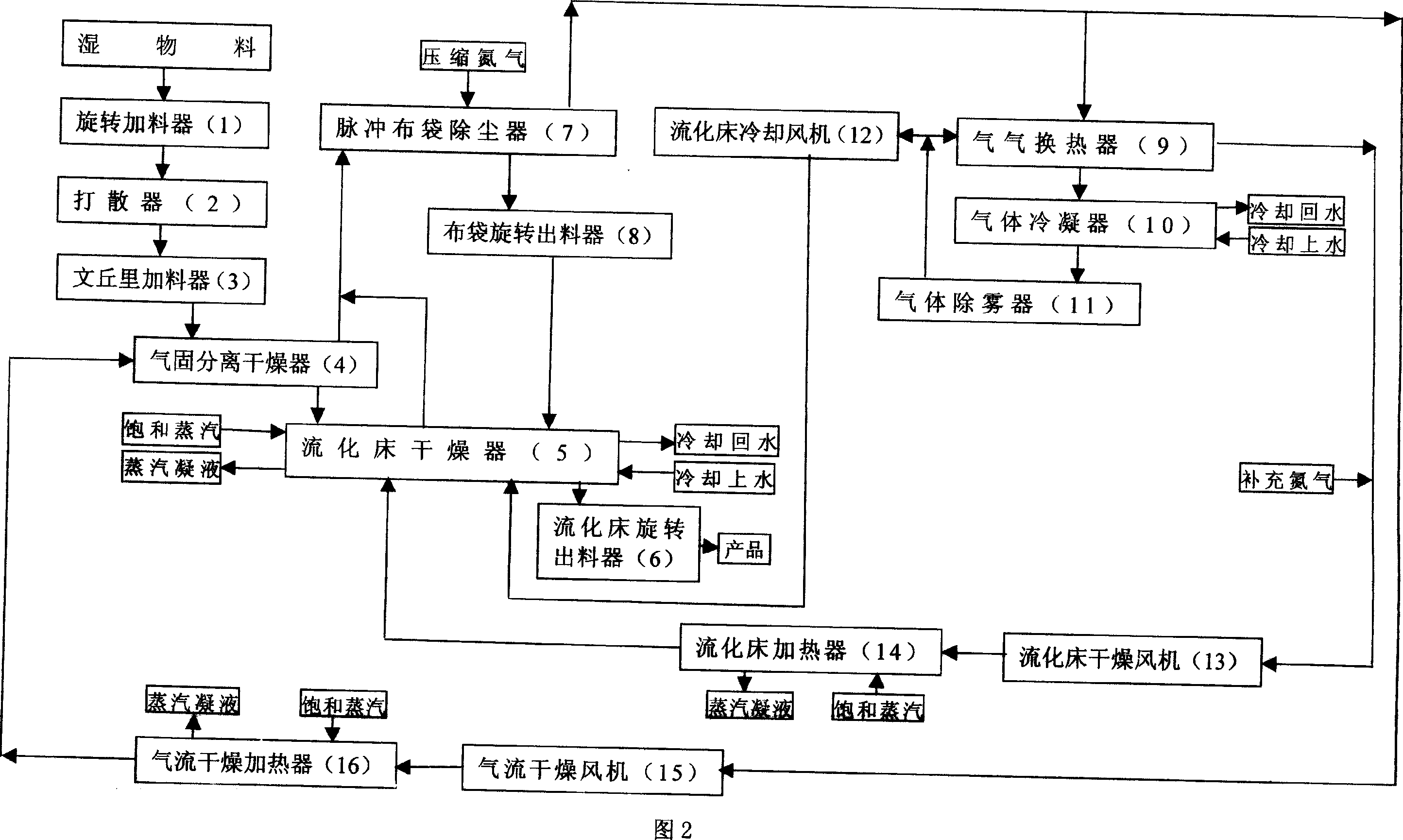

[0039]Adipic acid wet material with a moisture content of 10-15% enters the material disperser 2 from the rotating feeder 1, and the agglomerated viscous materials are dispersed under the action of the disperser, and enter the Venturi at the side entrance Under the action of the negative pressure generated by the hot nitrogen of the feeder 3, adipic acid is sucked into the venturi feeder 3 from the bottom of the material disperser 2, and at the same time, the hot nitrogen and adipic acid form a gas at the side outlet of the venturi feeder 3 A homogeneous mixture of solids, adipic acid is forced into the gas-solid separation dryer 4 after being accelerated by hot nitrogen. The gas-solid separation dryer 4 has a single-cylinder structure, which has the dual functions of separation and pre-drying. At the same time as the solid separation, the constant-speed air flow is pre-dried instantaneously. After the gas-solid separation and pre-drying are completed, the hot nitrogen with a smal...

Embodiment 2

[0043] Adipic acid wet material with a moisture content of 10-15% enters the material disperser 2 from the rotating feeder 1, and the agglomerated viscous materials are dispersed under the action of the disperser, and enter the Venturi at the side entrance Under the action of the negative pressure generated by the hot nitrogen of the feeder 3, adipic acid is sucked into the venturi feeder 3 from the bottom of the material disperser 2, and at the same time, the hot nitrogen and adipic acid form a gas at the side outlet of the venturi feeder 3 A homogeneous mixture of solids, adipic acid is forced into the gas-solid separation dryer 4 after being accelerated by hot nitrogen. The gas-solid separation dryer 4 has a double-cylinder structure, which has the dual functions of separation and pre-drying. At the same time of solid separation, an instantaneous pre-drying of airflow at constant speed is carried out. After the gas-solid separation and pre-drying are completed, hot nitrogen wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com