Separator rotary feeder and method of using the same

A feeder and rotor technology, applied in the field of devices for separating granular materials and supplying granular materials, can solve the problems of increasing the vertical height of the material processing system, interfering with operations, and complex structural design.

Active Publication Date: 2010-12-15

UNIVATION TECH LLC

View PDF8 Cites 28 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Vibration may interfere with the operation of precision solids metering or feeding devices

Also, since these material handling systems are often gravity fed systems, the installation of screens can also increase the vertical height of the material handling system, increase construction costs and complicate structural design

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

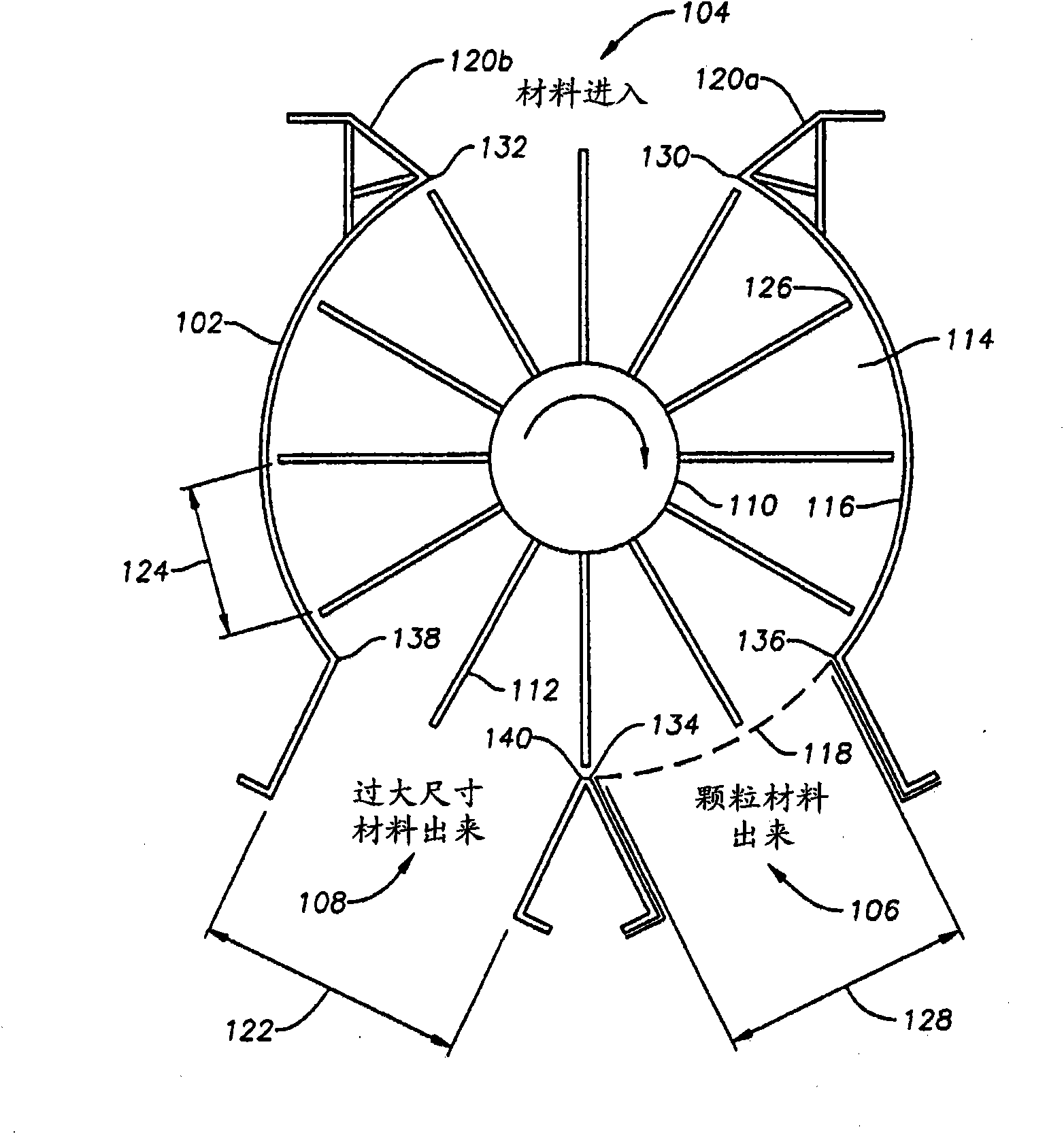

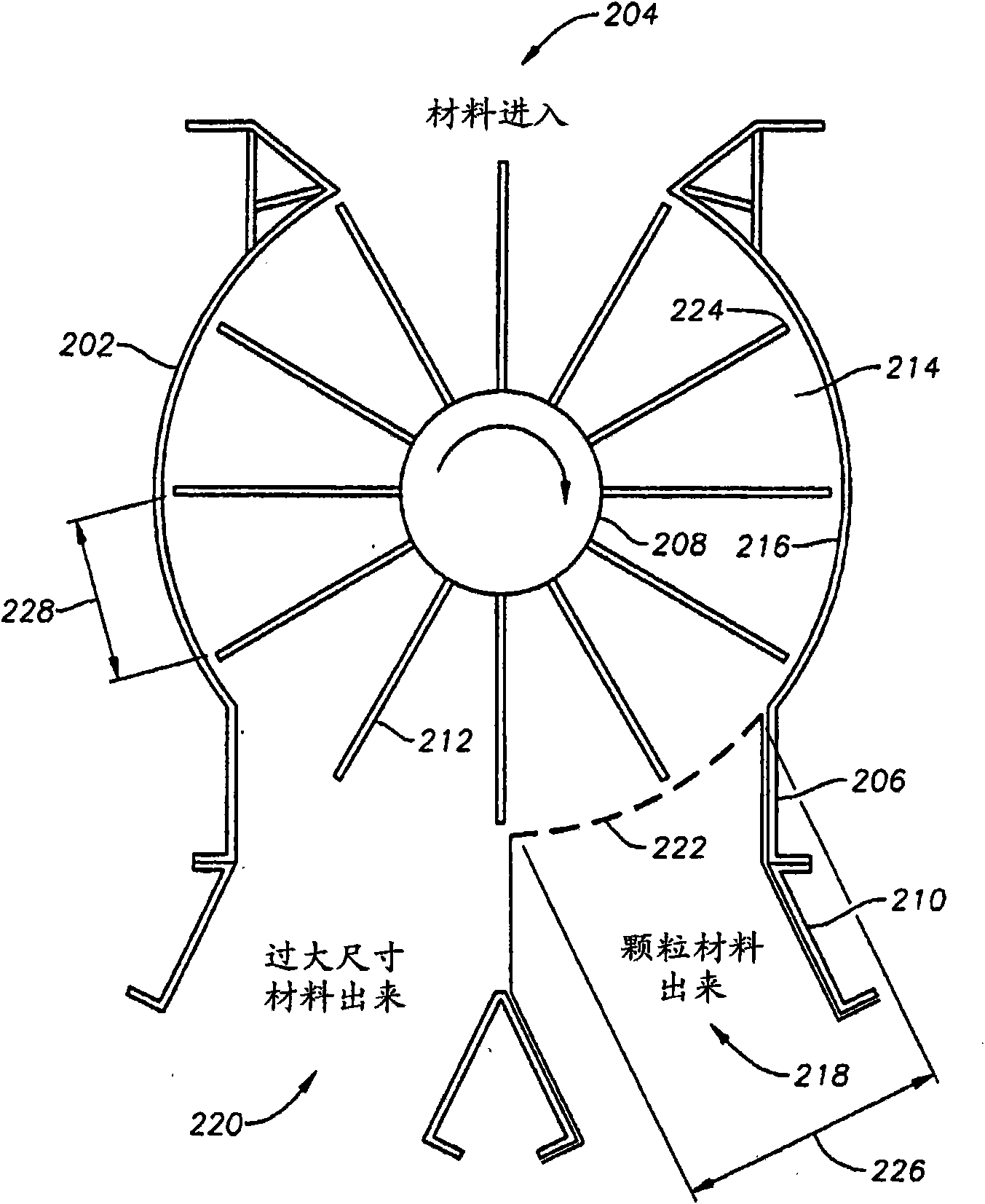

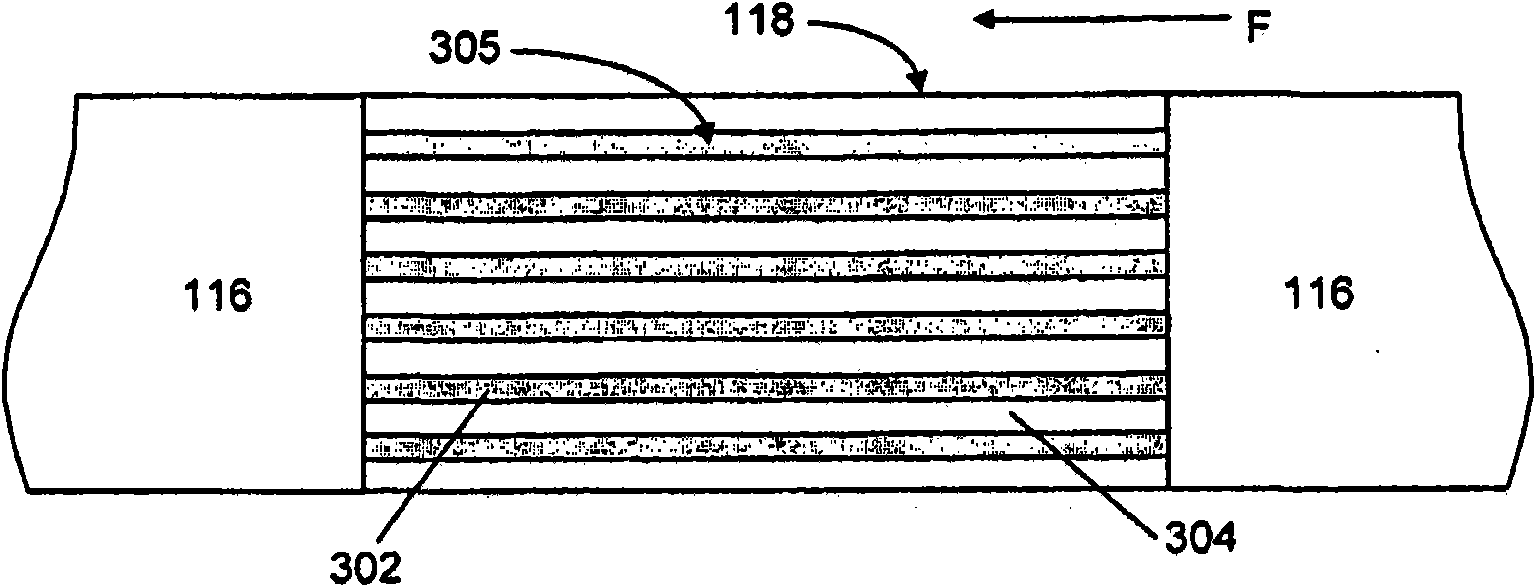

A rotary feeder for feeding a particulate material including: a cylindrical housing comprising a feeder inlet, a first feeder outlet, and a second feeder outlet; a rotor mounted in the cylindrical housing including a plurality of substantially impeller blades defining a plurality of circumferentially spaced pockets alignable with the feeder inlet, first feeder outlet, and second feeder outlet, and adapted to sweep a wall of the cylindrical housing as the rotor rotates in the cylindrical housing; a device for rotating the rotor; and a separating screen in the first feeder outlet to substantially prevent oversize material from exiting through the first feeder outlet, wherein each of the plurality of circumferentially spaced pockets will align with the feeder inlet to receive therein a particulate material and an oversize material through the feeder inlet, rotate in the cylindrical housing to align with the first feeder outlet and discharge the particulate material therefrom, and rotate in the cylindrical housing to align with the second feeder outlet after alignment with the first feeder outlet and discharge the oversized material therefrom is provided as well as a method of using the same.

Description

Cross References to Related Applications This application claims the benefit of No. 61 / 008868, filed December 20, 2007, which is hereby incorporated by reference in its entirety. technical field The present invention generally relates to apparatus and methods for supplying particulate material. More specifically, the present invention relates to the use of a rotary feeder to feed particulate material into a material handling system. The present invention also generally relates to apparatus and methods for separating particulate material in rotary feeders. Background technique Many materials such as plastics, wood chips, grains, shredded waste, granular products, etc. separate materials are processed in material handling equipment using rotary airlock meters or rotary feeders. For example, the separated material may be fed to other solids handling equipment, such as mixers, blenders, or various types of handling vessels. To prevent pressurized gas from escaping or air f...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B07B1/20B07B13/07B07B13/16B65G53/46

CPCB07B1/20B07B13/16B07B13/07B65G53/4633

Inventor W·J·布里克利R·L·福斯

Owner UNIVATION TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com