Full-negative-pressure powder processing system

A processing system and full negative pressure technology, applied in the field of full negative pressure powder processing system, can solve problems such as dust leakage and pollution, achieve uniform and smooth flow, improve the working environment and surrounding environment, and have obvious social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

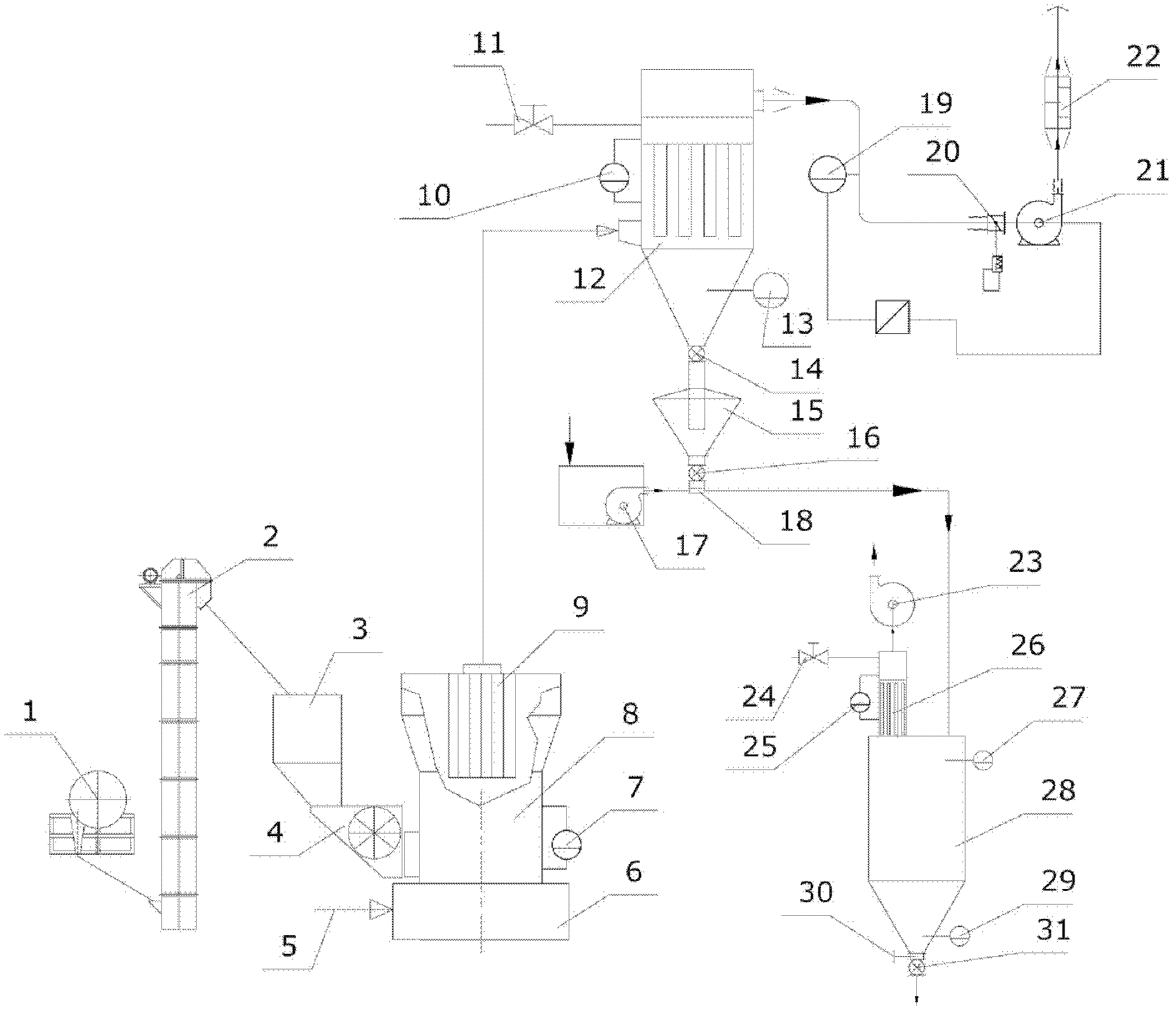

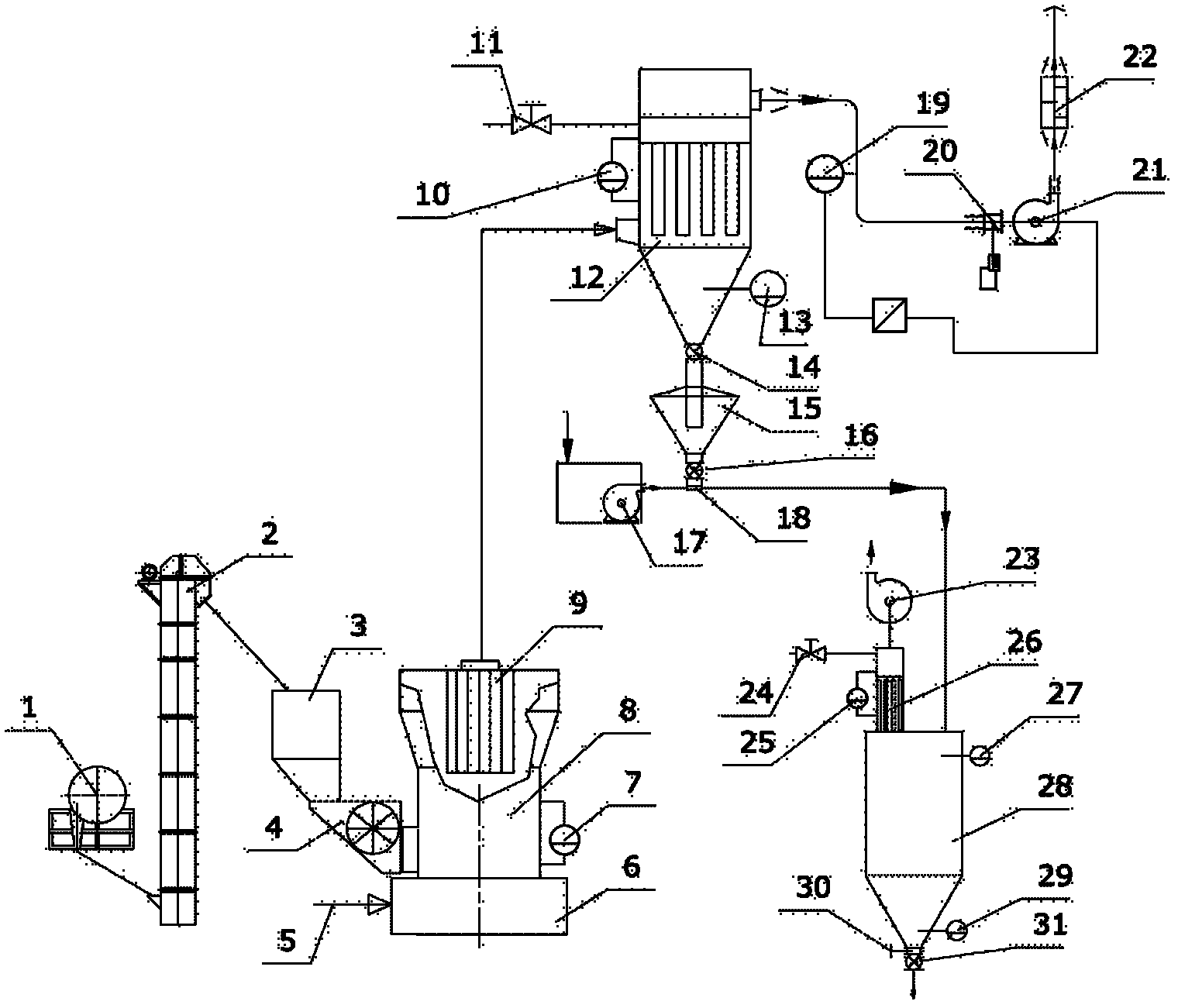

[0017] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0018] See figure 1 , is a schematic diagram of the structure of the embodiment of the full negative pressure powder processing system of the present invention. The jaw crusher 1 crushes the material to a certain particle size, and the material is sent to the hopper 3 through the elevator 2. The material is quantitatively and continuously sent to the main machine 8 of the mill for grinding. The main machine 8 of the mill is equipped with a differential pressure detection device 7. The main machine 8 of the mill maintains a negative pressure state with a pressure difference of 15-20 mbar. The pressure difference value of the main machine 8 of the powder mill controls the feeding amount of the rotary tangential feeder 4, and the ground powder is classified by the classifier 9 placed on the main machine 8 of the mill, and the powder with qualified f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com