Hybrid hydraulic propulsion device

A propulsion device and hydraulic technology, which is applied in the direction of ship propulsion, propulsion components, non-mechanical gear transmission, etc., can solve the problems of not meeting the requirements of use, poor system overload protection ability, low cavitation resistance ability, etc., to achieve The effect of solving hydraulic oil leakage pollution, low noise and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

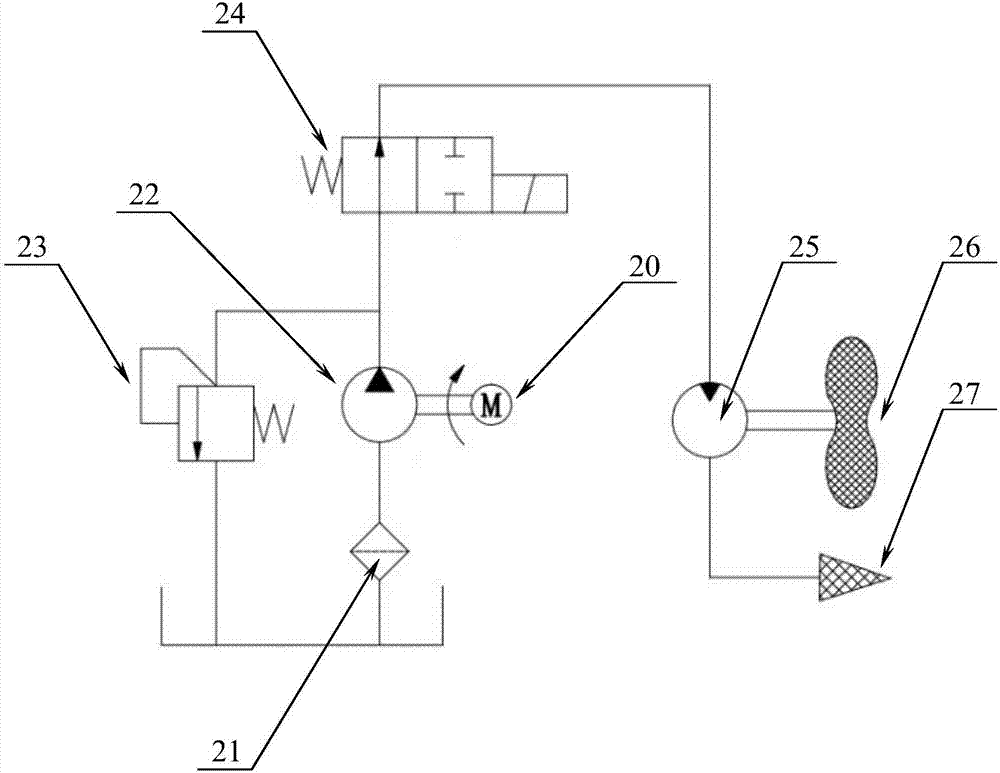

[0016] Example 1, such as figure 2 As shown, this embodiment discloses a fully seawater driven hybrid vector propulsion device, the device includes a displacement hydraulic pump 22 driven by a motor 20, a filter 21 is installed on the water inlet of the displacement hydraulic pump, and a filter 21 is installed on the outlet of the displacement hydraulic pump. A safety valve 23 is installed on the water port to prevent system overload and ensure system safety. In addition, the water outlet of the positive displacement hydraulic pump is also connected to the hydraulic motor 25 through the hydraulic control valve 24, the power output end of the hydraulic motor is connected to the propeller 26, and the water outlet is connected to the nozzle 27 arranged toward the propeller.

[0017] As an alternative, in this embodiment, the positive displacement hydraulic pump is a variable displacement pump, such as a gear pump or a plunger pump, and the rotational speed of the hydraulic motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com