Horizontal-type continuous biochar carbonization device

A technology of biochar and carbonization, which is applied in the fields of biofuel, special carbonization, petroleum industry, etc., can solve the problems of poor charcoal quality, low charcoal output rate, and difficult recycling of combustible gas, so as to improve product quality and slow down Material speed, the effect of preventing air from entering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] Example: Production of biochar using corn stalks

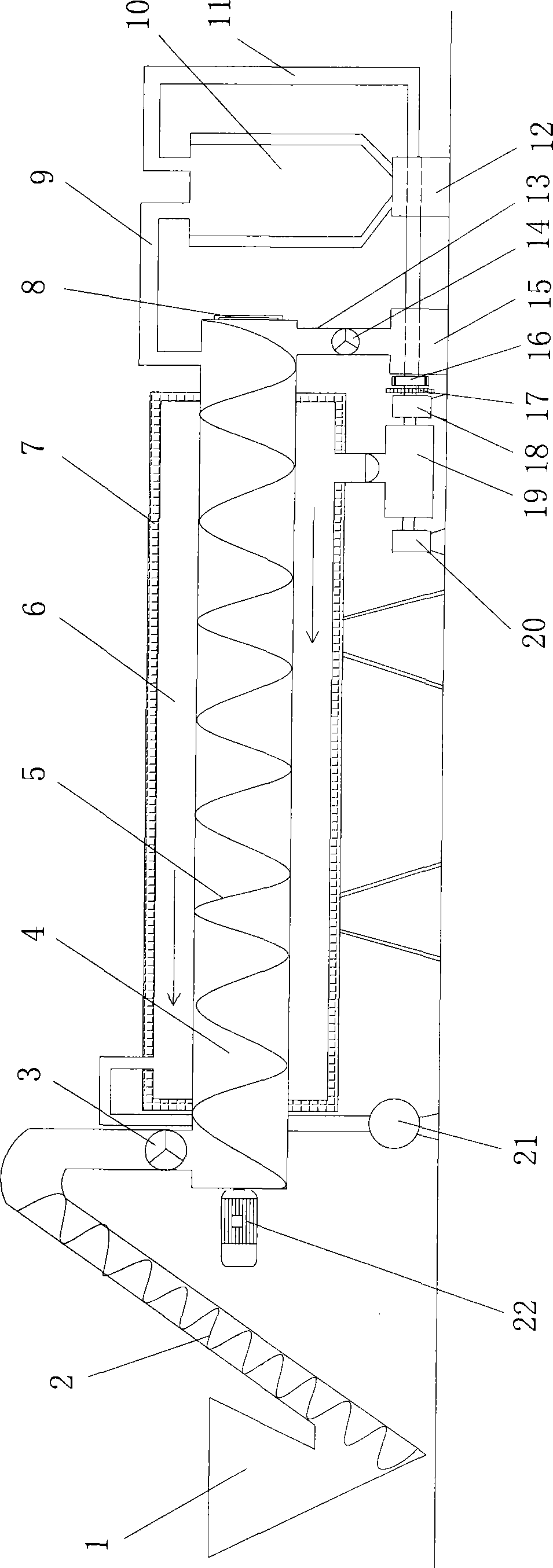

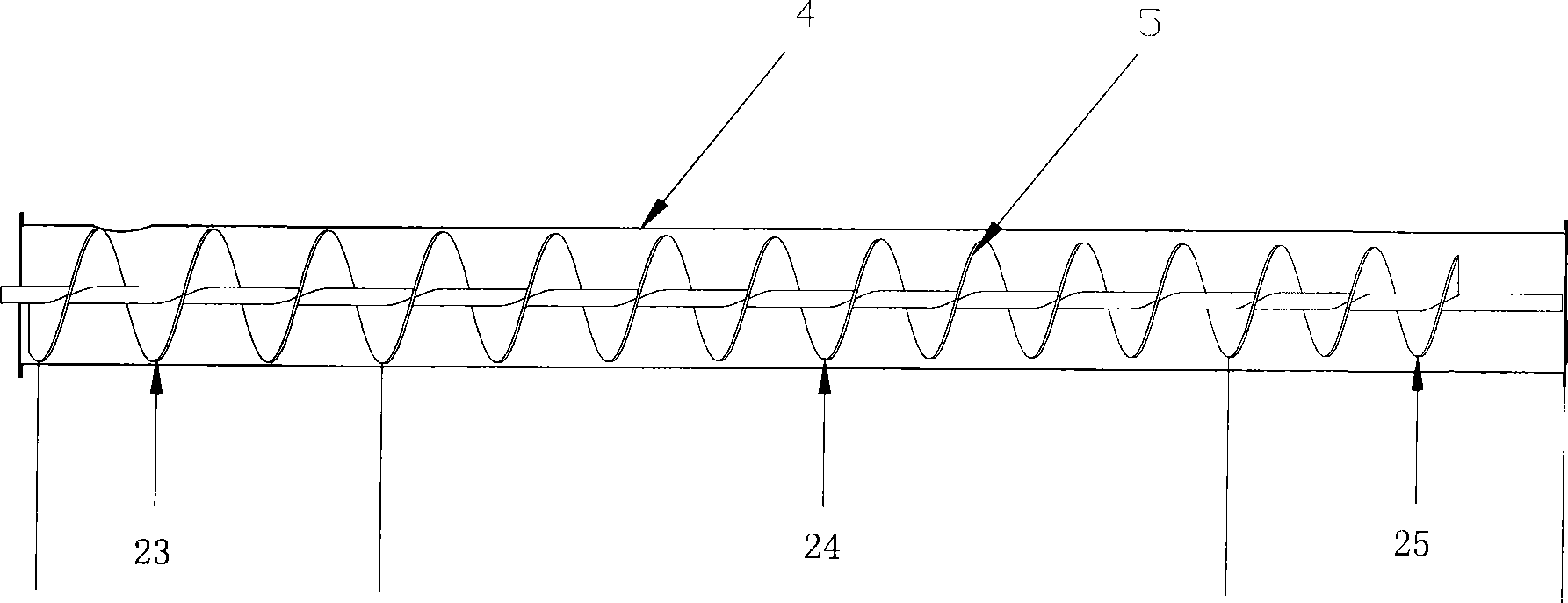

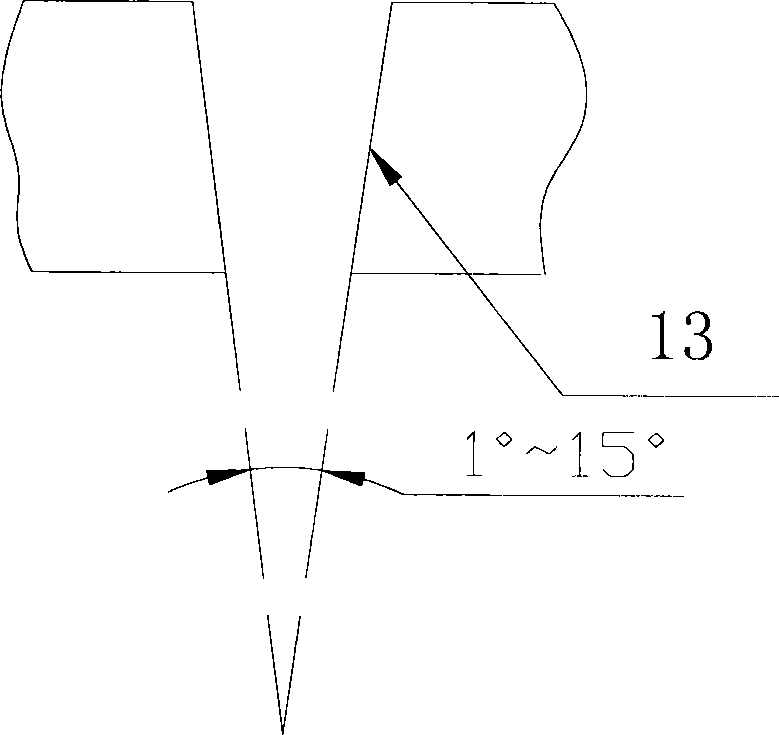

[0038] The horizontal continuous biochar carbonization equipment of the present invention is used to produce biochar, the raw material is corn stalks, the length is about 8-10 mm, the water content is 10-20%, and the density is about 100 kg / m 3 , put it into the feeding hopper, when the material is full, open the feeding screw conveyor and the air shutoff device at the feeding port at the same time, then turn on the screw conveyor in the carbonization chamber, and start the diesel burner when the material slowly enters the carbonization chamber , the material is slowly pushed forward by the screw conveyor, the speed of the material is controlled by the speed regulating motor, and the heating rate can be adjusted. As the material continues to advance, the temperature of the carbonization chamber rises, and the material begins to undergo pyrolysis reaction and is heated to above 250 °C When the temperature rises, the bioc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com