Tapered roller surface defect detection system

A tapered roller and defect detection technology, which is applied in the direction of optical detection of defects/defects, sorting, etc., can solve the problem that the detection results are easily interfered by the material itself and other factors, and the air hole defects on the surface of the rolling body cannot be found, which affects the quality of detection And efficiency and other issues, to achieve the effect of convenient sorting, ensure no dead angle detection, and fast detection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

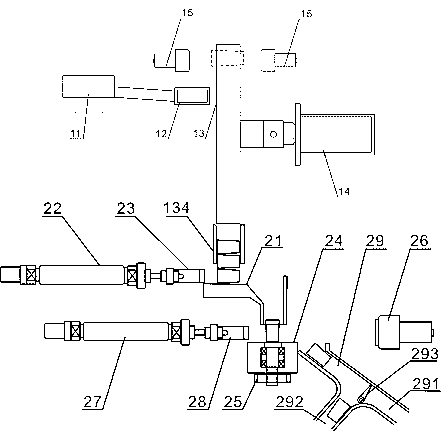

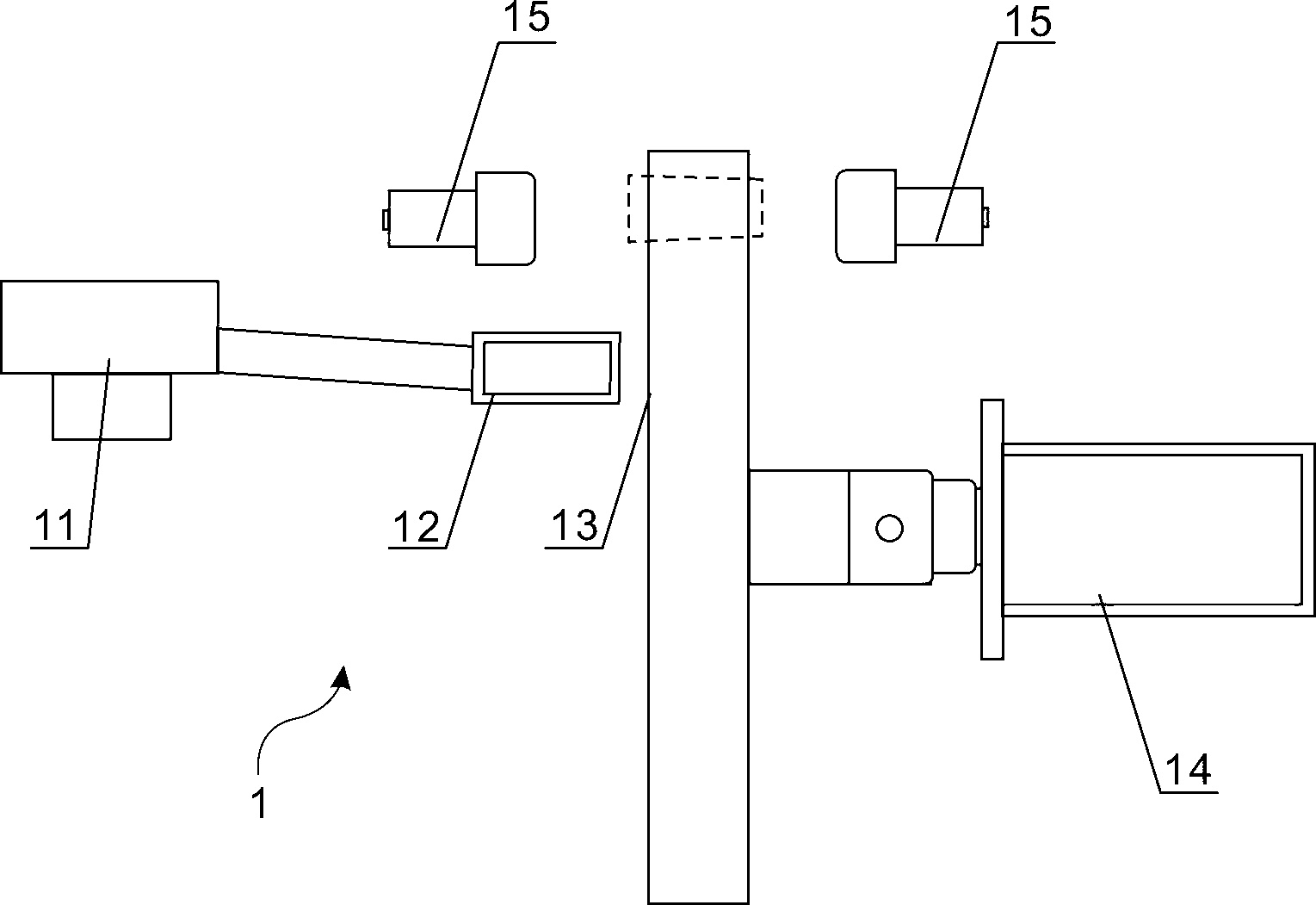

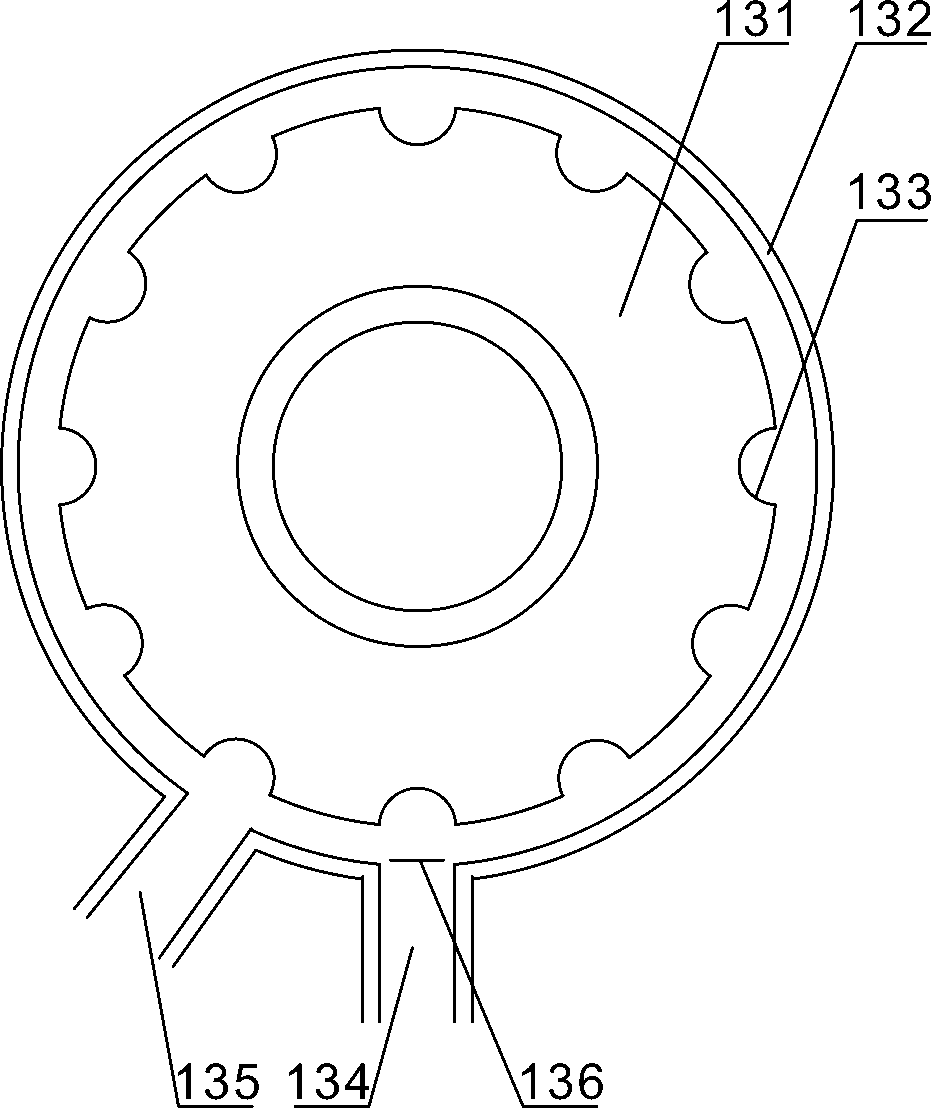

[0027] Such as Figure 1 to Figure 4 As shown, the tapered roller surface defect detection system includes a tapered roller end surface detection mechanism 1 and a side surface detection mechanism 2. The end surface detection mechanism 1 includes a feeder 12, a rotary feeder 13 and an image acquisition device II15. The rotary type The feeder 13 is provided with a through groove 133 for receiving the tapered rollers from the feeder 12, and the image acquisition device II15 is located on both sides of the rotary feeder 13, and the rotary feeder 13 is provided with a tapered roller for sorting. The first sorting mechanism for qualified products and defective products on the end face; the side detection mechanism 2 is located at the qualified product discharge port of the first sorting mechanism, and it includes positioning fixtures 21 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com