DC brushless coreless motor

A DC brushless, hollow cup technology, applied in the shape/style/structure of electrical components, electromechanical devices, winding conductors, etc., can solve problems such as brush wear and tear, and achieve the effects of long life, low heat generation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

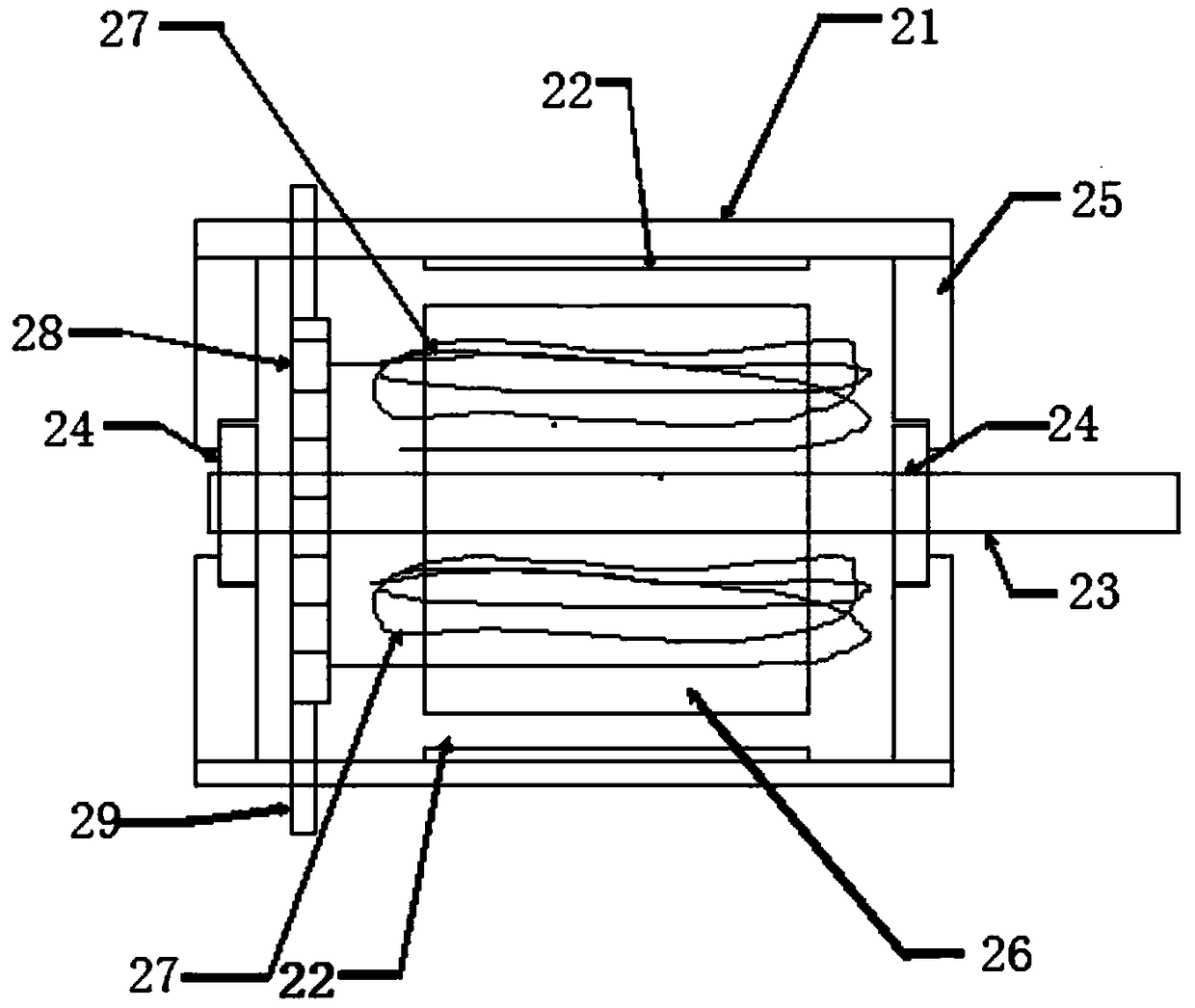

[0023] Such as Figure 4 As shown, a DC brushless coreless motor includes a rotor 2 with magnets, several groups of coils 3, end covers 6, casing 1, and bearings 4, and the rotor 2 with magnets is provided with a rotating shaft 13, so The bearing 4 is sleeved on the rotating shaft 13, the rotating shaft 13 is installed on the casing 1, the casing 1 is connected with the end cover 6, and the several groups of coils 3 are directly fixed on the inner wall of the casing 1. The bearings 4 are located on both sides of the rotating shaft 13 . The casing 1 is insulated from several groups of coils 3 . There are 14 groups of coils 3, all of which are air core coils.

Embodiment 2

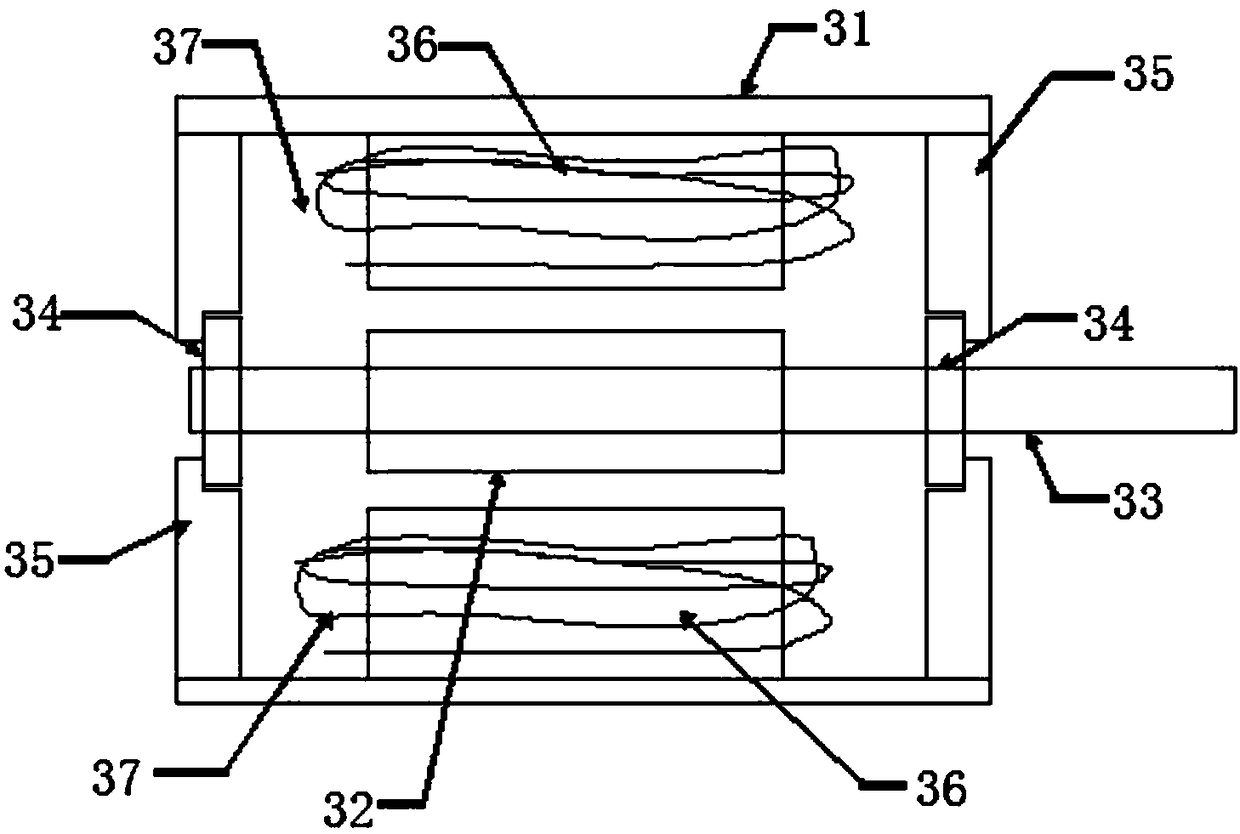

[0025] Such as Figure 5 As shown, a DC brushless coreless motor includes a rotor 2 with magnets, several groups of coils 3, end covers 6, a casing 1, bearings 4, and a rotating shaft 13, and the rotor 2 with magnets is provided with a rotating shaft 13. The bearing 4 is set on the rotating shaft 13, the rotating shaft 13 is installed on the casing 1, the casing 1 is connected with the end cover 6, and the several groups of coils 3 are fixed on the inner wall of the casing 1 through the bracket 7 superior. The bearings 4 are located on both sides of the rotating shaft 13 . The support 7 is insulated from several sets of coils 3 . The coils 3 are all air core coils.

Embodiment 3

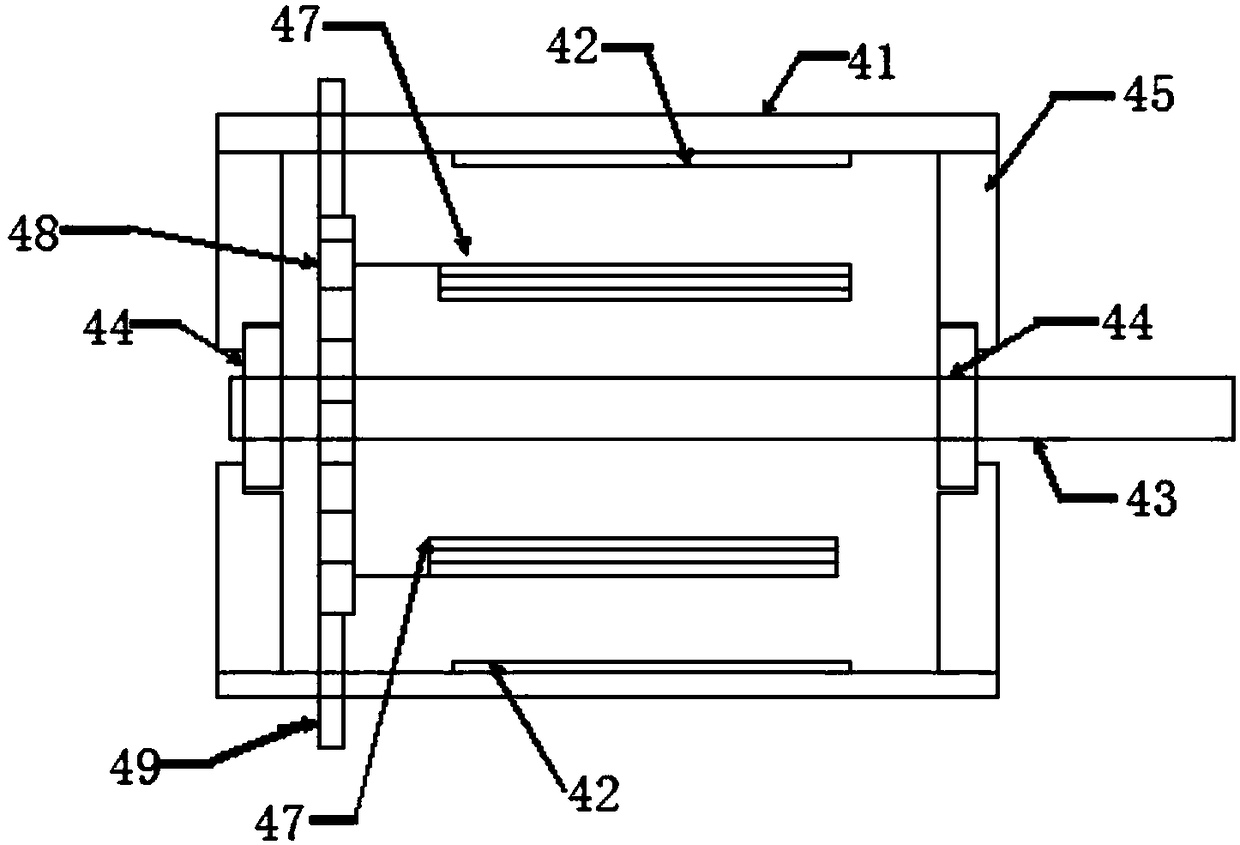

[0027] Such as Figure 6 As shown, a DC brushless coreless motor includes a rotor 2 with magnets, several groups of coils 3, end covers 6, a casing 1, bearings 4, and a rotating shaft 13, and the rotor 2 with magnets is provided with a rotating shaft 13. The bearing 4 is set on the rotating shaft 13, the rotating shaft 13 is installed on the casing 1, the casing 1 is connected with the end cover 6, and the several groups of coils 3 are directly fixed on the end cover 6. The bearing 4 is located on one side of the rotating shaft 13 . The coils 3 are all air core coils. The end cap 6 is insulated from several sets of coils 3 .

[0028] The power supply of the present invention is directly connected to the coil without wear and tear, so the service life is long, and the present invention has the advantages of fast start-up and low heat generation, simple structure and low cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com