Chopped fiber dispersion machine

A technology of chopped fiber and dispersing machine, which is applied in the direction of mixing method, glass manufacturing equipment, solid and solid mixing, etc., which can solve the problems that the original shape and dispersion effect of the fiber cannot be guaranteed, and achieve small wear and good fiber dispersibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

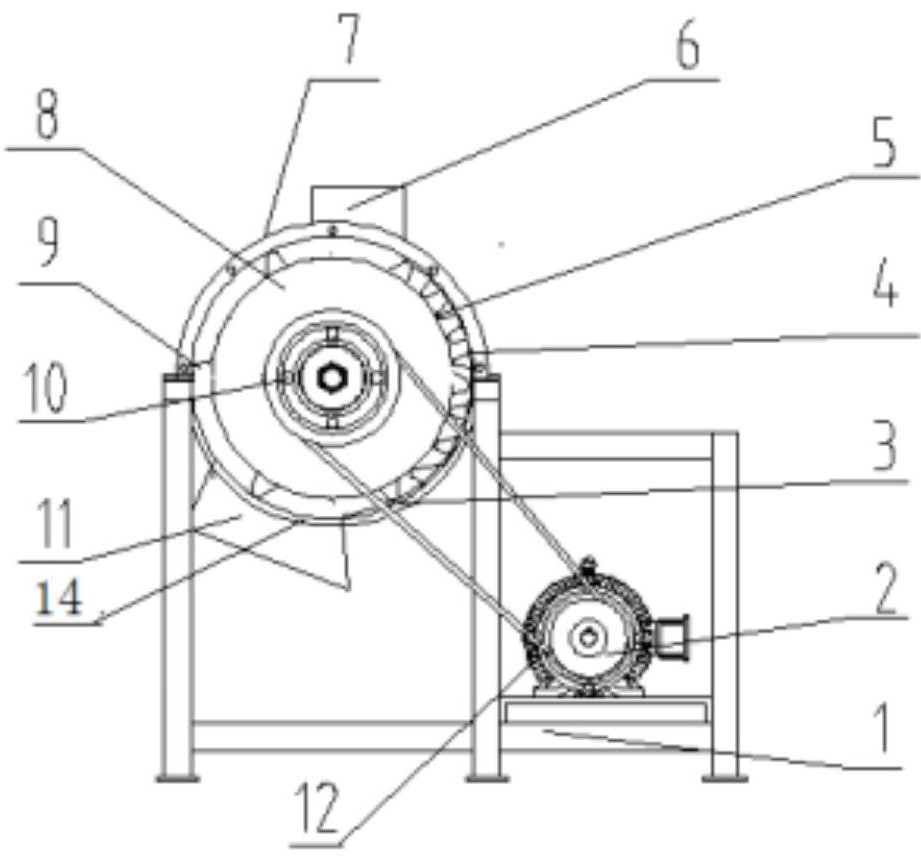

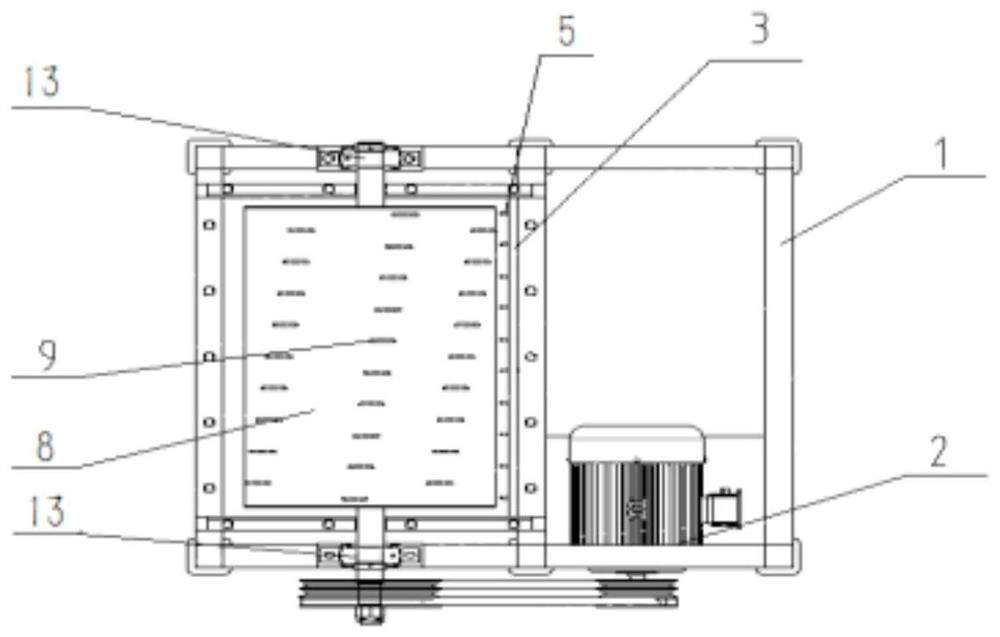

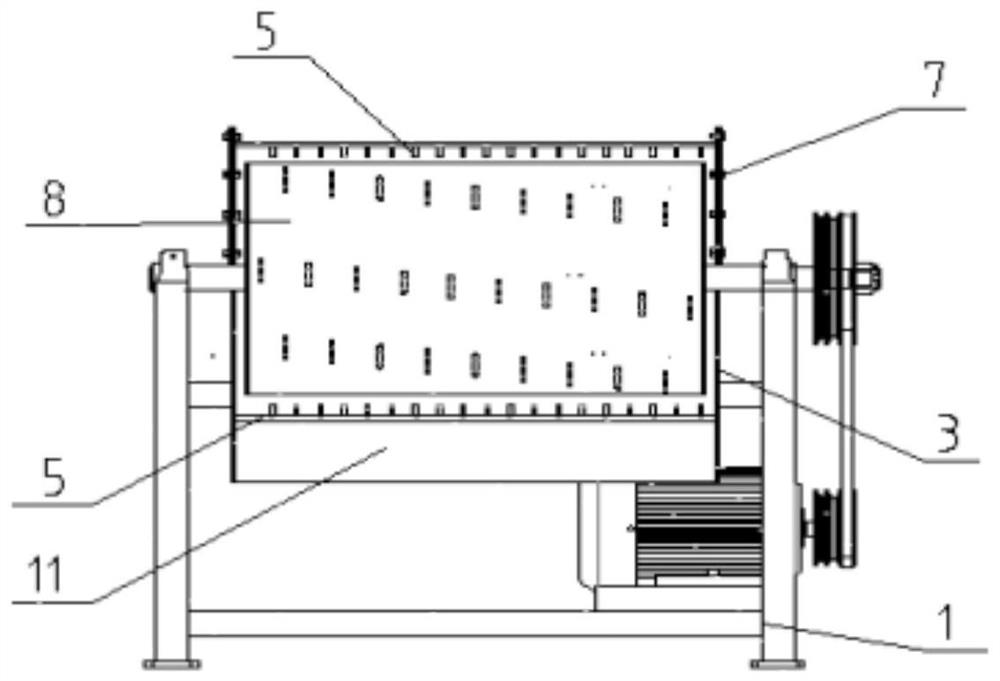

[0025] This embodiment is a glass fiber dispersing machine, including a frame 1, a motor 2, a lower casing 3, a dispersing tooth plate 4, a tooth plate dispersing tooth 5, a feeding port 6, an upper casing 7, a rotating inner cylinder 8, Dispersing teeth 9, large pulley 10, discharge port 11, small pulley 12, bearing seat 13 and lower casing 14 in the inner cylinder. in:

[0026] The semicircular upper casing 7 is fixed on the upper end surface of the frame; the rotating inner cylinder 8 is located below the semicircular upper casing 7, and the two ends of the rotating inner cylinder rotating shaft are installed on the rotating shaft through the bearing seat 12. on the crossbeam of the frame 1; the lower casing 14 is located below the rotating inner tube 8 and fixed between the poles of the frame; the upper casing, the lower casing 14 and the rotating inner The barrels are coaxial, and a circle with the same inner diameter is formed by the upper shell and the lower shell, for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com