Seed sowing wheel component capable of adjusting sowing rate and seed sowing device

A technology of seeding wheel and seeding device, which is applied to the parts of the seeder, can solve the problems of uneven seed sowing, inability to accurately fall into the seed hole, and splashing of seeds everywhere, so as to increase the amount of seeds and realize the amount of sowing The effect of adjustment and easy acquisition of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

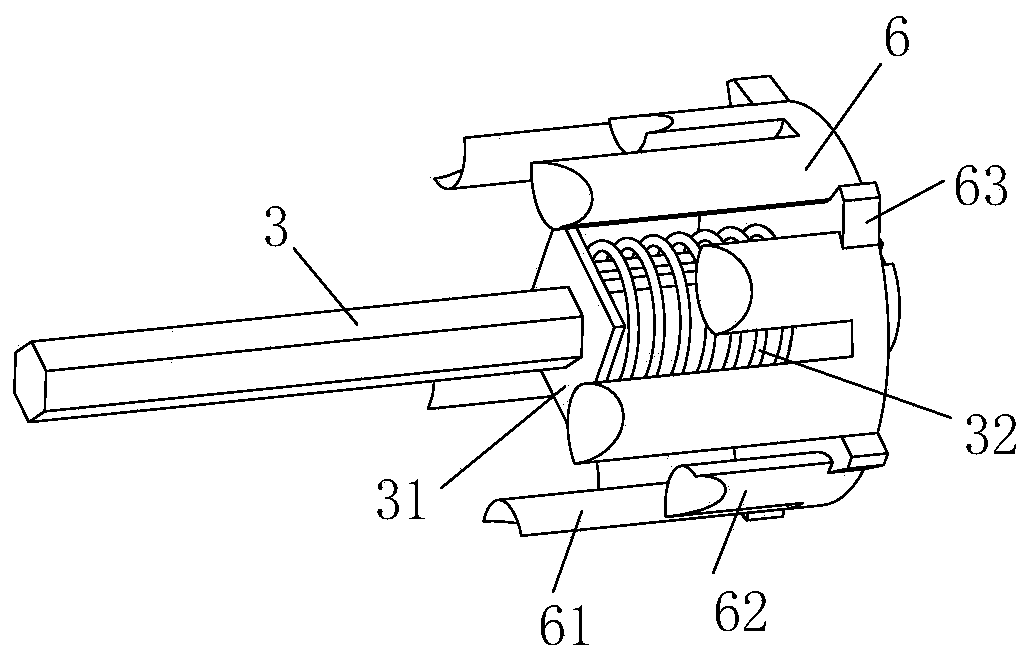

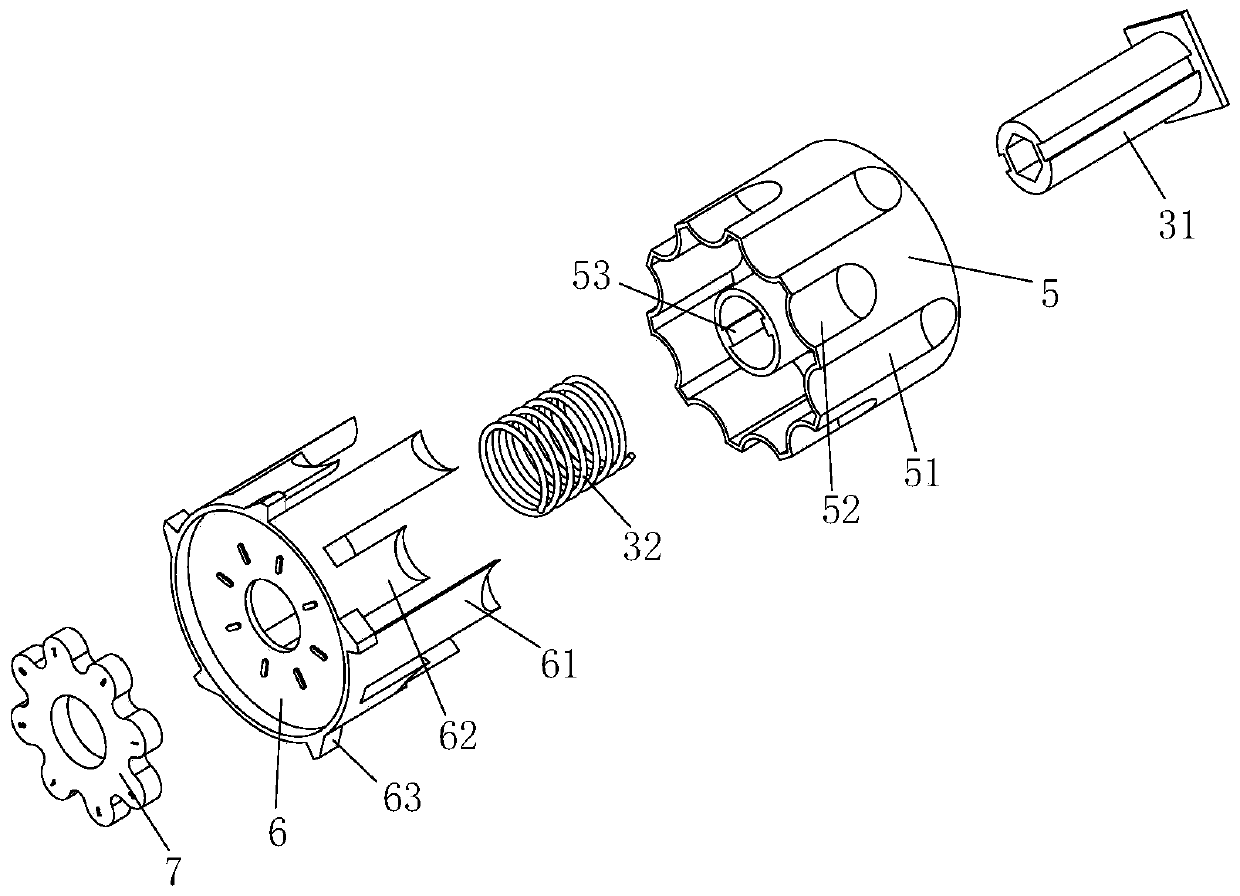

[0042] This embodiment relates to a seed metering wheel assembly capable of adjusting the amount of seeding, which is pivotally arranged in the housing of the seed metering device. Its main structure includes a seed metering wheel, an adjusting shaft, an elastic pusher and an adjusting nut. It is constructed with a cavity that can accommodate seeds, and the size of the cavity can be changed by screwing in or out of the adjusting nut on the adjusting shaft, thereby realizing the adjustment of the sowing amount.

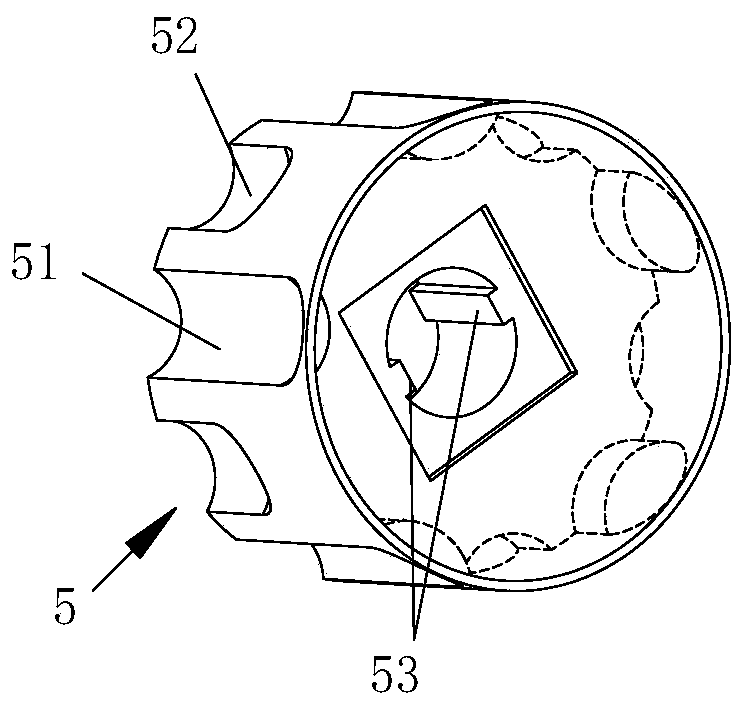

[0043] Based on the above structural design idea, an exemplary structure of this embodiment is as figure 1 As shown, the metering wheel includes a first wheel body 5 and a second wheel body 6 that are coaxially arranged, and the outer peripheral surface of the first wheel body 5 is configured to be arranged in the circumferential direction of the first wheel body 5 and alternately A plurality of cavities with different lengths are distributed at intervals. Each cavity exte...

Embodiment 2

[0051] This embodiment relates to a seed metering device, an exemplary structure such as 6 to Figure 8 As shown, the seed metering device includes a seed metering device housing 2 in which the seed metering wheel assembly capable of adjusting the sowing amount as described in the first embodiment is housed in the seed metering device housing 2 A seed cleaning brush 8 rotating in the same direction as the seed metering wheel is provided, and the bristles of the seed cleaning brush 8 are closely attached to the outer peripheral surface of the seed metering wheel.

[0052] Corresponding to the two rows of cavities 10 on the seed metering wheel described in the first embodiment, a partition plate is constructed on the seed meter housing 2 to form different metering grooves. Of course, it can also be passed on the partition plate A baffle is added to prevent the seeds in the seed box from falling into the seeding trough, so that a single row of cavities 10 can be planted, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com