Sweeping machine for photovoltaic panel

A cleaning machine and photovoltaic panel technology, applied in the cleaning method using tools, photovoltaic modules, photovoltaic power generation, etc., can solve the problems of high cost, complex structure of the cleaning machine, etc., achieve fast cleaning speed, easy control and maintenance, and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

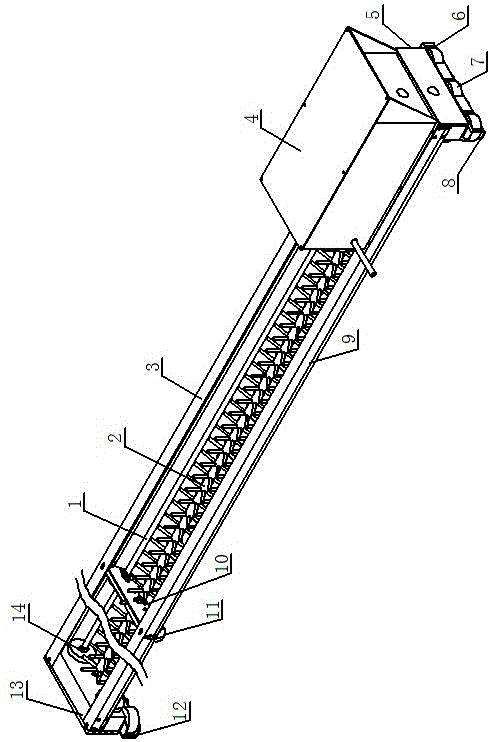

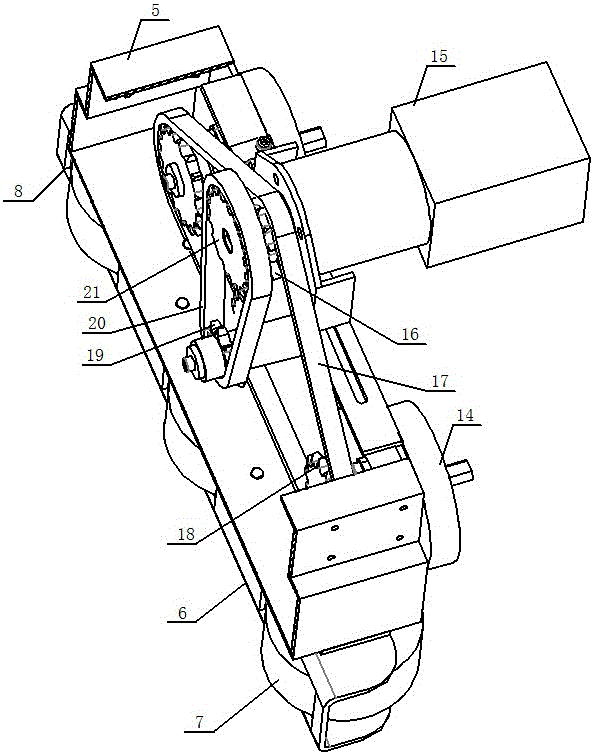

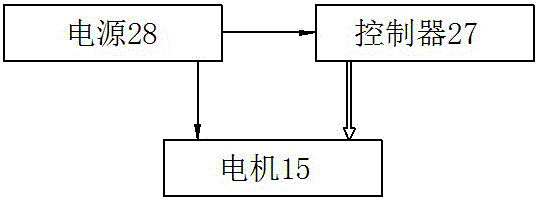

[0037] Example 1:

[0038] as attached figure 1 , attached figure 2 And attached image 3 As shown, a cleaning machine for photovoltaic panels of the present invention includes a frame, a rotatable brush stick 2 mounted on the frame, a rotatable drive shaft 1 mounted on the frame, and a The driving device on the frame, the power supply 28 and the controller 27, the transmission shaft 1 and the brush stick 2 are arranged in parallel, and the two ends of the transmission shaft 1 are equipped with traveling wheels 14 respectively; the driving device is located at one end of the frame, including a motor 15, Driving sprocket I21, driving sprocket II16, driven sprocket I19, driven sprocket II18, chain I20 and chain II17, motor 15 is arranged on the frame, driving sprocket I21 and driving sprocket II16 are coaxially arranged on the motor On the output shaft of 15, the driven sprocket I19 is assembled on one end of the brush stick 2, the driven sprocket II18 is assembled on one en...

Example Embodiment

[0045] Example 2:

[0046] as attached image 3 , attached Figure 4 And attached Figure 5 As shown, this implementation is a further improvement on the basis of Embodiment 1. The difference between this embodiment and Embodiment 1 is: both ends of the brush stick 2 are equipped with drive sleeves, and each drive sleeve is equipped with a brush Traveling wheel; the driving device also includes a driven sprocket III23 with the same diameter as the driven sprocket II18, the driven sprocket III23 is located between the two driven sprockets II18, and the driving sprocket II16, two driven sprockets II18 and the driven sprocket III23 are connected through the transmission of the chain II17, and the driven sprocket III23 drives the driving sleeve close to it to drive the brush walking wheel 22 close thereto. The synchronous cooperation of two brush walking wheels 22 can prevent the brush stick 2 from supporting the bottom in the walking process.

[0047] The end of the brush sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com