Vacuum optical coating machine capable of moving along with workpiece and in-place dynamically monitoring membrane thickness

An optical coating machine, dynamic monitoring technology, applied in vacuum evaporation coating, sputtering coating, ion implantation coating and other directions, can solve the problems of easy failure, low reliability, affecting film thickness accuracy and repeatability, etc. To achieve the effect of simplifying the complex structure, reducing the failure rate and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

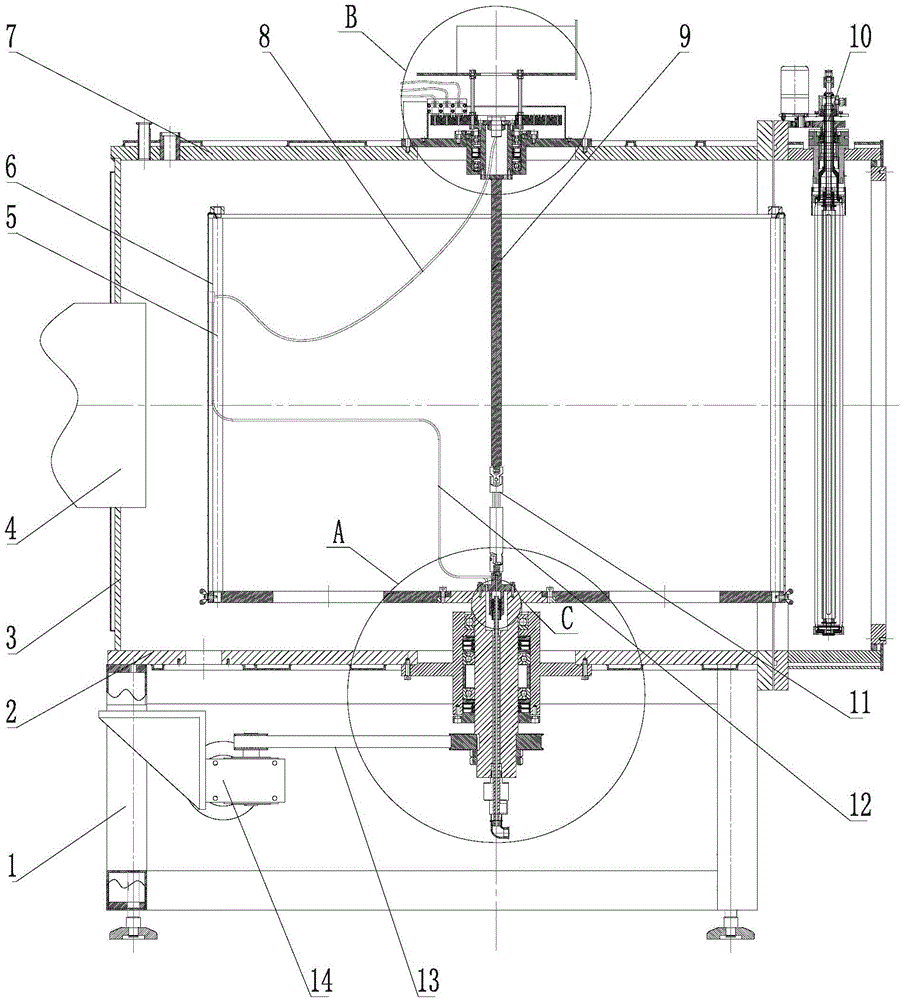

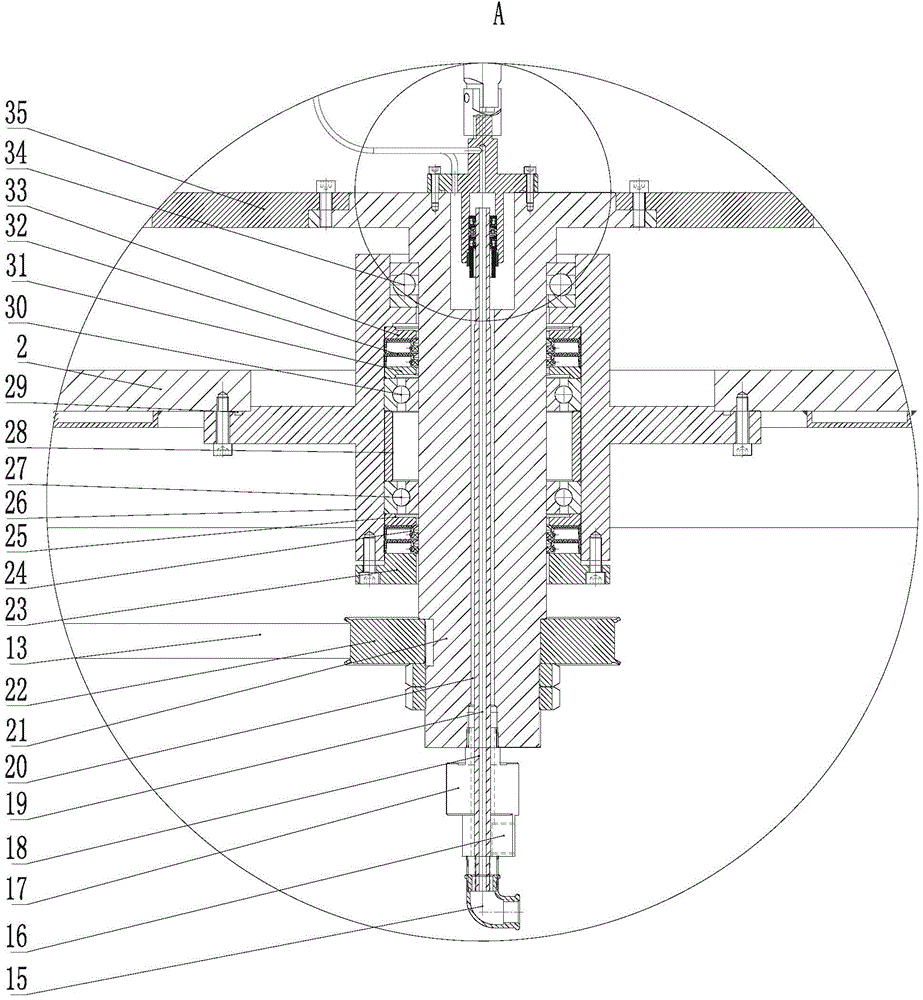

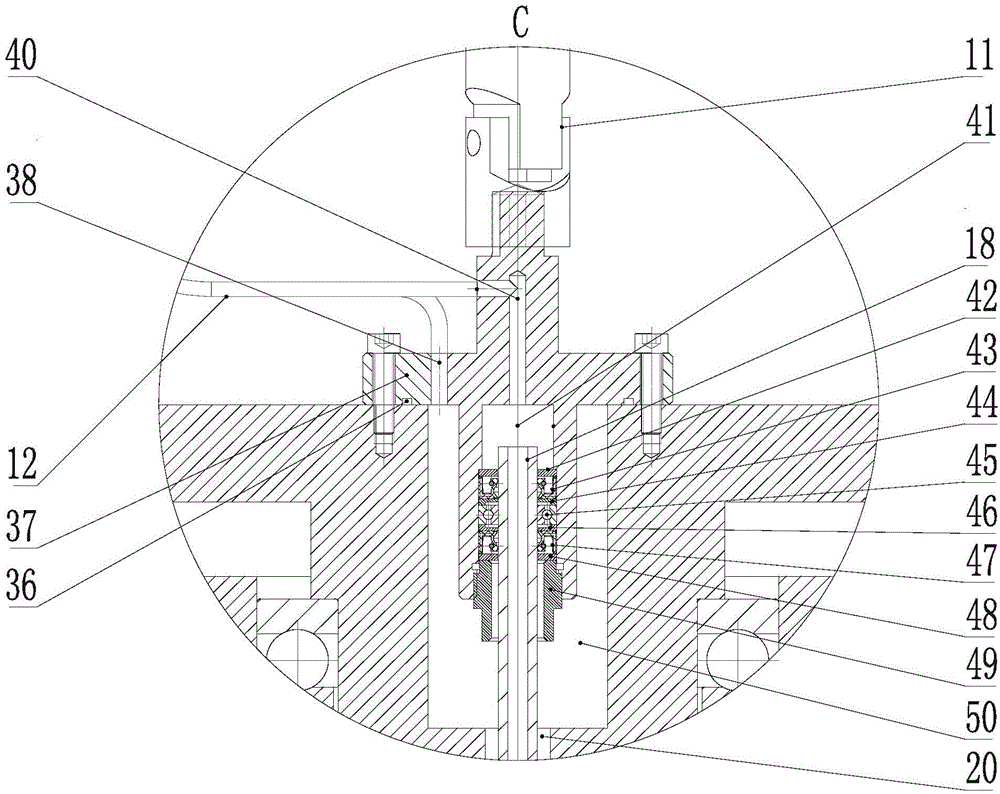

[0033] figure 1 A schematic diagram of the main structure of the vacuum optical coating machine of this embodiment. Such as figure 1 As shown, the vacuum optical coating machine includes a furnace body, a rotating shaft, a workpiece turret 5 , a rotating shaft driving mechanism, a crystal oscillator probe 6 and a film thickness controller host 73 . The furnace body is composed of a furnace wall 3, a furnace body chassis 2 and a furnace body top plate 7. The lower part of the furnace body is supported by a furnace body support 1. The furnace wall 3 is provided with an air extraction port 4 connected with a vacuum unit, so that the furnace body can be removed during coating. Vacuum it. The rotating shaft is vertically installed in the middle of the furnace body, and consists of the lower transmission shaft 21, the upper transmission connector 37, the universal coupling 11, the upper extension shaft 9 and the upper transmission shaft 52, which are connected sequentially from bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com