Test tube cover removal device

A test tube cover and removal technology, applied in the field of medical devices, can solve the problems of low efficiency, sexual infection pollution, low degree of automation and low efficiency, and achieve the effect of simplifying the driving structure, ensuring synchronization, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

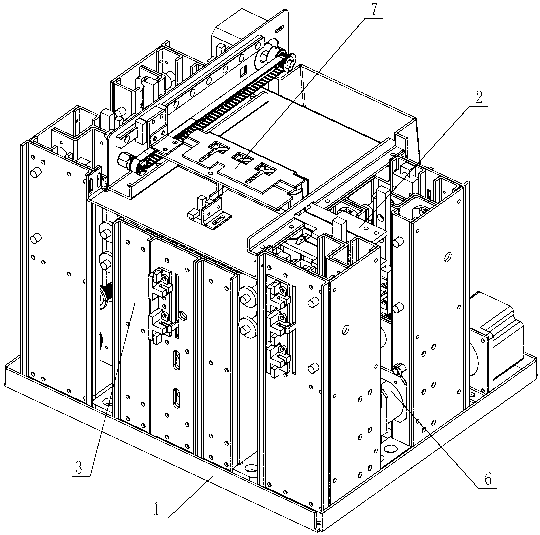

[0042] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

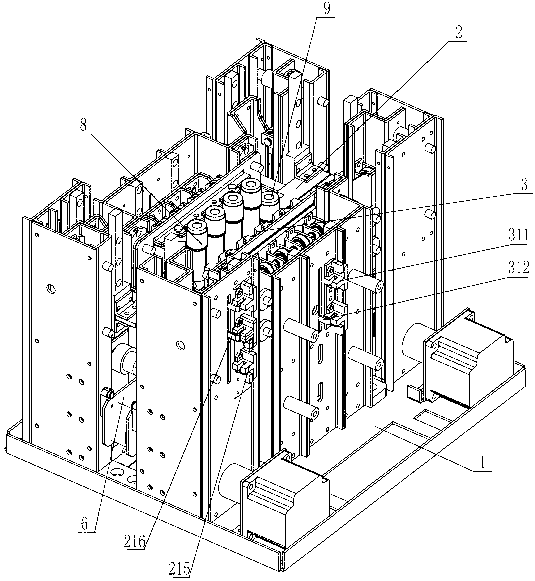

[0043] 1. The description of clamping lifting and cover opening mechanism 2 is as follows:

[0044] See Figure 4 , Figure 5 , Figure 6 , the clamping lifting and cover opening mechanism 2 includes a cover clamp 201 arranged horizontally, the cover clamp 201 can move up and down, and the two ends of the cover clamp 201 are fixedly connected with the sliders in the first linear guide rail pair 202 respectively, and the cover clamp Both ends of 201 are slidably supported on the cam mounting base 203 through the first linear guide pair 202. The cam mounting base 203 is equipped with a cam-204, and the other side of the cam-204 is provided with a cam guide with a guide slope-2051. Plate 1 205, cam 1 204 face guide slope 1 2051, cam guide plate 1 205 is slidably supported on frame 1 207 through second linear guide pair 206, frame 1 207 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com