Independent weight loading-unloading dead-load type torque measurement device

A technology of torque measurement and static weight, which is applied in the direction of measuring devices, calibration/testing of force/torque/power measuring instruments, instruments, etc., can solve problems such as difficulty in automation, complicated control devices, and slow loading speed, and achieve a solution The effect of slow loading speed, simple drive structure, and enhanced accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

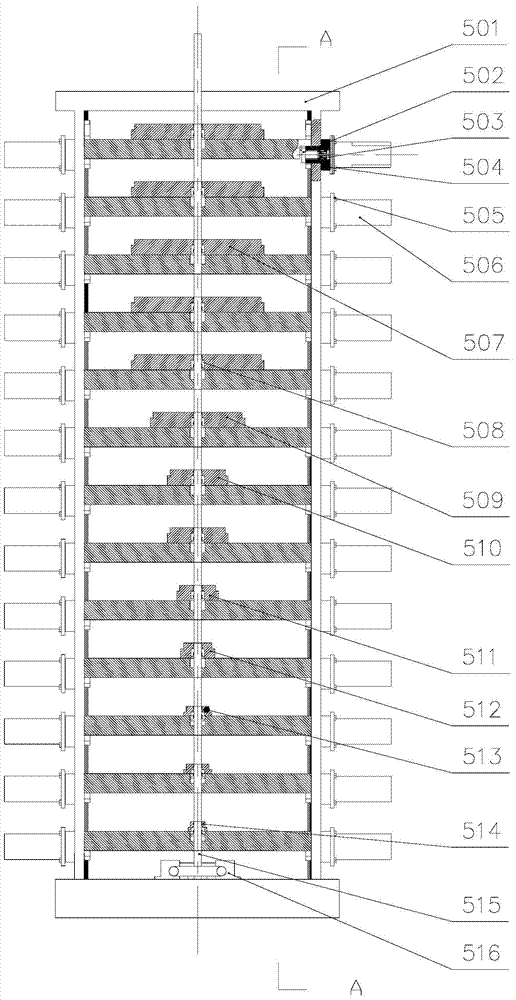

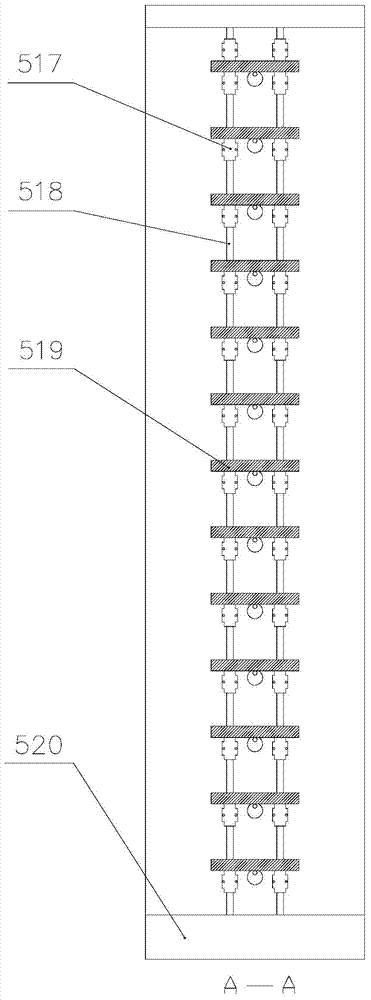

[0026] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

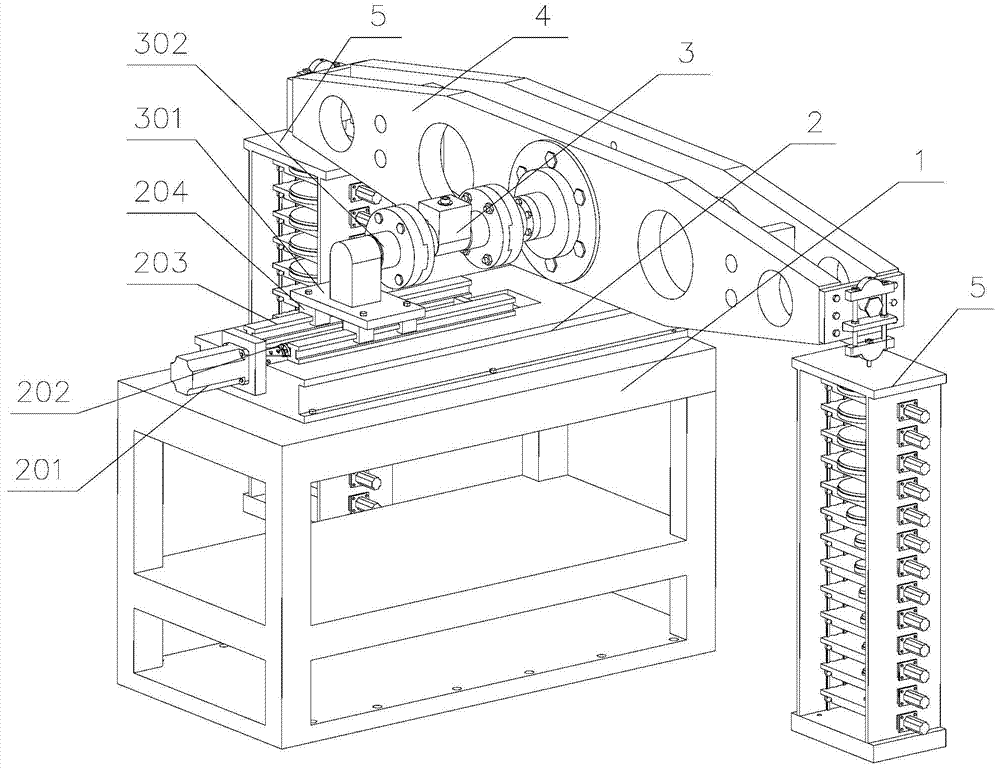

[0027] See attached figure 1 , the independent loading and unloading weight static weight type torque measuring device of the present invention comprises:

[0028] Supporting device 1, described supporting device 1 is a square frame;

[0029] The loading device 2 fixed on the upper surface of the support device 1, the loading device 2 includes a stepping motor A201, a ball screw 202, a screw nut, a nut support seat, a slide rail 203 and a guide rail slider 204, the slide The rail 203 is fixed on the upper surface of the support device 1, the slide rail 203 and the guide rail slider 204 form a moving pair, and the ball screw 202 and the lead screw nut form a helical pair, and the lead screw nut is connected to the screw nut through the nut support seat. The slider is connected, and the output end of the stepping motor is connected with the ball screw 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com