Friction liner-hoisting steel wire rope dynamic friction drive test device and friction liner-hoisting steel wire rope dynamic friction drive test method

A technology of friction lining and dynamic friction, which is applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problem of not being able to analyze the dynamic contact between the steel wire rope and the friction lining and the friction transmission behavior, to simulate the friction transmission behavior, and to explore the dynamic peristalsis Research on the influence of slip state and other issues, to achieve the effect of wide practicability, complete functions and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

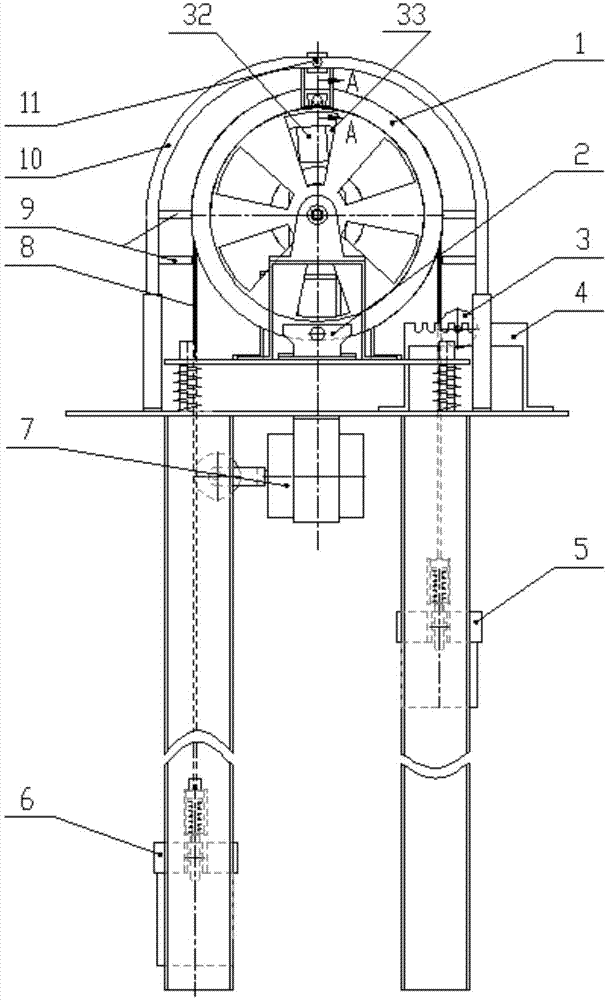

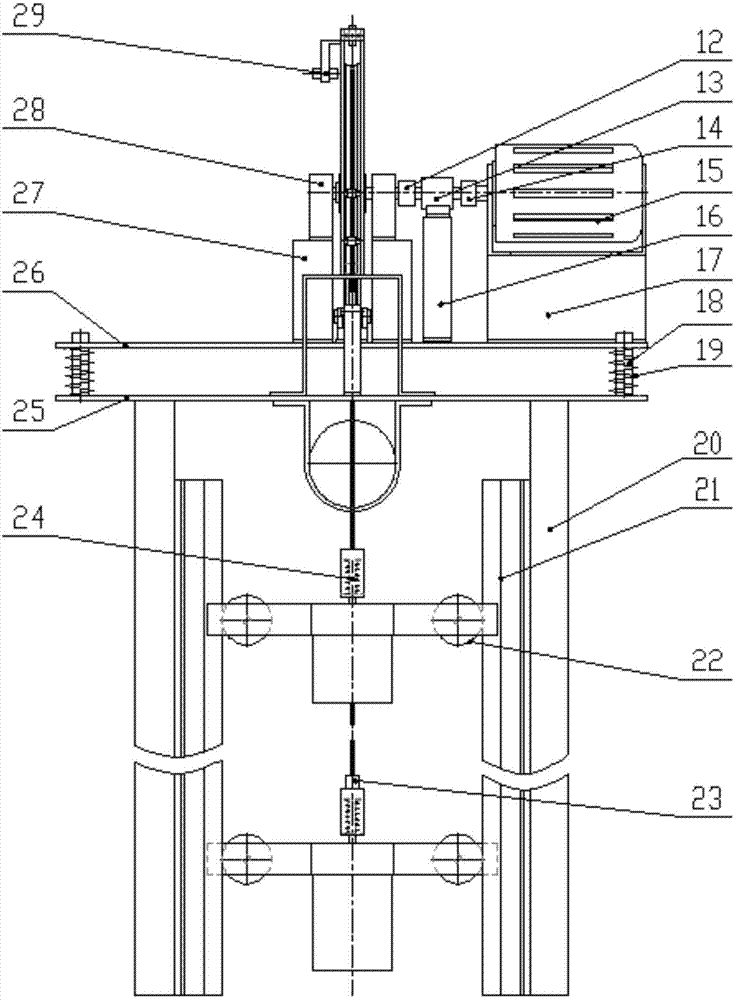

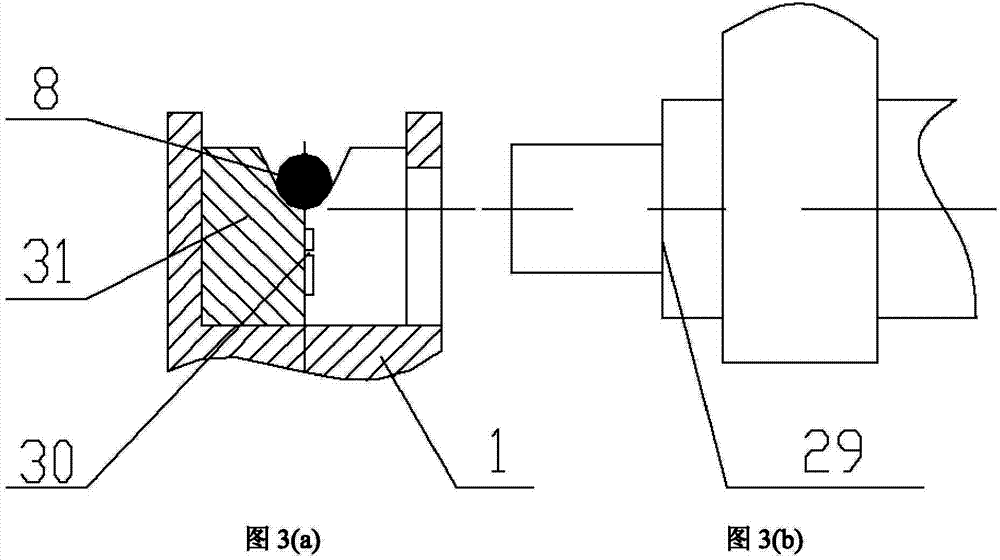

[0033] like figure 1 , figure 2 , Fig. 3(a) and Fig. 3(b) and Fig. 3(b) are a kind of friction lining-hoisting wire rope dynamic friction transmission test device, including base frame, driving mechanism, friction transmission mechanism, enclosing angle adjustment mechanism, vibration excitation mechanism , steel wire rope 8 and condition monitoring mechanism, below just each part is specifically described.

[0034] The base frame includes a column 20, a lower support platform 25 and an upper support platform 26. The column 20 is symmetrically arranged, and the lower support platform 25 is horizontally fixed on the column 20. On the lower support platform 25, four pin shafts are uniformly fixed and arranged through a threaded structure. 18. A spring 19 is sleeved on the pin shaft 18, a pin hole corresponding to the position of the pin shaft 18 is provided on the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com