Non-destructive testing method for natural frequency of transverse vibration of non-fully grouted anchoring bolt in coal mine

A technology of lateral vibration and natural frequency, which is applied to vibration measurement in solids, vibration measurement, measurement device, etc., to achieve the effect of simple and convenient installation and connection, and short detection time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

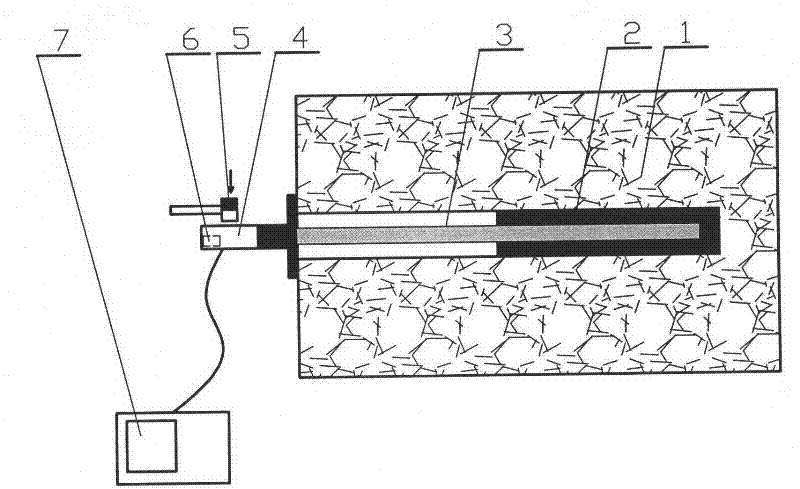

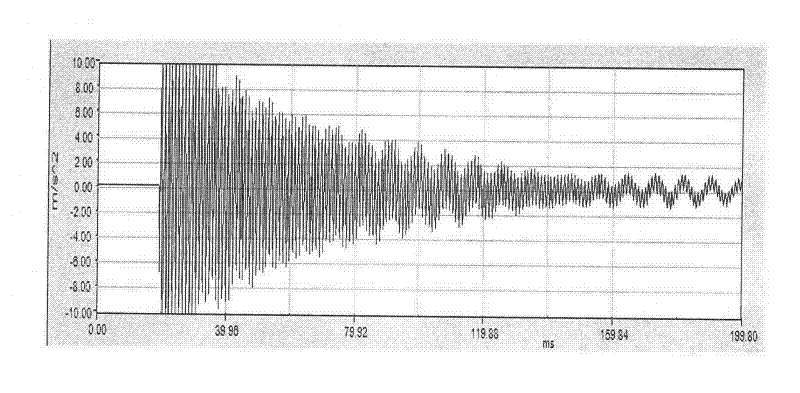

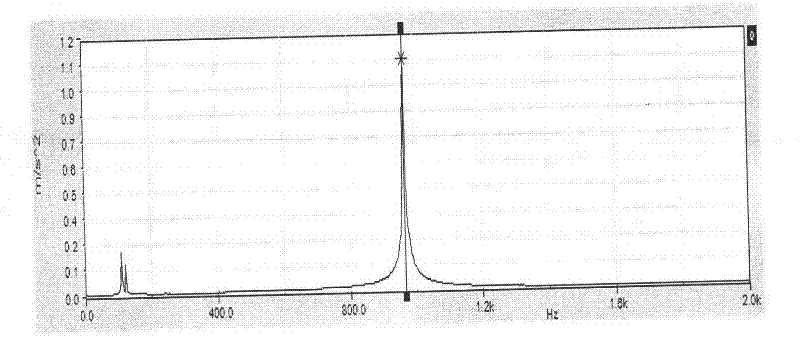

[0017] In the accompanying drawings, a non-destructive detection method for the natural frequency of lateral vibration of a non-full-length bonded bolt in coal mines, the detection steps are: connect the sensor connection device 4 and the sensor 6 to the exposed end of the bolt 3; The connection device 4 applies a normal excitation force to cause the anchor rod 3 to generate lateral vibration; the vibration acceleration of the anchor rod 3 is collected by the sensor 6, and the acceleration signal is transmitted to the detector 7; the detector 7 converts the received acceleration analog signal to Acceleration digital signals are generated and stored; at the same time, frequency spectrum analysis is performed on the collected signals to obtain the natural frequency of the anchorage system of the measured bolt 3.

[0018] in the attached figure 1 Among them, a device for realizing a non-destructive detection method for the natural frequency of lateral vibration of a non-full-leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com