Method for processing fuel cell carbon bipolar plate with check conducting wire

A fuel cell and processing method technology, which is applied in the directions of fuel cell parts, fuel cells, battery electrodes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

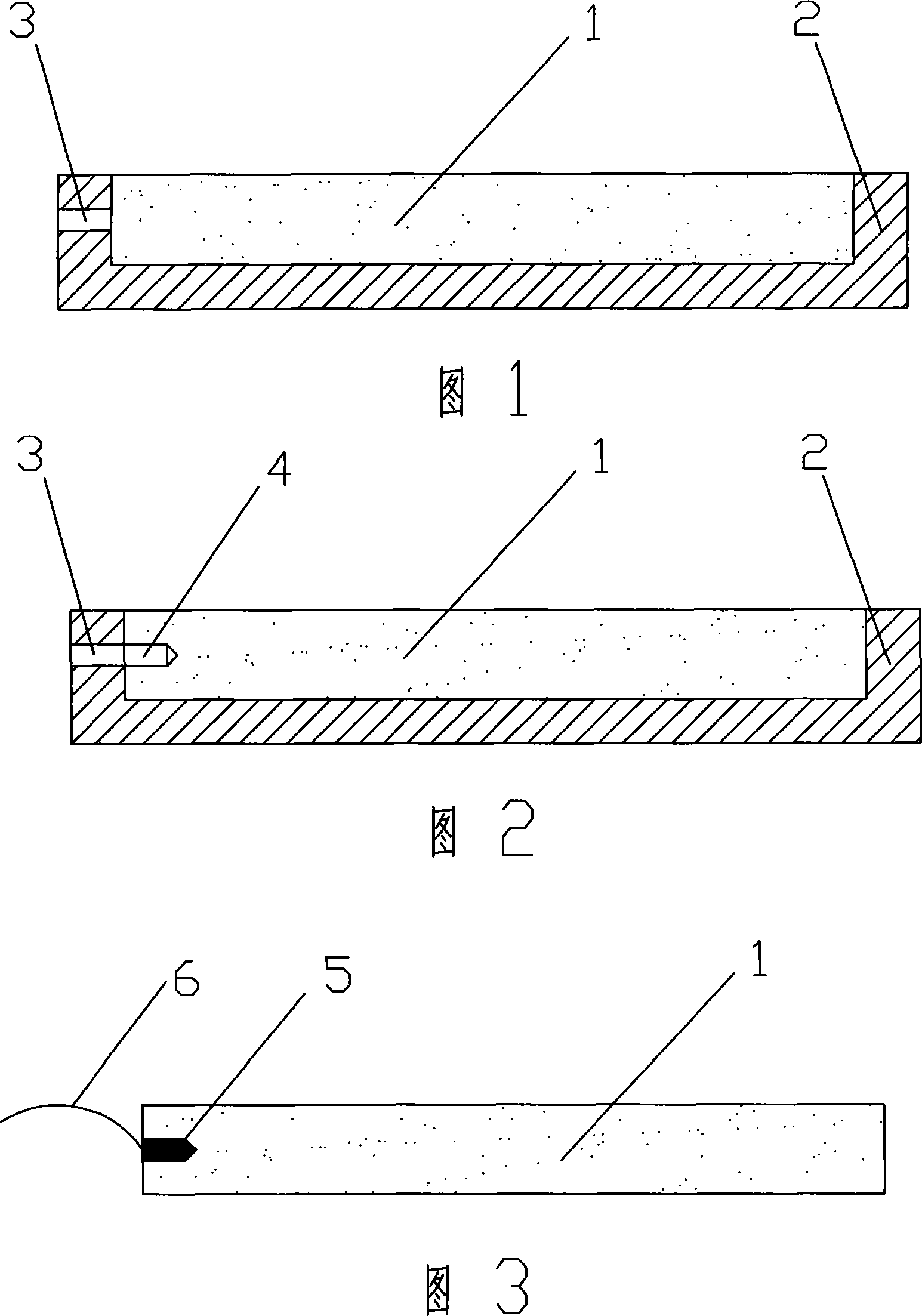

[0022] As shown in the figure: the production steps are as follows:

[0023] ①. First process the carbon bipolar plate body 1 in the traditional way, and the carbon bipolar plate body 1 is plate-shaped. And a processing area is reserved around the carbon bipolar plate body 1 for setting a sealing layer or contacting with the gasket during installation. The thickness of the carbon bipolar plate body 1 is 1 mm or 4 mm or 8 mm or 10 mm or 12 mm or 15 mm, that is, it can be controlled between 1 mm and 15 mm.

[0024] 2. Place the carbon bipolar plate body 1 processed in the previous step in the mold groove 2, and a tooling hole 3 is provided on the side of the mold groove 2. The diameter of the tooling hole 3 is 0.5 mm or 1 mm or 2 mm or 3 mm or 4 mm or 5 mm, that is, between 0.5 mm and 5 mm. For convenience, tooling holes 3 can be provided on each side of the mold groove 2, and drilling can be selected according to needs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com