Three-cone bit for horizontal well and hard formation well

A technology for hard formations and horizontal wells, applied in the direction of drill bits, drill pipes, drill pipes, etc., can solve the problems of accelerated tooth wear and fracture, poor removal of bottom-hole cuttings, and wear, so as to improve the effective service life and benefit Drilling efficiency, enhanced cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

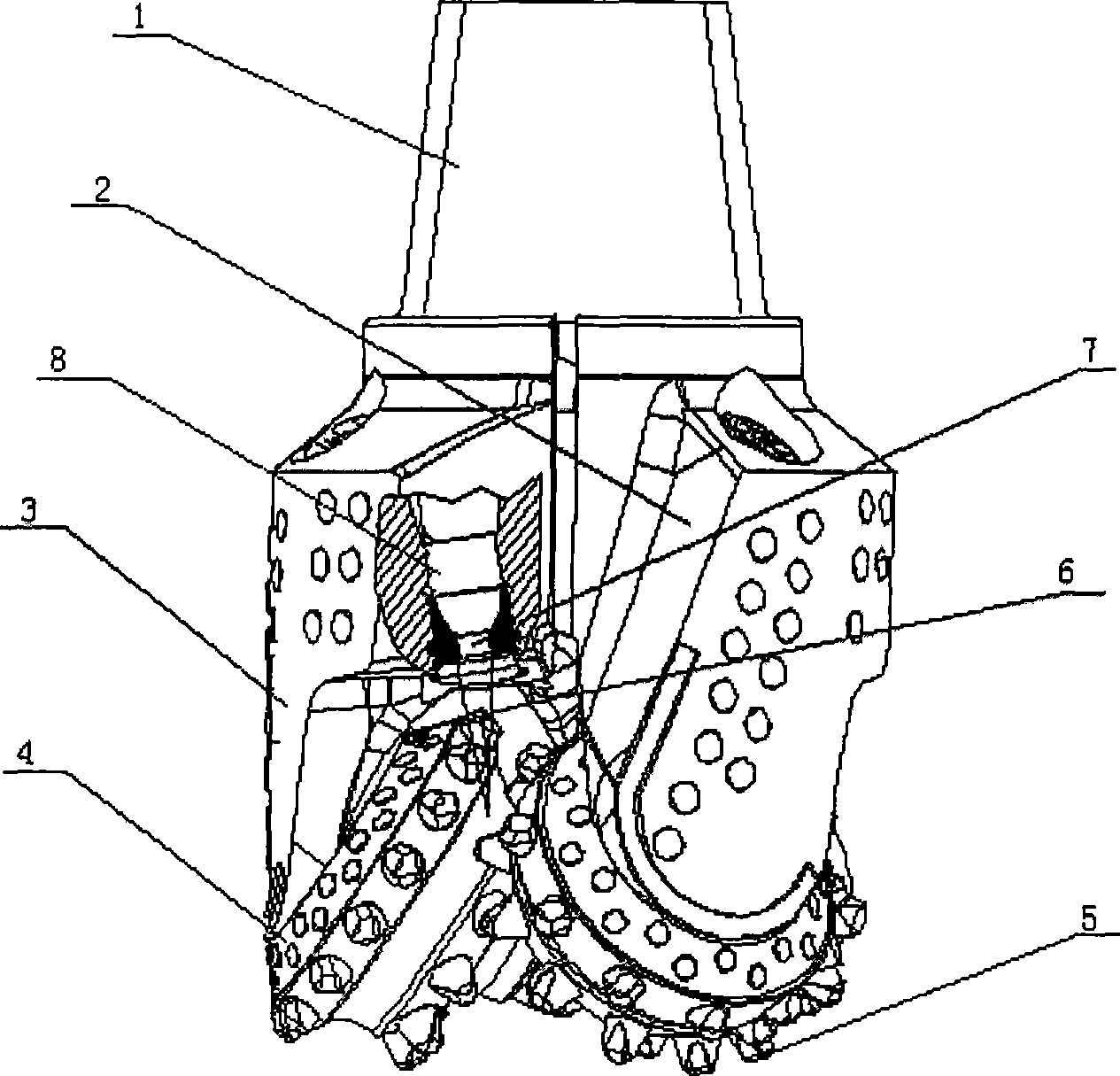

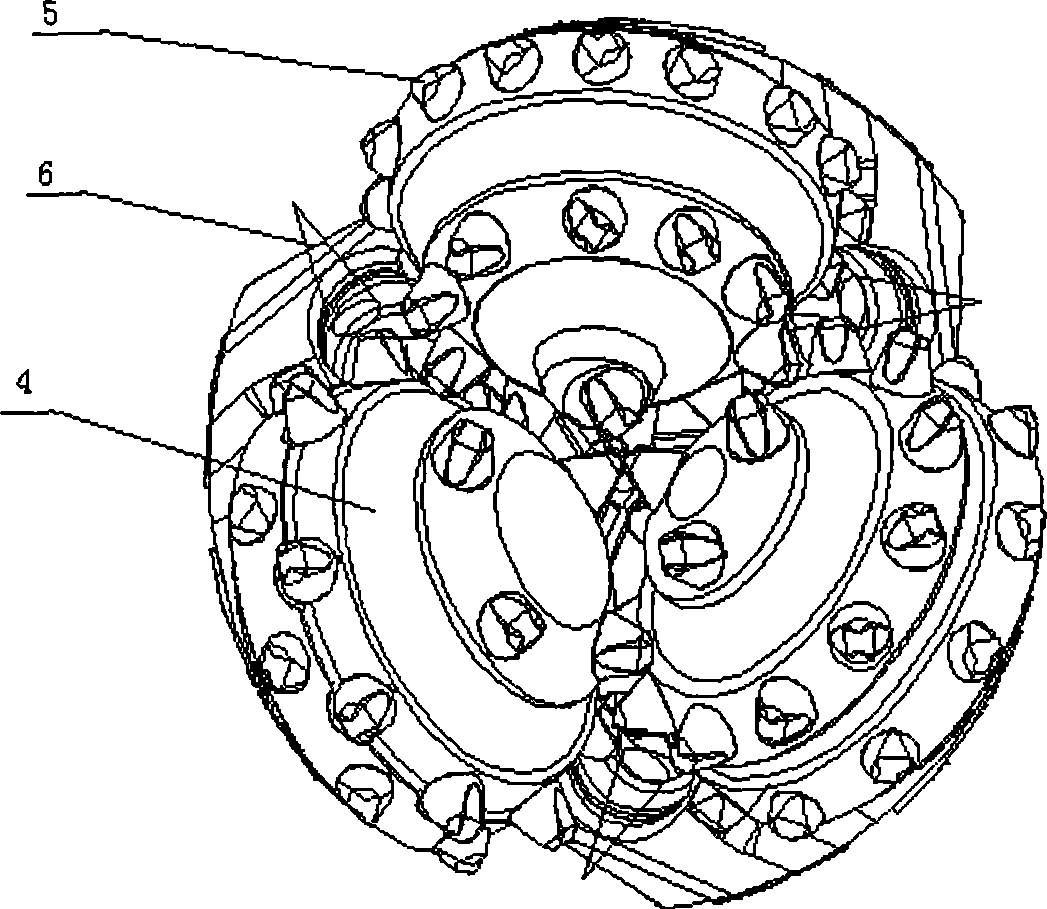

[0013] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0014] It is a three-cone drill bit, including three palms 3 and a cone 4 installed at the lower end of the palm. The upper parts of the three palms are connected together by welding to form a drill body. The upper part of the drill body is provided with tapered threads. 1. It is used to connect with the drill pipe; a gauge tooth is installed on the back side of the upper part of the back of the palm close to the back side of the back of the palm, or the upper back side of the back of the palm extends back for a distance. Gauge teeth are installed on the back, and the gage teeth are embedded on the back of the palm. 2 to 3 rows can be set up and down, and each row has 2 to 3 gage teeth, which can be arranged in a staggered interval. The gage teeth are diamond composite. Teeth or hard alloy teeth form the gauge surface of the upper part of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com