Vibration enhanced device of electric vibration table

An electrodynamic vibration table, vibration enhancement technology, applied in the direction of measuring device, vibration test, machine/structural component test, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

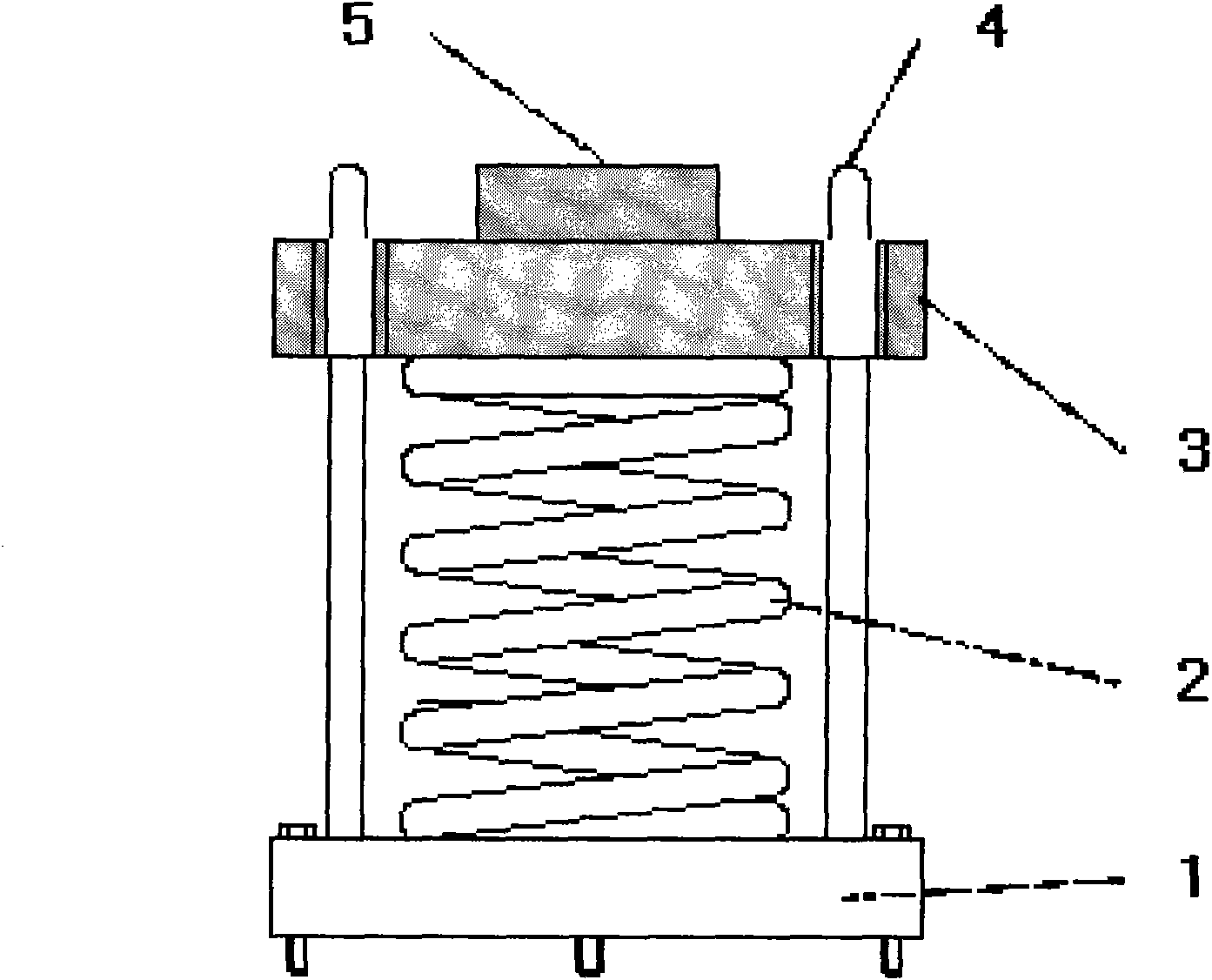

[0018] See attached figure 1 As shown, the vibration enhancement device of the electric vibration table of the present invention includes a base 1 , a spring 2 , a test bench 3 , a guide rod 4 , and an additional mass 5 . The base 1 is rigidly installed on the vibration table, and a compression spring 2 is connected between the base 1 and the test bench 3, and the compression spring 2 is a YII type compression spring. The vibration table composed of the base 1 is connected with the test bench 3 through the spring 2 to form a vibration system, and the spring 2 and the test bench 3 are required to be installed on the same central axis. When the vibrating system is working, the vibrating table performs sinusoidal reciprocating motion, driving the test bench 3 to vibrate. Near the resonant frequency of the spring-mass system co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com