Multi-rope winder steel wire rope tension test method and device thereof

A multi-rope hoist, tension detection technology, applied in tension measurement and other directions, to achieve the effect of easy archiving, low labor intensity, and accident prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

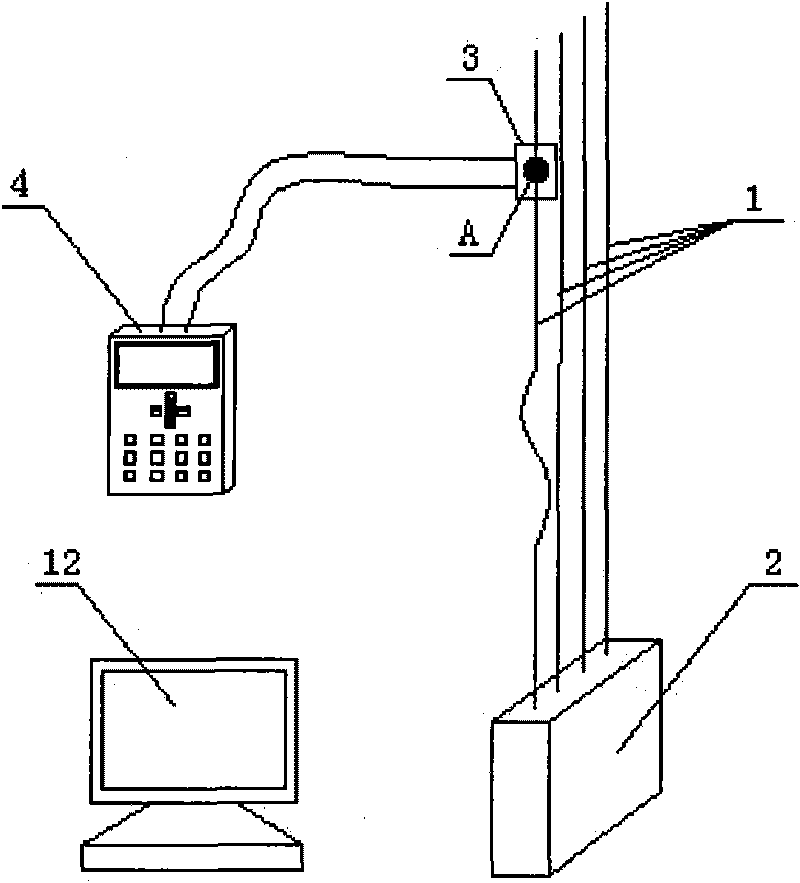

[0027] Such as figure 1 ,Such as figure 2 and image 3 , the present embodiment is a detection method for realizing the steel wire rope tension of a multi-rope hoist, including a measurement method for the vibration propagation period t of the steel wire rope. The method is to first measure the length L of the steel wire rope 1 to be tested, and the linear density ρ of the steel wire rope 1; The acceleration sensor 3 is fixedly connected on the steel wire rope 1 to be tested, and the steel wire rope 1 is hit vertically by the impact force, so that the steel wire rope 1 produces a lateral vibration, and the propagation period t of the vibration wave on the steel wire rope 1 is detected; then the above-mentioned L, ρ and t is substituted in the tension calculation formula (1) of steel rope 1, calculates the tension force of steel rope 1, and the calculation formula (1) of the tension force of described steel rope 1 is specifically deduced as follows:

[0028] According to the...

Embodiment approach 2

[0048] Such as figure 1 , the present embodiment is a detection device implementing a multi-rope hoist wire rope tension detection method, the measurement device is composed of an acceleration sensor 3 , a tension calculator 4 and a tension analysis system 12 .

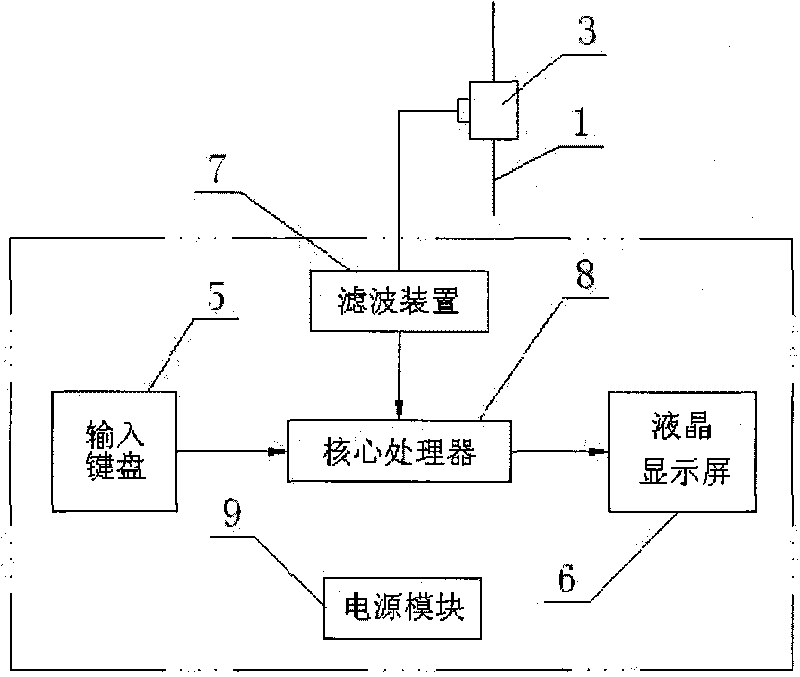

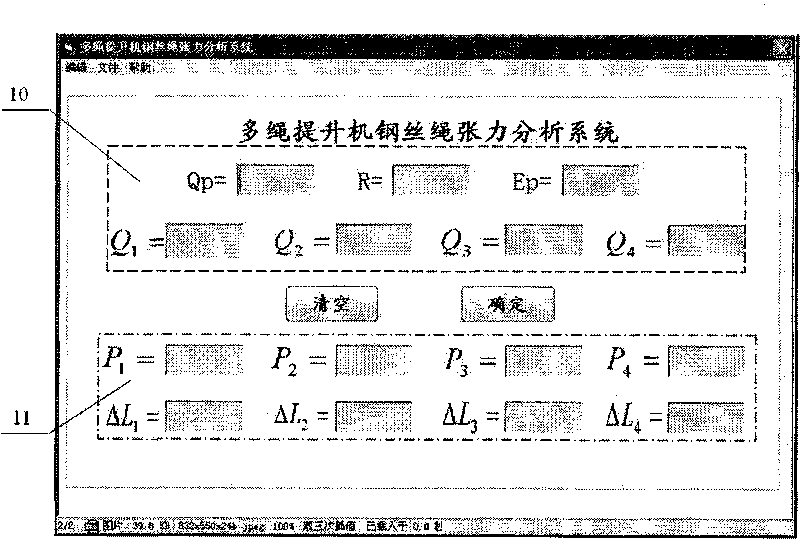

[0049] Such as figure 2 , the internal module composition of detection device comprises input keyboard 5, liquid crystal display screen 6, filtering device 7, core processor 8, power supply module 9; Its specific composition is: acceleration sensor 3 gathers acceleration data signal, and the data signal that gathers Transmit to filtering device 7, transmit to core processor 8 after filtering, core processor (8) records the time difference t of two times of acceleration peak value occurrences at the connection point of steel wire rope (1) and acceleration sensor (3), core processor 8 Calculate the wire rope terminal load Q by formula (I) i , the core processor will compute the result Q i Displayed to the user throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com